APPENDIX

OPTIONAL CONTROLS

SPEEDTROL HEAD PRESSURE CONTROL (OPTIONAL)

The SPEEDTROL system of head pressure control operates

partments. Units with 460 volt power have a transformer

in conjunction with FANTROL by modulating the motor speed

mounted inside the condenser fan 21 fan compartment to step

on fans 11 and 21 in response to condensing temperature.

the voltage down to 230 volts for the SPEEDTROL motors.

By reducing the speed of the last fan as the condensing

The SPEEDTROL control starts to modulate the motor

pressure falls, the unit can operate at lower ambient

speed at approximately 105°F and maintains a minimum

con-

temperatures.

densing pressure of 170 to 180 psig.

The SPEEDTROL fan motor is a single phase, 2081240 volt,

The SPEEDTROL sensors are clipped to a return bend on

thermally protected motor specially designed for variable

the bottom row of the condenser coil. SPEEDTROL controls

speed application. The solid-state speed controls SC1 1 and

and SPEEDTROL transformer are shown in Figures 21 and

SC21 are mounted inside condenser fan 11 and 21 fan

com-

23.

COMPRESSOR UNLOADERS (OPTIONAL)

UNLOADERS CONTROLLED FROM SUCTION PRESSURE:

With a decrease in load, the suction pressure drops, pressure

solenoid

U1

which increases the compressor capacity.

control PC8 closes, energizing unloader solenoid

U1.

This

closes the suction port to one cylinder bank and reduces the

PC8,

cut-in: 64 psig; cut-out: 72 psig

compressor capacity. Compressor circuit 2 operates the same

PC9,

cut-in: 64 psig; cut-out: 72 psig

way.

The cut-in and cut-out pressures can be adjusted to meet field

With an increase in the load, the suction pressure

in-

combinations. If the unloader cycles excessively, the

differen-

creases, pressure control PC8 opens, de-energizing unloader

tial between cut-in and cut-out should be increased.

LOW AMBIENT START (OPTIONAL)

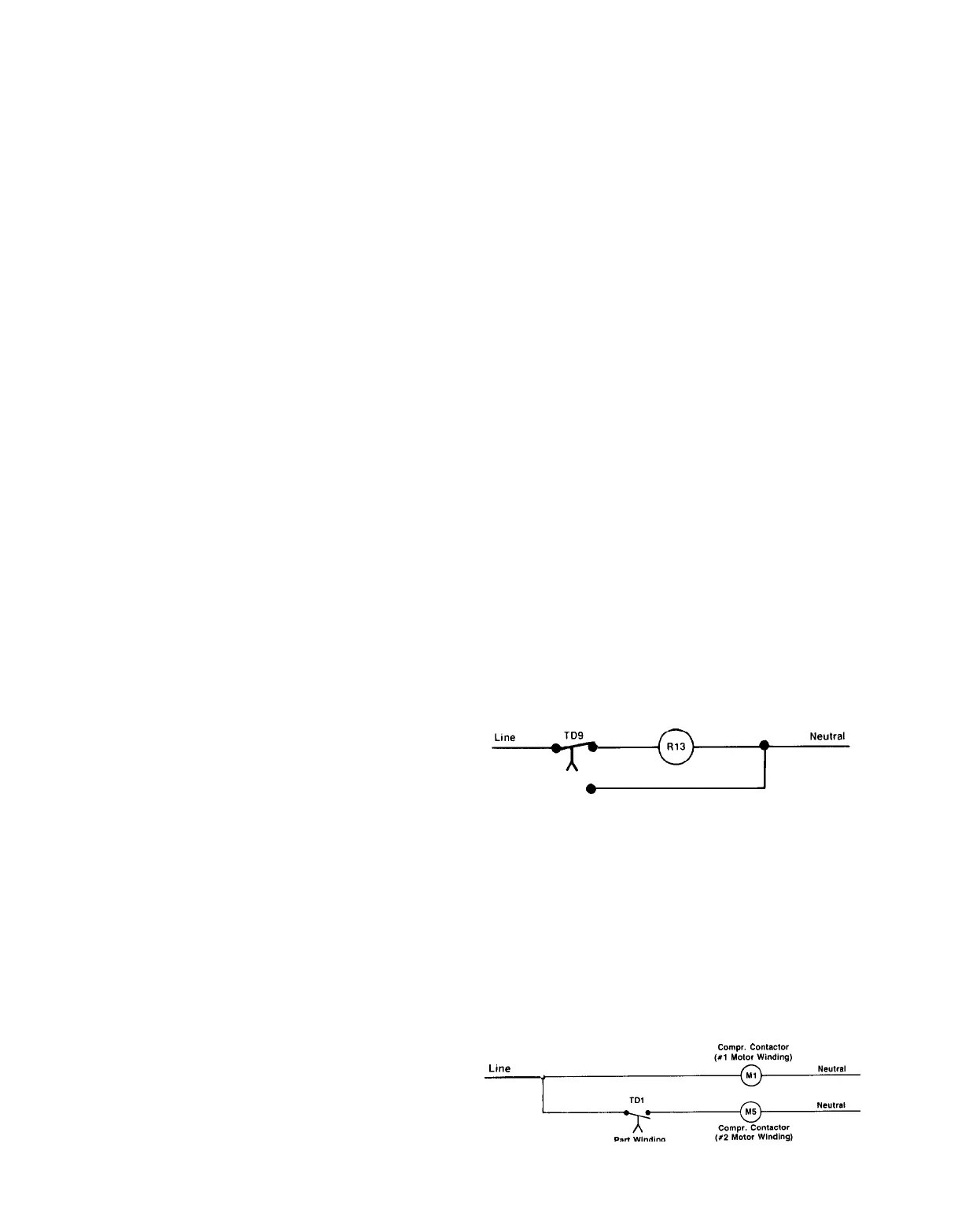

Low ambient start is available on all units as an option with

FANTROL and included automatically with optional

SPEED-

TROL. It consists of a solid-state, normally closed time delay

wired in series with a relay. These are both wired in parallel

to the liquid line solenoid valve so that when the solenoid

valve is energized by the unit thermostat the low ambient start

relay is also energized through the time delay. The relay has

contacts that essentially short-circuit the low pressure

con-

trol and freezestat and allow the compressor to start with the

low pressure control open.

After about 2% minutes, the time delay will open and

de-

To check the control, turn off all power to the unit and

remove the wire(s) leading to the terminals of the low pressure

control(s)

LPl

and LP2. Remove power to the compressor

and jumper across terminals 48 to 50 for circuit 1 and 78 to

80 for circuit 2. Switch the

pumpdown

switch(es)

PS1

and

PS2 to the “auto pumpdown” position. Energize the control

circuit by turning on the control circuit disconnect or main

power disconnect (depending on the installation) and the con-

trol stop switch

S1

The compressor contactors should pull

in instantly and trip back out after the 2% minute time delay.

energize the relay. If the system has not built up enough

evaporator pressure to close the low pressure control, the

compressor will stop. The time delay can be reset to its

original normally closed position by moving the

pumpdown

switch(es)

PS1

or PS2 to the “manual pumpdown” position.

Moving the

pumpdown

switch back to the “auto pumpdown”

position will again energize the relay for another attempt at

startup. If the system has built up enough evaporator pres-

sure, the compressor will continue to run.

Low Ambient

Low Ambient

Start

Time

Delay

start Relay

0

NOTE: Line is only hot when the unit thermostat calls for compressor to run.

HIGH AMBIENT (OPTIONAL)

The high ambient control is a single pole pressure activated

switch that closes on a pressure rise to partially unload one

or both circuits. It senses condenser pressure and is factory

set to close at 375 psig and will automatically reset at 300

psig. To check the control, either block off condenser sur-

face or start the unit with fuses in only one condenser fan

fuse block (FB6) and observe the cut-in point of the control

by monitoring when the compressor unloads. The purpose

of the control is to allow the unit to continue operating when

the ambient temperature exceeds the design temperature of

the unit. High ambient sensor locations are shown in Figures

20 and 22.

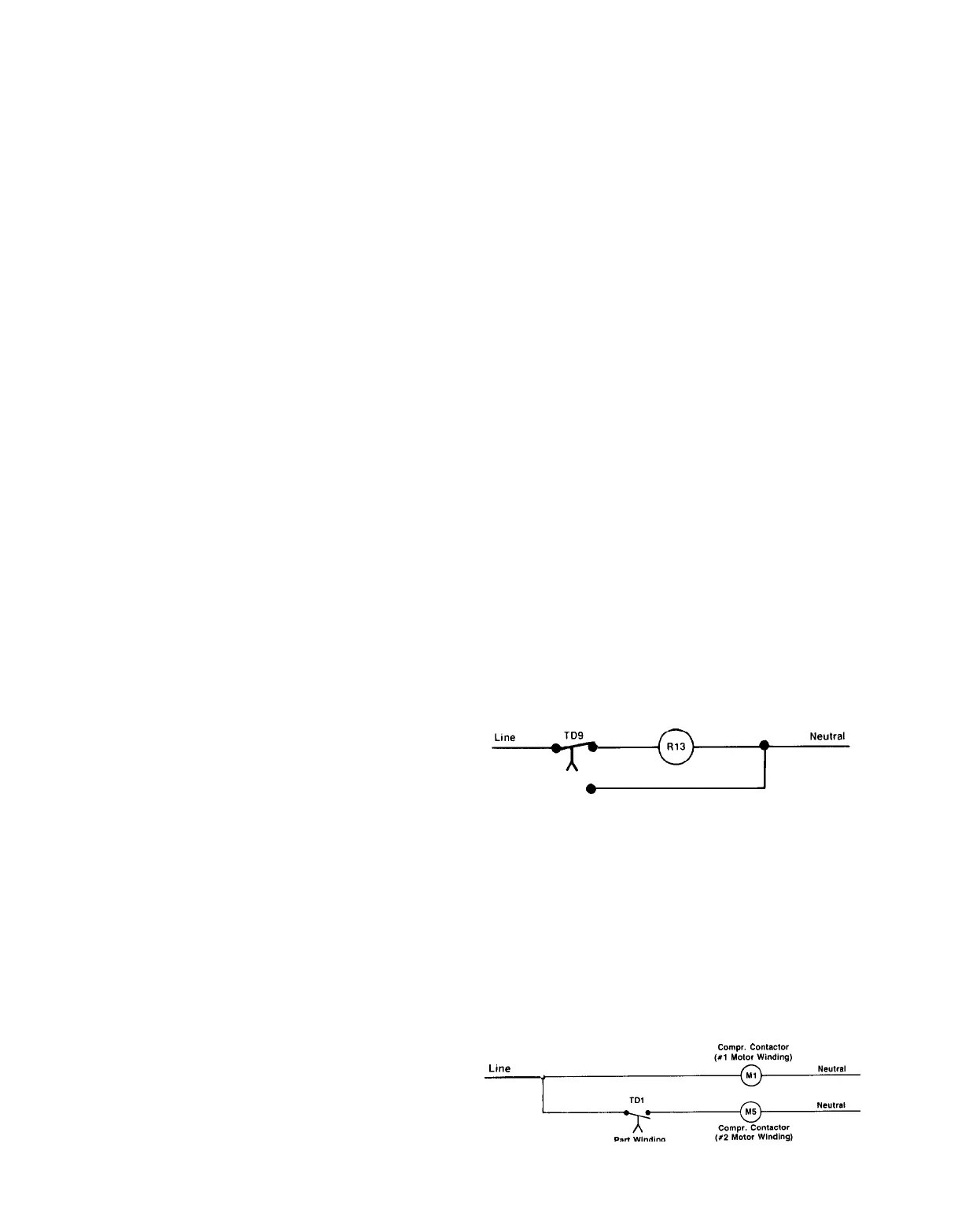

PART WINDING START (OPTIONAL)

Part winding start is available on all voltage units and con-

sists of a solid-state time delay wired in series with the

con-

tactor that energizes the second winding of each compressor

motor. Its purpose is to limit current in-rush to the com-

pressors upon startup. As each compressor starts, the

con-

tactor of the first motor winding is delayed for 1 second.

Control checkout is best accomplished by observation as

each contactor is pulled in to see that the 1 second delay

occurs before the second contactor pulls in.

Page 54 / IM 269

-

Line

I?--

Part

Winding

Time Delay

Loading...

Loading...