HIGH PRESSURE CONTROL

The high pressure control is a single pole pressure activated

trol on a high pressure gauge.

switch that closes on a pressure rise. When the switch closes,

The control is attached to a Shrader fitting and is located

R1

is energized which in turn de-energizes the control cir-

on a cylinder head near the discharge King valve. CAUTION:

cuit,

shutting down the compressor circuit. R1 also locks itself

Although there is an additional pressure relief device in the

in a manually resettable holding circuit through

RS1.

The

system set at 450 psig, it is highly recommended

that

the

switch is factory set to close at 400 psig and open at 300 psig.

“control stop” switch

S1

be close

at

hand in case the high

To check the control, either block off condenser surface pressure control should malfunction.

or start the unit with condenser fan motor fuses in only one

After testing the high pressure control, check the pressure

fan fuse block (FB6) and observe the cutout point of the

con-

relief device (on the condenser header) for leaks.

LOW PRESSURE CONTROL

The low pressure control is a single pole pressure switch that lowest evaporator pressure reached before cutout is the

closes on a pressure rise. It senses evaporator pressure and

cutout setting of the control. Wait for the compressor lockout

is factory set to close at 60 psig and automatically open at

time delays

TD1

and TD2 to time out. By moving the

pump-

25 psig. The control has an adjustable range of 20 inches down

switch(es)

PSI and PS2 to the “auto pumpdown”

posi-

of Hg. to 100 psig and an adjustable differential of 6 to 40 tion, evaporator pressure will rise. The highest evaporator

psig. To check the control (unit must be running), move the

pressure reached before compressor restart is the cut-in

set-

pumpdown

switch(es)

PS1

and PS2 to the “manual

pump-

ting of the control.

down” position. As the compressor pumps down, condenser

The control is attached to a Shrader fitting and is located

pressure will rise and evaporator pressure will drop. The below the suction King valve body.

FANTROL HEAD PRESSURE CONTROL

FANTROL is a method of head pressure control which

automatically cycles the condenser fans in response to

con-

denser pressure and ambient air temperature. This maintains

head pressure and allows the unit to run at low ambient air

temperatures.

All ALP units have dual independent circuits with the fans

for circuit 1 and circuit 2 being controlled independently by

the condensing pressure and ambient air of each circuit. Fans

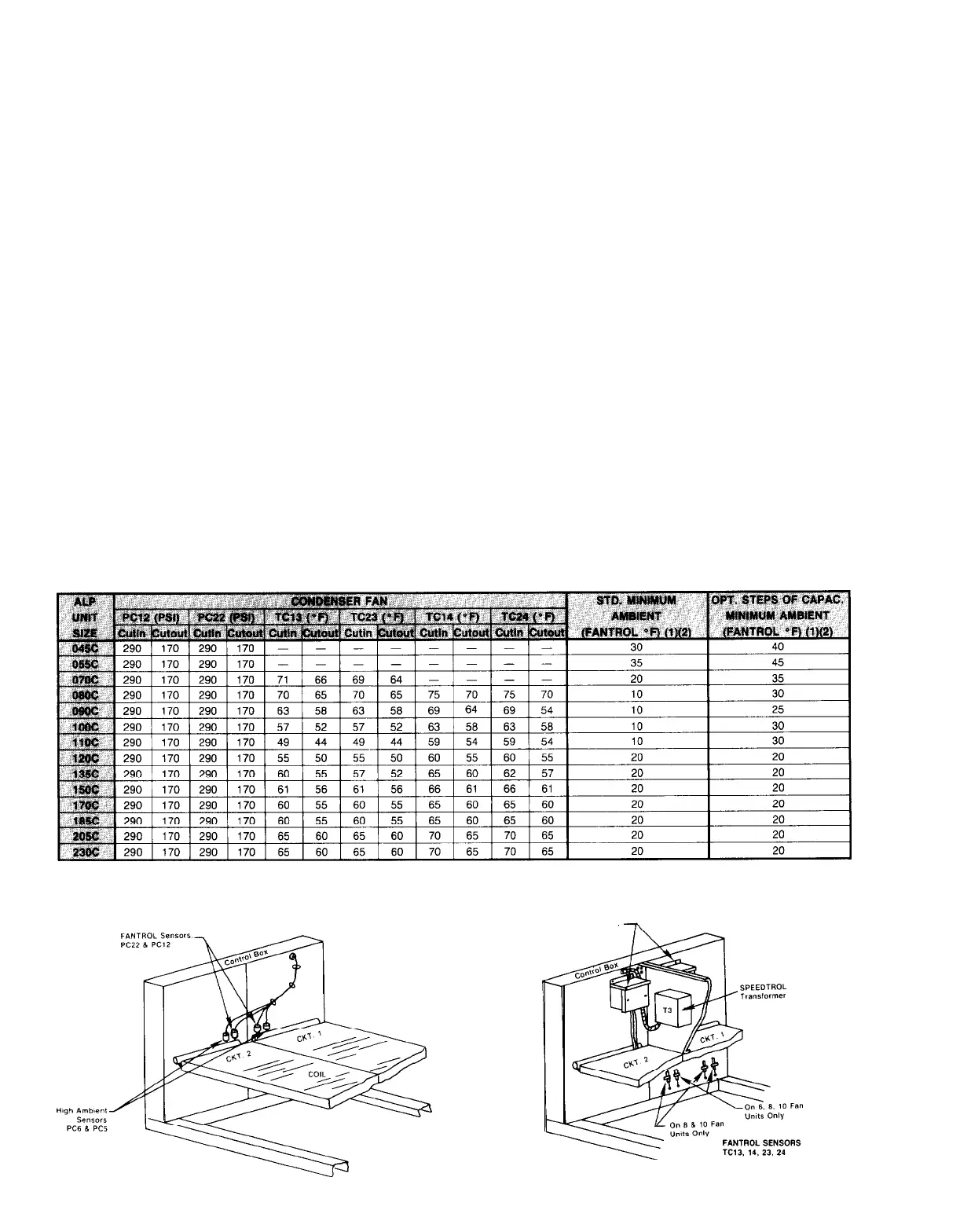

Table 23. Factory FANTROL Settings

11 and 21 start with each compressor and fans 12 and 22

cycle on and off in response to condenser pressure. The

cut-

out and cut-in pressures are given in Table 23. Fans 13 and

14 (circuit 1) and fans 23 and 24 (circuit 2) are

con-

trolled by ambient temperature and are factory set at the

values given in Table 23. Note that the number of fans on

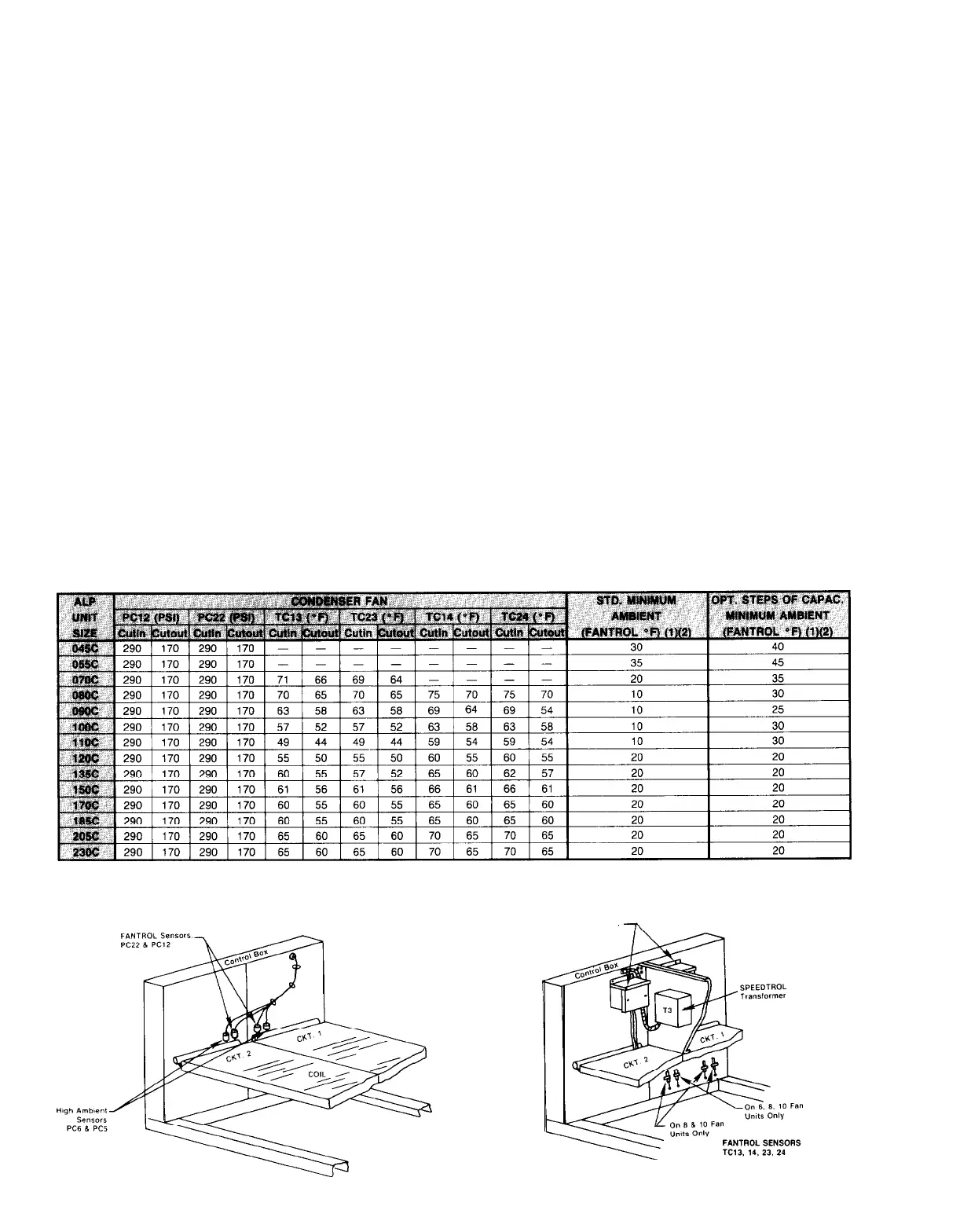

each unit varies. FANTROL sensor locations are shown in

Figures 20 thru 23.

NOTES:

(1) With SPEEDTROL, all units minimum ambient operating temperature drops to 0°F.

(2) Minimum head pressure on partly loaded compressor

is

110 psig; on full load it

is

170

psig.

Figure 20.

Figure 21.

SPEEDTROL

Controls

Page 52

/

IM 269

Loading...

Loading...