INTRODUCTION

GENERAL DESCRIPTION

McQuay type ALP SEASONCON air cooled condensing units

are designed for outdoor installations and are compatible with

either air handling or chilled water systems. Each unit is

com-

pletely assembled and factory wired before evacuation, charg-

ing and testing, and comes complete and ready for installa-

tion. Each unit consists of twin air cooled condensers with

integral subcooler sections, multiple accessible hermetic

com-

pressors, complete discharge piping and suction connections

for connection to any air or water cooling evaporator.

The electrical control center includes all safety and

operating controls necessary for dependable automatic

operation except for the cooling thermostat since this is

somewhat dependent on the unit application. Condenser fan

motors are fused in all three conductor legs and started by

their own three-pole contactors. Compressors are not fused

but may be protected by optional circuit breakers, or by field

installed fused disconnect.

NOMENCLATURE

A L P

-

080 C

T

CESIGN

;/II’-~‘h*:,.;r

NOMINAL CAPACITY (TONS)

INSPECTION

When the equipment is received, all items should be carefully

be checked before unloading the unit

to

ba sure that it agrees

checked against the bill of lading to insure a complete ship- with the power supply available. Physical damage to unit after

ment. All units should be carefully inspected for damage upon

acceptance is not the responsibility of

McQuay.

arrival. All shipping damage should be reported to the

car-

NOTE: Unit shipping and operating

weights

are available

rier and a claim should be filed. The unit serial plate should

in the physical data tables on pages 10 and

1

1.

INSTALLATION

NOTE: Installation and maintenance are to be performed only by qualified personnel who are familiar with local codes

and regulations, and experienced with this type of equipment. CAUTION: Sharp edges and coil surfaces are a potential

injury hazard. Avoid contact with them.

HANDLING

Care should be taken to avoid rough handling or shock due

to dropping the unit. Do not push or puli the unit from anything

other than the base, and block the pushing vehicle away from

the unit to prevent damage to the sheetmetal cabinet and end

frame (see Figure 1).

Never allow any part of the unit to fall during unloading or

Figure

1.

Suggested Pushing Arrangement

BLOCKING REQ’D.

ACROSS FULL WIDTH

I

i

n

moving as this may result in serious damage.

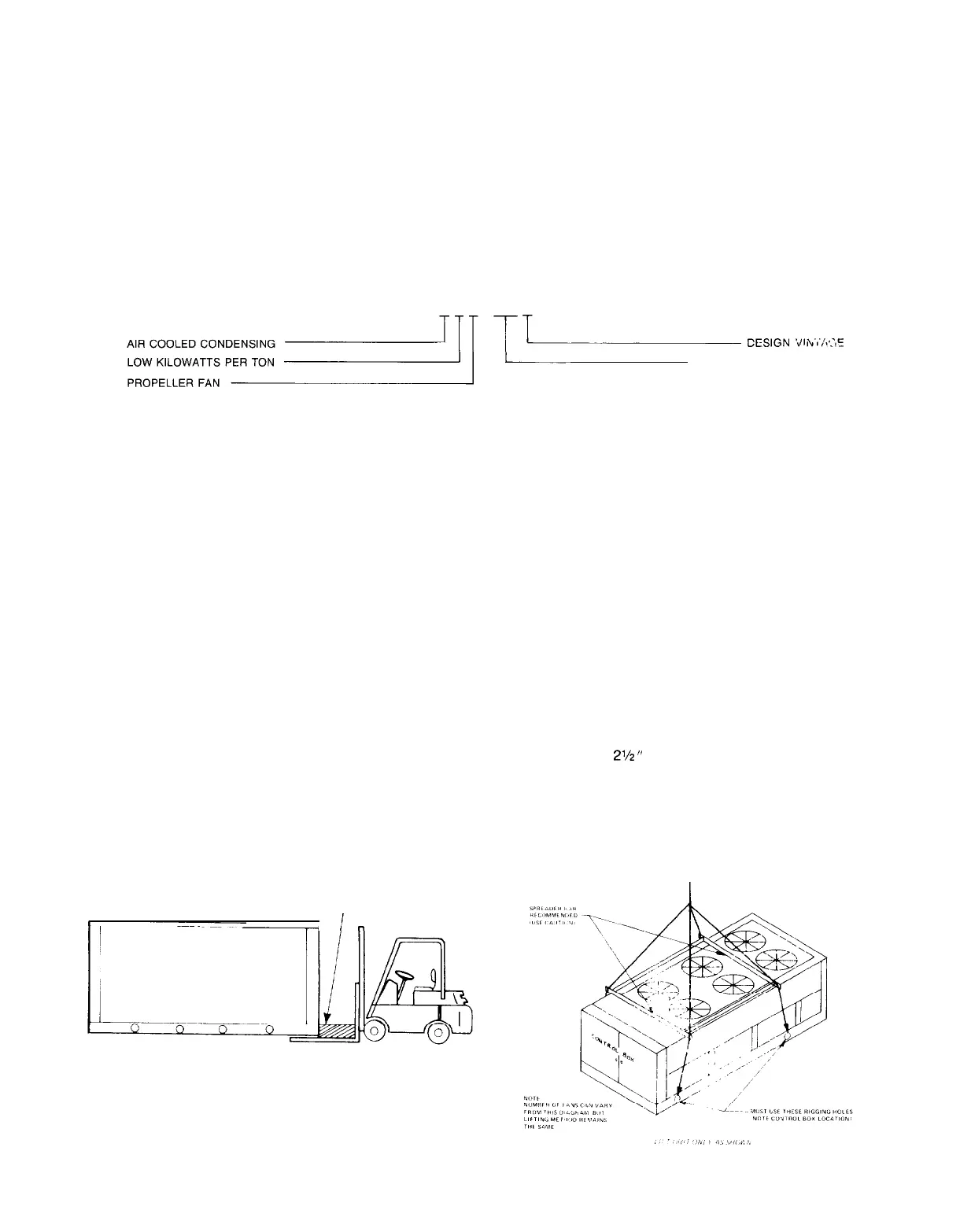

To lift the unit,

2%”

diameter lifting holes are provided in

the base of the unit. Spreader bars and cables should be ar-

ranged to prevent damage to the condenser coils or unit

cabinet (see Figure 2).

Figure 2. Suggested Lifting Arrangement

IM 269 I Page 3

Loading...

Loading...