SERVICE

NOTE: Service on this equipment is to be performed by qualified refrigeration service per-

sonnel. Causes for repeated tripping of safety controls must be investigated and corrected.

CAUTION: Disconnect all power before doing any service inside the unit.

FILTER-DRIERS

To change the filter-drier, pump the unit down by moving

pumpdown

switches PS1 and PS2 to the “manual

pump-

down” position.

trol. Close the manual liquid line shutoff valve(s). Turn power

to the unit back on and restart the unit by moving the control

switch

S1

to the “on” position. The unit will start pumping

down past the low pressure setting. When the evaporator

pressure reaches O-5 psig, move control switch

S1

to the

“off” position.

Move the control switch

S1

to the “off” position. Turn off all

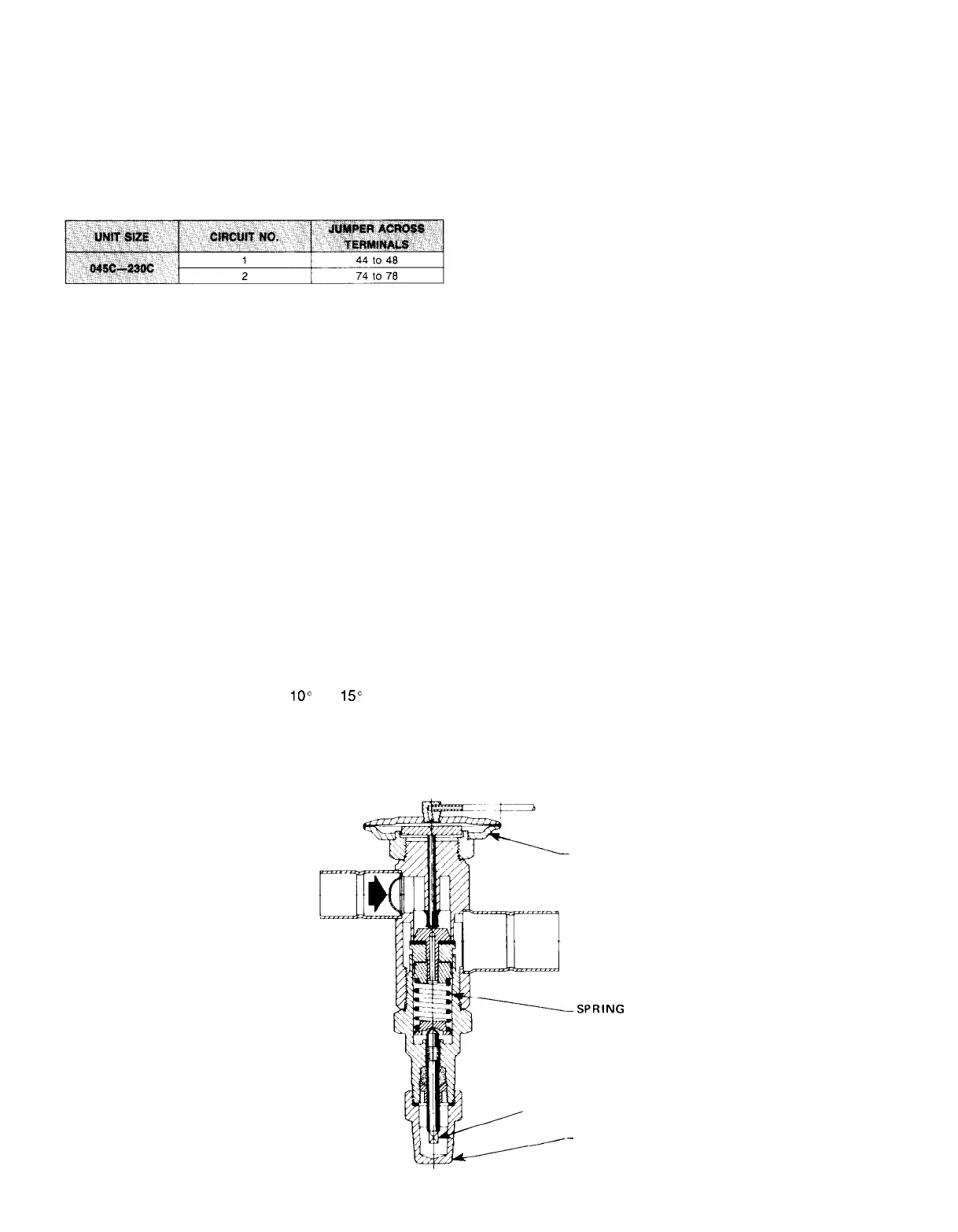

power to the unit and install jumpers across the terminals

shown in the table. This will jump out the low pressure

con-

Frontseat the suction line King valve(s). Remove and

replace the filter-drier(s). Evacuate the lines through the

li-

quid line manual shutoff valve(s) to remove non-condensables

that may have entered during filter replacement. A leak check

is recommended before returning the unit to operation.

LIQUID LINE SOLENOID VALVE

The liquid line solenoid valves, which are responsible for

automatic

pumpdown

during normal unit operation, do not

normally require any maintenance. They may, however, re-

quire replacement of the solenoid coil or of the entire valve

assembly.

The solenoid coil may be removed from the valve body

without opening the refrigerant piping by moving

pumpdown

switches PS1 and PS2 to the “manual pumpdown” position.

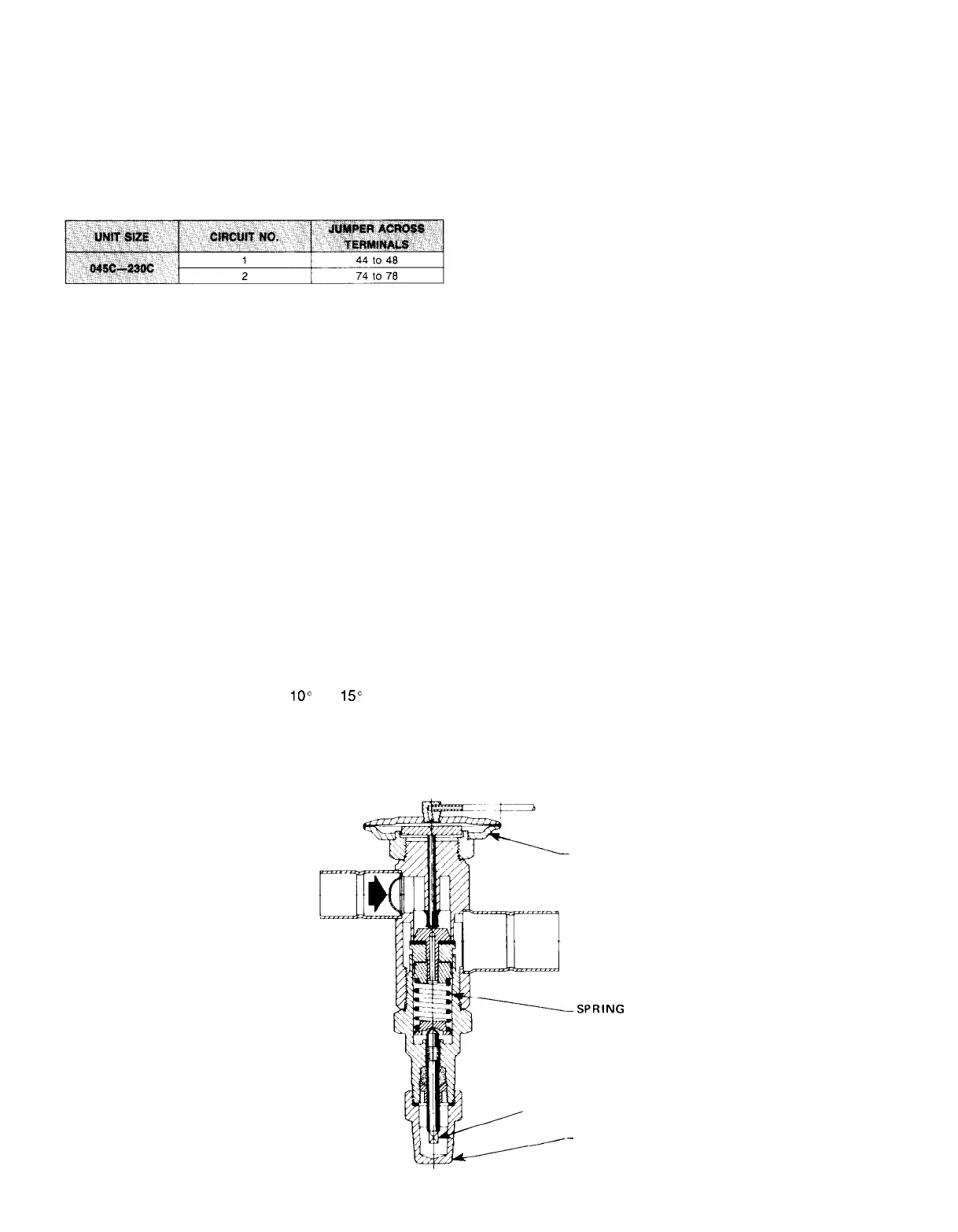

THERMOSTATICEXPANSION VALVE

The expansion valve is responsible for allowing the proper

amount of refrigerant to enter the evaporator regardless of

cooling load. It does this by maintaining a constant superheat.

(Superheat is the difference between refrigerant temperature

as it leaves the evaporator and the saturation temperature

corresponding to the evaporator pressure.) Typically,

superheat should run in the range of 10” F to 15” F. On valves

purchased through McQuay, the superheat setting can be

adjusted by removing the cap at the bottom of the valve to

expose the adjustment screw. Turn the screw clockwise

(when viewed from the adjustment screw end) to increase

the superheat setting and counterclockwise

superheat. Allow time for system rebalance

superheat adjustment.

The expansion valve, like the solenoid valve,

should not

normally require replacement, but if it does, the unit must

be pumped down by following the steps involved when chang-

ing a filter-drier.

If the problem can be traced to the power element only,

it can be unscrewed from the valve body without removing

the valve, but only after pumping the unit down.

INLET

The coil can then be removed from the valve body by simply

removing a nut or snap-ring located at the top of the coil. The

coil can then be slipped off its mounting stud for replacement.

Be sure to replace the coil on its mounting stud before retur-

ning

pumpdown

switches

PS1

and PS2 to the “auto

pump-

down” position.

To replace the entire solenoid valve follow the steps in-

volved when changing a filter-drier.

to reduce

after each

POWER ELEMENT

(CONTAINS DIAPHRAGM)

OUTLET

ADJUSTMENT SCREW

/-

CAP

Page 50 I IM 269

Loading...

Loading...