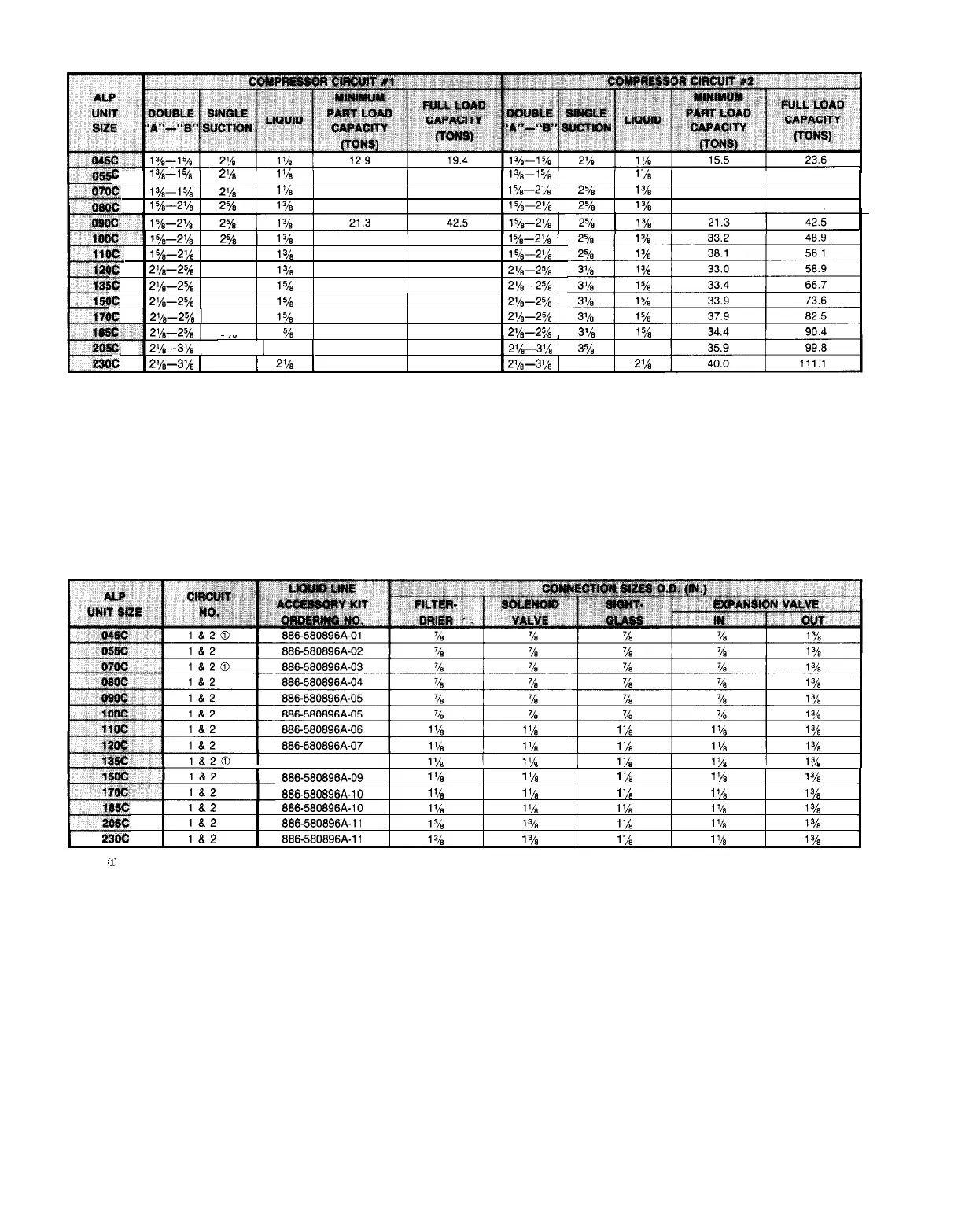

Table 7. Recommended line sizes

c

1

vi-1

5/a

2%

1%

15.3 23.6

IYe-

% 2%

1

‘/s

18.5

29.1

14.7 29.0

t

17.9 35 3

1%--15/g

a!¶

1

‘/a

t

5/8-2’/8

25/n

%

15/s--2’h 2%

1%

16.6 37.6

15h--2’h

2%

1

YE

16.6 37.6

1%

33.2

48.9

t

%-2’/a

1%-2%

2% 1%

36.1 56.1

t5/8-2’/!¶

I$

2%-25/s 3%

1%

33.0

56.9

2’/8-2%

irr:

.%-25/n

3% 1%

33.4 66.7

2’%-2%

tc

I 2%-25/n

I

3%

t

% 33.9 73.6

2%-25/e

E

f

2%-25/e

I

3%

1%

37.9

82.5

2%-25/s

3%

1

=/n

34.4 90.4 2%-25/a

~,I

,

II

,

.”

._

,

3’/a

1%

C

3%

I

2%

I

35.9

99.6

1

2+-31/s

I

35/s

2%

w

1

Wi-3%

1

3%

1

2%

1

40.0

111.1

1

Wi-3%

1

3% 2%

NOTES:

Recommended line sizes shown in the above table are based on the unit

for oil entrainment should be checked and where necessary double

suc-

operating conditions between 40°F and 45°F saturated suction temperature

tion risers should be utilized. See Table 5.

page

6.

and condenser entering air temperature of 95°F. per 100 ft. equivalent length

of tubing. When design conditions vary, the table values should be rechecked.

1. Liquid and suction lines based on a recommended equivalent pressure

drop of 2°F (3 psi for suction line, 6 psi for liquid line) per 100 ft. of

equivalent length.

4.

5.

2. When refrigerant required to charge a circuit exceeds the

pumpdown

capacity of that circuit the use of a separate refrigerant storage receiver

will be required. The pumpdown capacity (shown in Table 10) is based

on the condenser 90% full at 90°F.

3.

Wherever vertical rise occurs in the suction piping, the minimum tonnage

6.

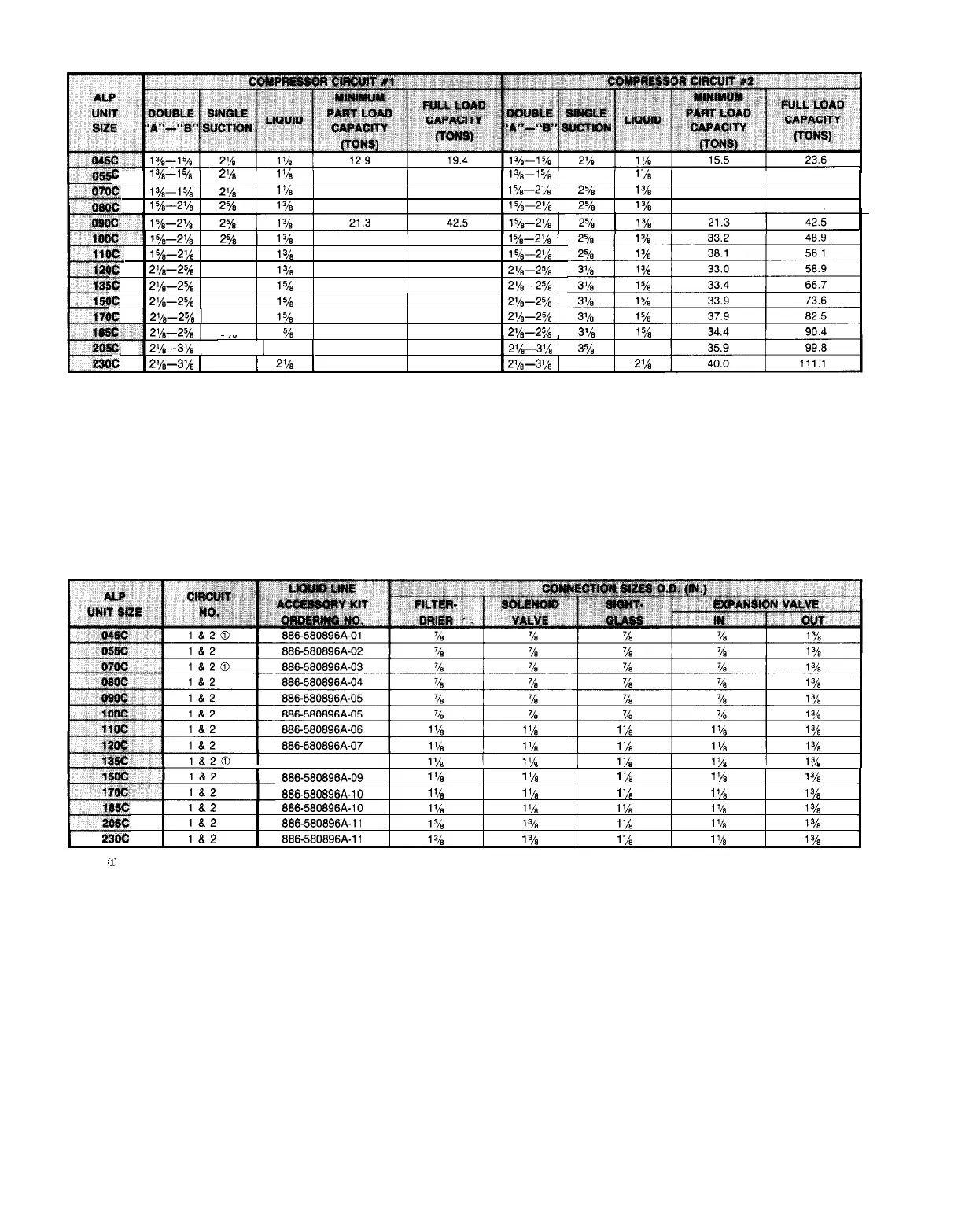

Table 8. Liquid line accessory kits (when supplied by McQuay)

Wherever vertical rise occurs in the suction piping on a system

with

hot

gas bypass, double suction risers may not be needed as the velocity of

suction gas is increased at minimum load conditions.

Total equivalent feet for a given piping layout must include the equivalent

length of straight pipe for fittings, valves and specialties added to the total

run of straight pipe.

Piping design,

sizing

and installation information presented in

ASHRAE

Handbooks should, where applicable, be followed in the design and In-

stallation of piping.

886-580896A-06

.” ,”

i

886~580896A-09 1%

1

‘/a

886~580896A-10

1

‘/s

1

‘/s

l&2

886-580896A-10

1%

l’/a

l&2

886-580896A-11

1%

1%

I

23oc

182

886~580896A-11

1%

1%

NOTE:

%

Larger capacity expansion valve in liquid line accessory kit is used for

circuit

#2.

,-

,_

._

1

‘/a

1

‘/a

1

Yi

1

‘h

1

‘/a

1%

1

‘h

1

‘/a

1%

1%

1

‘h

1%

t

‘/s

1

‘/a

1%

LIQUID LINE COMPONENTS

McQuay has available a “Liquid Line Accessory Kit” for each

ALP unit size. The kit does not include tubing. Table 8 shows

the ordering number to be used for each ALP unit size. The

components in these kits are:

1. Sealed core filter-driers (ALP-170 thru 230C have

replaceable core filter-driers).

2. Refrigerant solenoid valves.

3. Refrigerant

sightglass/moisture indicators.

4. Expansion valves (one per circuit).

HOLDING CHARGE

The Model ALP condensing unit is shipped with a holding

charge of refrigerant. At the time the unit was received a visual

inspection of the unit piping should have been made to be

sure no breakage had occurred or that fittings might have

been loosened. A pressure check should indicate a positive

pressure in the unit. If no pressure is evident, the unit will

have to be leak tested and the leak repaired. This should be

Page 8

/

IM 269

noted and reported to your McQuay sales representative or

freight carrier if the loss is due to shipping damage.

PRESSURE TESTING

No pressure testing is necessary unless damage was in-

curred during shipment or rigging. Damage may be deter-

mined by a visual inspection of the exterior piping assuming

no breakage has occurred or fittings have loosened. Pressure

gauges should show a positive pressure. If no pressure is

evident on the gauges, a leak has probably occurred releas-

ing all or part of the refrigerant charge. In this case, the unit

should be leak tested to locate the leak.

LEAK TESTING

In the case of loss of the refrigerant holding charge, the unit

should be checked for leaks prior to charging the complete

system. If the full charge was lost, leak testing can be done

by charging the refrigerant into the unit to build the pressure

Loading...

Loading...