PHASE/VOLTAGE MONITOR (OPTIONAL)

tection

against three-phase electrical motor

loss due

to power

failure conditions, phase loss, and phase reversal. Whenever

any of these conditions occur, an output relay is deactivated,

disconnecting power to the thermostatic control circuit,

automatically pumping down the unit.

The phase/voltage monitor is a device which provides

pro-

put relav does not close. oerform the followina tests.

i.

2.

Check the voltages between Ll-L2,

L1-L3-and

L2-L3.

These voltages should be approximately equal and within

+ 10% of the rated three-phase line-to-line voltage.

If these voltages are extremely low or widely unbalanced

check the power system to determine the cause of the

problem.

The output relay remains deactivated until power line con-

ditions return to an acceptable level. Trip and reset delays

have been provided to prevent nuisance tripping due to rapid

power fluctuations.

3.

When three-phase power has been applied, the output relay

should close and the “run light” should come on. If the

out-

If the voltages are good, turn off the power and interchange

any two of the supply power leads at the disconnect.

This may be necessary as the phase/voltage monitor

is sensitive to phase reversal. Turn on the power. The out-

put relay should now close after the appropriate delay.

HOT GAS BYPASS (OPTIONAL)

Hot gas bypass is a system for maintaining evaporator

pressure at or above a minimum value. The purpose for do-

ing this is to keep the velocity of the refrigerant as it passes

through the evaporator high enough for proper oil return to

the compressor when cooling load conditions are light. It also

maintains continuous operation of the chiller at light load con-

ditions. Hot gas bypass kits are described on page 9.

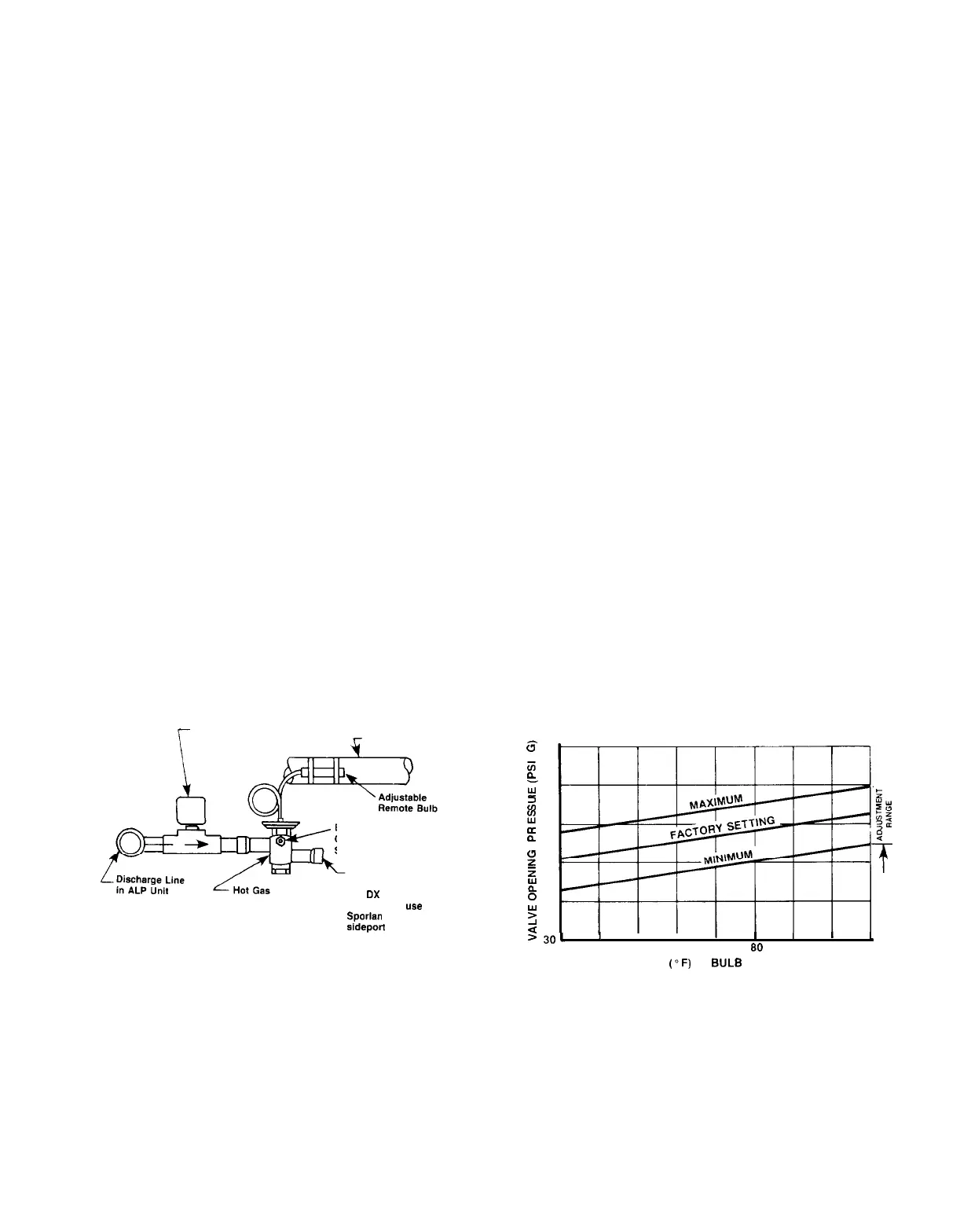

The solenoid valve should be wired to open whenever the

unit thermostat calls for the first stage of cooling (see Figures

10 thru 12). The pressure regulating valve that

McQuay of-

fers is factory set to begin opening at 58 psig (32F for R-22)

when the air charged bulb is in an 80F ambient temperature.

The bulb can be mounted anywhere as long as it senses a

fairly constant temperature at various load conditions. The

compressor suction line is one such mounting location. It is

generally in the 50F to 60F range. The chart below indicates

that when the bulb is sensing 50F to 60F temperatures, the

valve will begin opening at 54 to 56 psig. This setting can

be changed as indicated above, by changing the pressure

of the air charge in the adjustable bulb. To raise the pressure

setting, remove the cap on the bulb and turn the adjustment

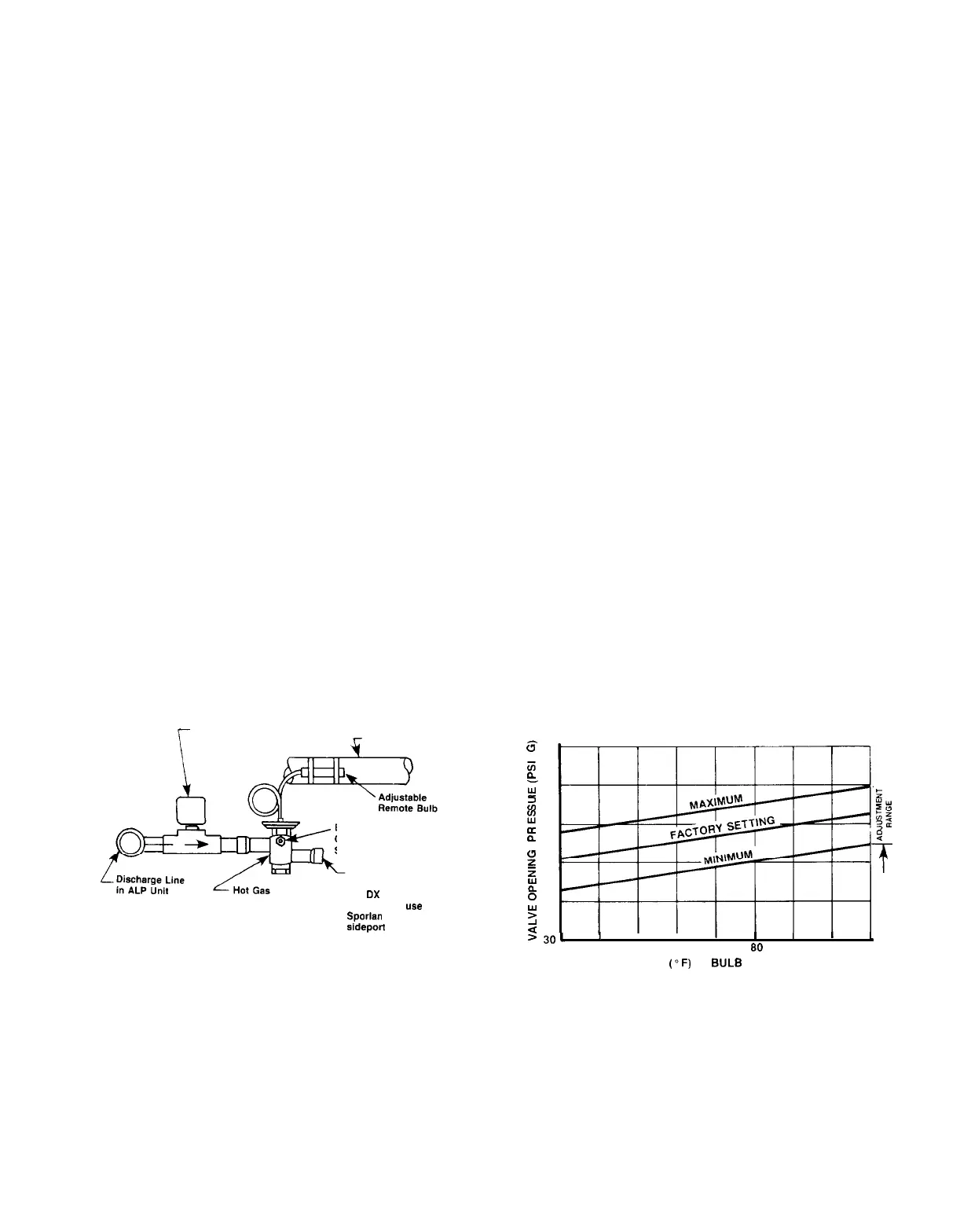

Hot Gas Bypass Piping Diagram

Hot Gas Bypass

Solenoid Valve

4

Suction Line

External Equalizer

Connection to Suction

Side of Evaporator

To Evaporator Inlet

After Expansion Valve

Bypass Valve

(On

OX

coils with

distributors,

use

Sporlan auxiliary

sideport connector

or equivalent)

screw clockwise. To lower the setting, turn the screw

counterclockwise. Do not force the adjustment beyond the

range it is designed for, as this will damage the adjustment

assembly.

The regulating valve opening point can be determined by

slowly reducing the system load (or increasing the required

chilled water temperature setting indicated on the unit ther-

mostat), while observing the suction pressure. When the

bypass valve starts to open, the refrigerant line on the

evaporator side of the valve will begin to feel warm to the

touch.

CAUTION: The hot gas line may become hot enough

to

cause

injury in a very short time, so care should be taken during

valve checkout.

On installations where the condensing unit is remote from

the evaporator, it is recommended that the hot gas bypass

valve be mounted near the condensing uni! to minimize the

amount of refrigerant that will condense in the hot gas line

during periods when hot gas bypass is not required.

Hot Gas Bypass Adjustment Range

REMOTE BULB ADJUSTMENT RANGE

6

80

z

P

$

70

4

z

2

Jg

z

60

Z$

?a

E

2

P

50

z

f

2

O

2

40

ti

>

301

I

I I

I

I

I

30

40 50 60 70

SO

90 100 110

TEMP.

(OF)

AT

BULB

LOCATION

IM 269

/

Page 55

Loading...

Loading...