IN-WARRANTY RETURN MATERIAL PROCEDURE

COMPRESSOR

Copeland

Refrigeration Corporation has stocking wholesalers

who maintain a stock of replacement compressors and ser-

vice parts to serve refrigeration contractors and servicemen.

When a compressor fails in warranty, contact your local

sales representative, or McQuay Warranty Claims Deparment

at the address on the cover of this bulletin. You will be

authorized to exchange the defective compressor at a

Copeland

wholesaler, or an advance replacement can be ob-

tained. A credit is issued you by the wholesaler for the re-

turned compressor after Copeland factory inspection of the

inoperative compressor. If that compressor is out of

Copeland’s warranty, a salvage credit only is allowed. Pro-

vide McQuay with full details; i.e., McQuay unit model and

unit serial numbers. Include the invoice and the salvage value

credit memo copies and we will reimburse the difference. In

this transaction, be certain that the compressor is definitely

defective. If a compressor is received from the field that tests

satisfactorily, a service charge plus a transportation charge

will be charged against its original credit value.

On all out-of-warranty compressor failures, Copeland of-

fers the same field facilities for service and/or replacement

as described above. The credit issued by Copeland on the

returned compressor will be determined by the repair charge

established for that particular unit.

COMPONENTS OTHER THAN COMPRESSORS

Material may not be returned except by permission of

authorized factory service personnel of McQuay Air Condi-

tioning at Minneapolis, Minnesota. A “return goods” tag will

be sent to be included with the returned material. Enter the

The return of the part does not constitute an order for

replacement. Therefore, a purchase order must be entered

through your nearest McQuay representative. The order

information as called for on the tag in order to expedite han-

dling at our factories and prompt issuance of credits.

should include part name, part number, model number and

serial number of the unit involved.

Following our personal inspection of the returned part, and

All parts shall be returned to the pre-designated McQuay

factory transportation charges prepaid.

if it is determined that the failure is due to faulty material or

workmanship, and in warranty, credit will be issued on

customer’s purchase order.

APPENDIX

STANDARD CONTROLS

NOTE: PERFORM AN OPERATIONAL CHECK ON ALL UNIT SAFETY CONTROLS ONCE PER YEAR.

OIL PRESSURESAFETY CONTROL

The oil pressure safety control is a manually resettable device

which senses the differential between oil pressure at the

discharge of the compressor oil pump and suction pressure

inside the compressor crankcase. When the oil pressure

reaches approximately 15 psi above the crankcase suction

pressure, the pressure actuated contact of the control opens

from its normally closed position. If this pressure differential

cannot be developed, the contact will remain closed and

energize a heater element within the control. The heater ele-

ment warms a normally closed bimetallic contact and causes

the contact to open, de-energizing a safety relay and break-

ing power to the compressor.

minutes for the heater element and bimetallic contacts to cool

and reset the control again.

It takes about 120 seconds to warm the heater element

enough to open the bimetallic contact, thus allowing time for

the pressure differential to develop.

If during operation, the differential drops below 10 psi, the

heater element will be energized and the compressor will

stop. The control can be reset by pushing the reset button

on the control. If the compressor does not restart, allow a few

To check the control, pump down and shut off all power

to the unit. Open the circuit breakers or the fused discon-

nect for that compressor and install a voltmeter between ter-

minals L and M of the oil pressure control. Turn on power

to the unit control circuit (separate disconnect or main unit

disconnect depending on the type of installation). Check to

see that the control stop switch

S1

is in the “on” position.

The control circuit should now be energized, but with the

absence of compressor power, no oil pressure differential can

develop and thus the pressure actuated contacts of the con-

trol will energize the heater element and open the bimetallic

contacts of the control within 120 seconds. When this hap-

pens, the safety relay is de-energized, the voltmeter reading

will rise to

24V,

and the compressor contactor should open.

Repeated operations of the control will cause a slight heat

buildup in the bimetallic contacts resulting in a slightly longer

time for reset with each successive operation.

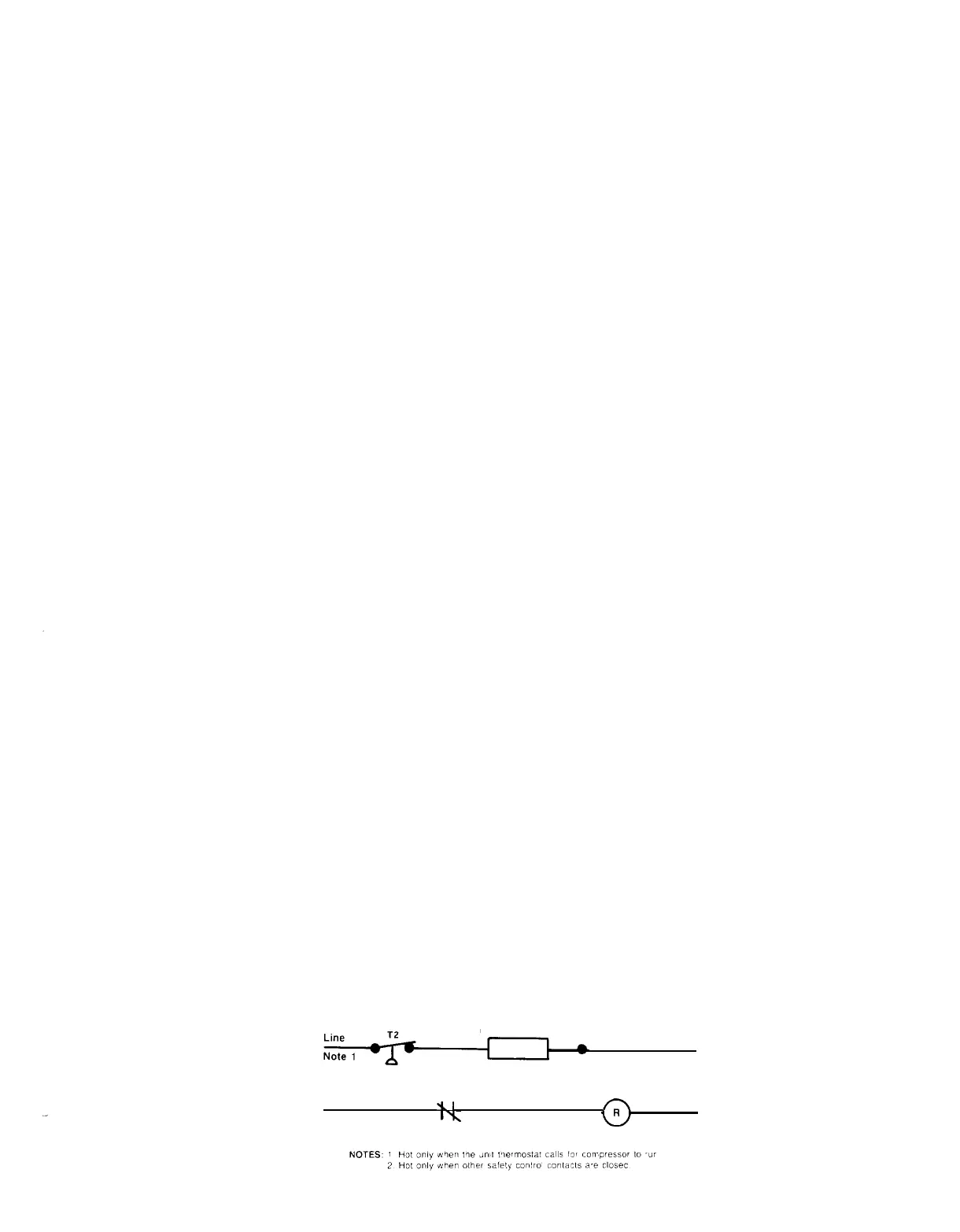

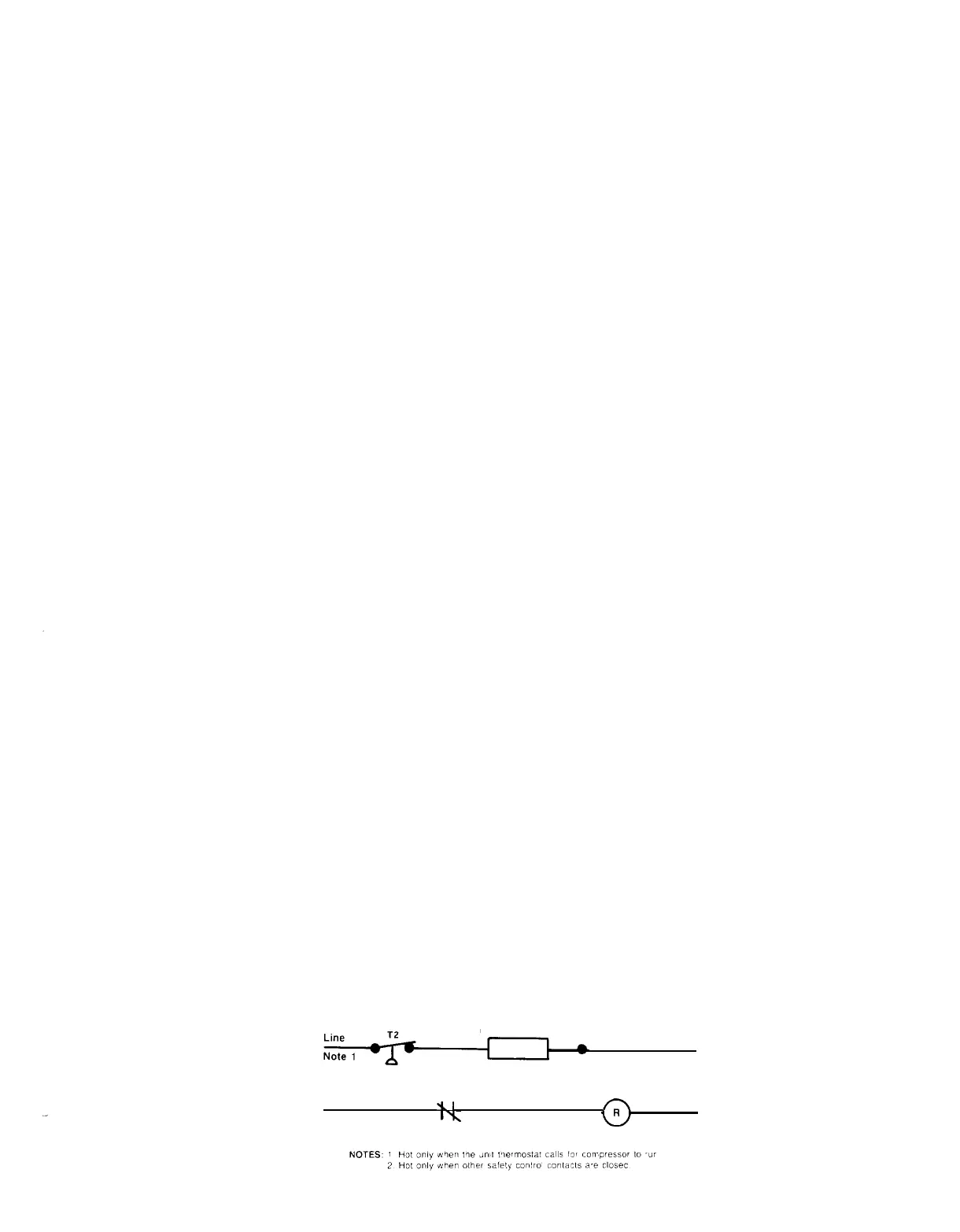

Pressure Actuator

Contact

Heater Element

Neutral

Line

Note 2

L M

*I

IX

Bimetallic Contacts

Neutral

Safety Relay

IM 269

/

Page 51

Loading...

Loading...