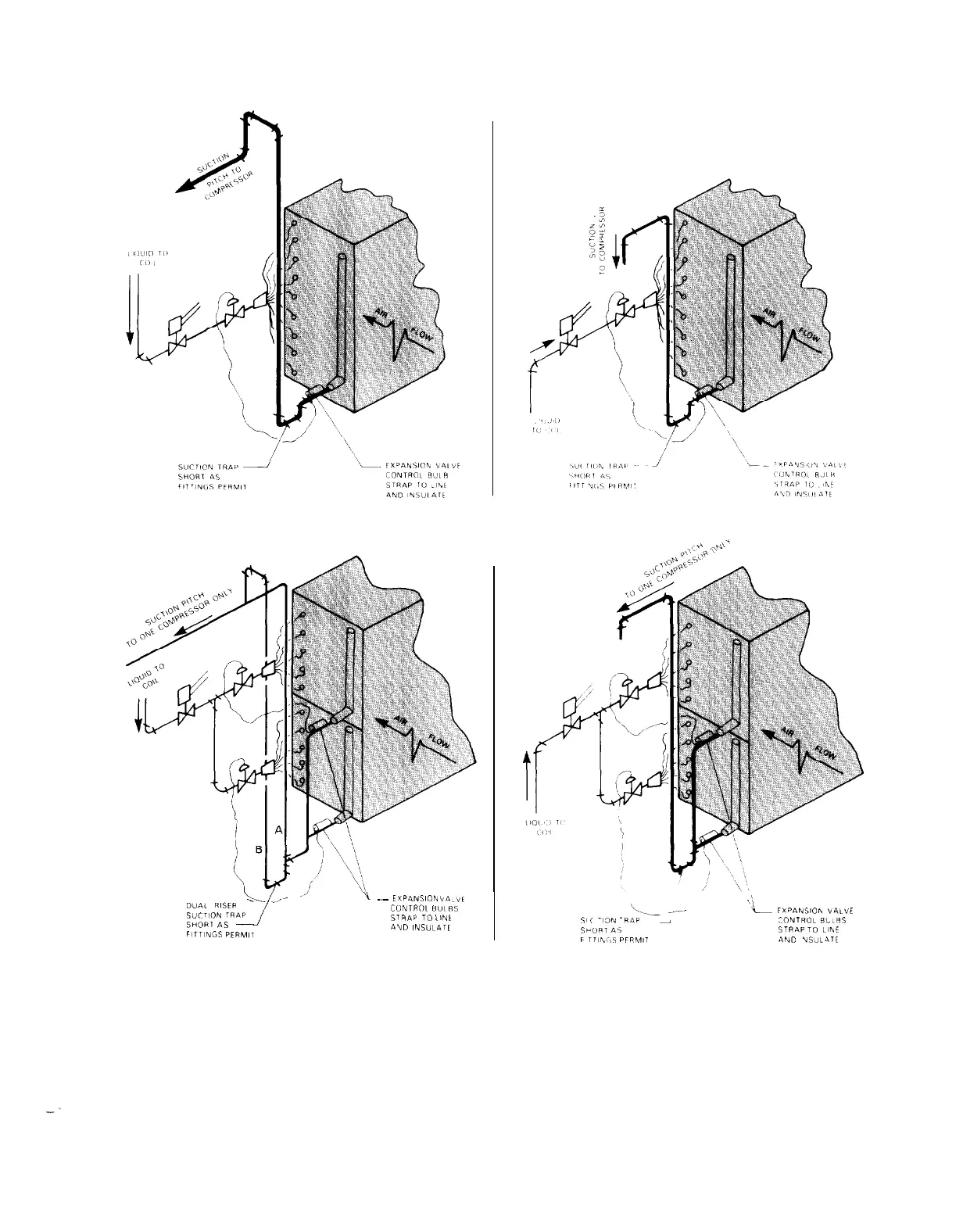

Figure 6. SINGLE CIRCUIT EVAPORATOR

-

RECOMMENDED PIPING

If Row Split Coils Are Used, Duplicate The Piping

CONDENSING UNIT ABOVE THE EVAPORATOR

CONDENSING UNIT BELOW THE EVAPORATOR

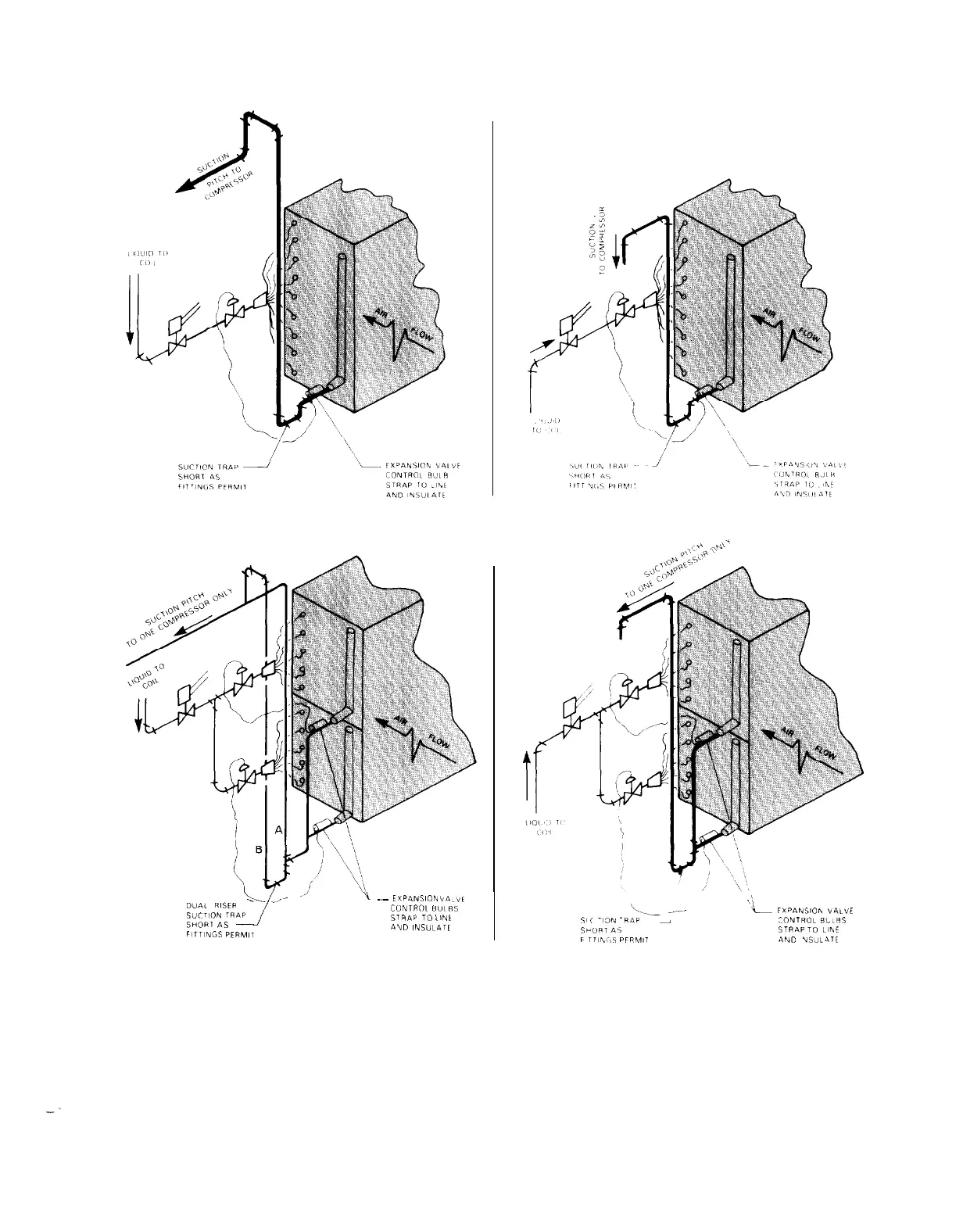

Figure 7. DUAL CIRCUIT EVAPORATOR (FACE SPLIT)

-

RECOMMENDED PIPING

_d”

\

_,

D”Ai

RISER

L

-.-

1

~~

iVP4NSlON

Lla.,vt

;:

CONTROL

BULBS

SUCTION

TRAP

L

FXPANSlOlv

VALVE

‘S~FIPIV

TO

LlNt

\.__

_--

SHORT

AS

$1

!

-,m

.R‘iP

-

TONTROL BLLRS

--

i’

“IUD

INSULnrE

FITTINGS

PERMIT

SMORT

*s

STRAP

TO

LlhE

F

TT,rvi,S

PFPMll

4ND

US”L4TE

NOTES:

1.

Piping shown is for one compressor circuit; second circuit is similar. Must have separate piping for each compressor circuit.

2.

Trap for double suction riser should be as small in horizontal direction as fittings will allow.

3.

The thermal expansion valve equalizer line should be placed just past the thermal sensing bulb on the side or top of the pipe.

4. A separate expansion valve is required for each distributor and mounted per manufacturer’s recommendations.

(See additional notes under recommended line sizes, Table 7.)

REFRIGERANT PIPING CONNECTIONS

Refrigerant piping connections will be made at the

com-

unit. When piping, allow room for the unit disconnect and field

pressor end of the unit. Suction and liquid lines should be

wiring to the unit. Figures 8 and 9 show piping connections

routed through the compressor enclosure on each side of the

and sizes for each ALP model.

IM 269

/ Page 7

Loading...

Loading...