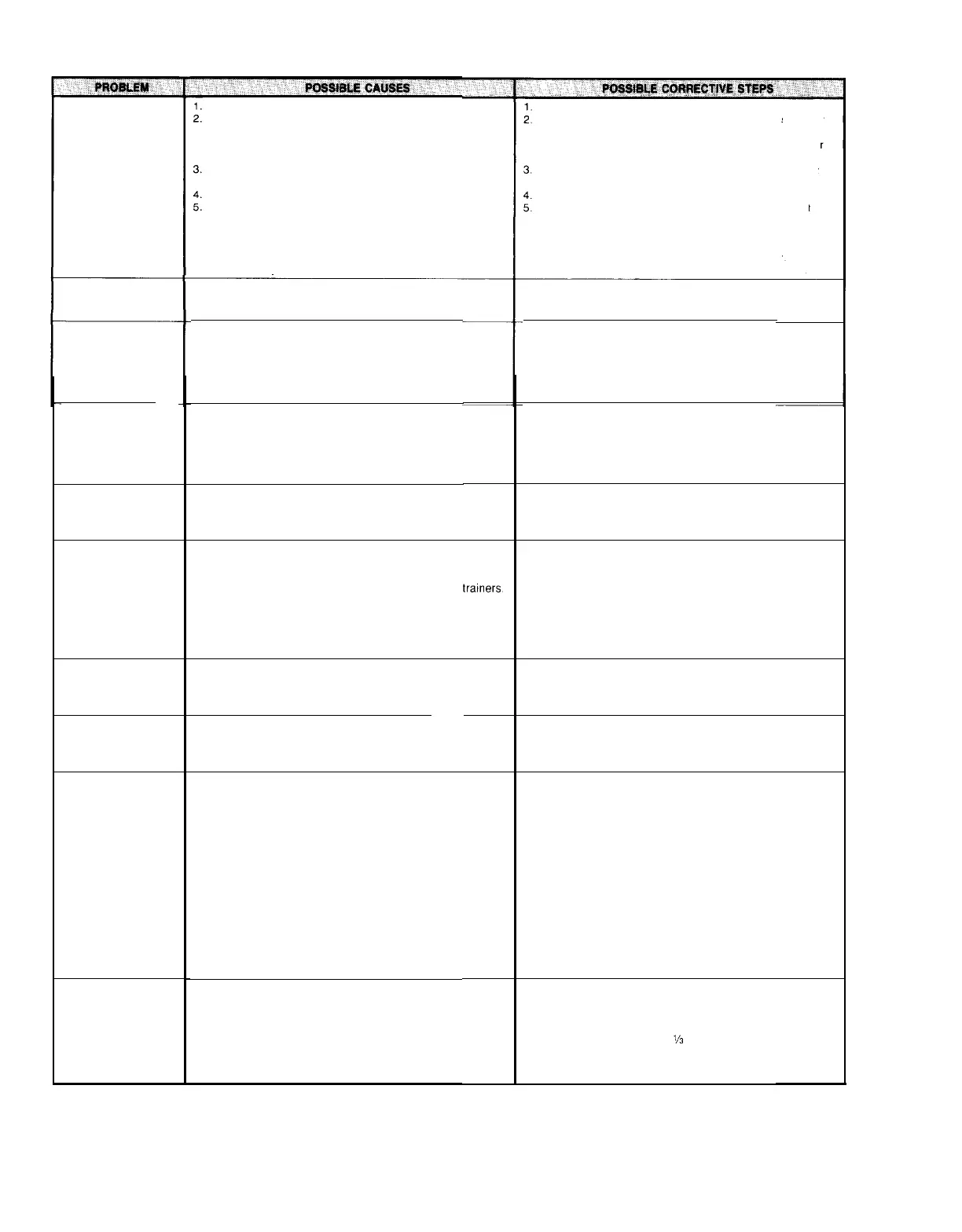

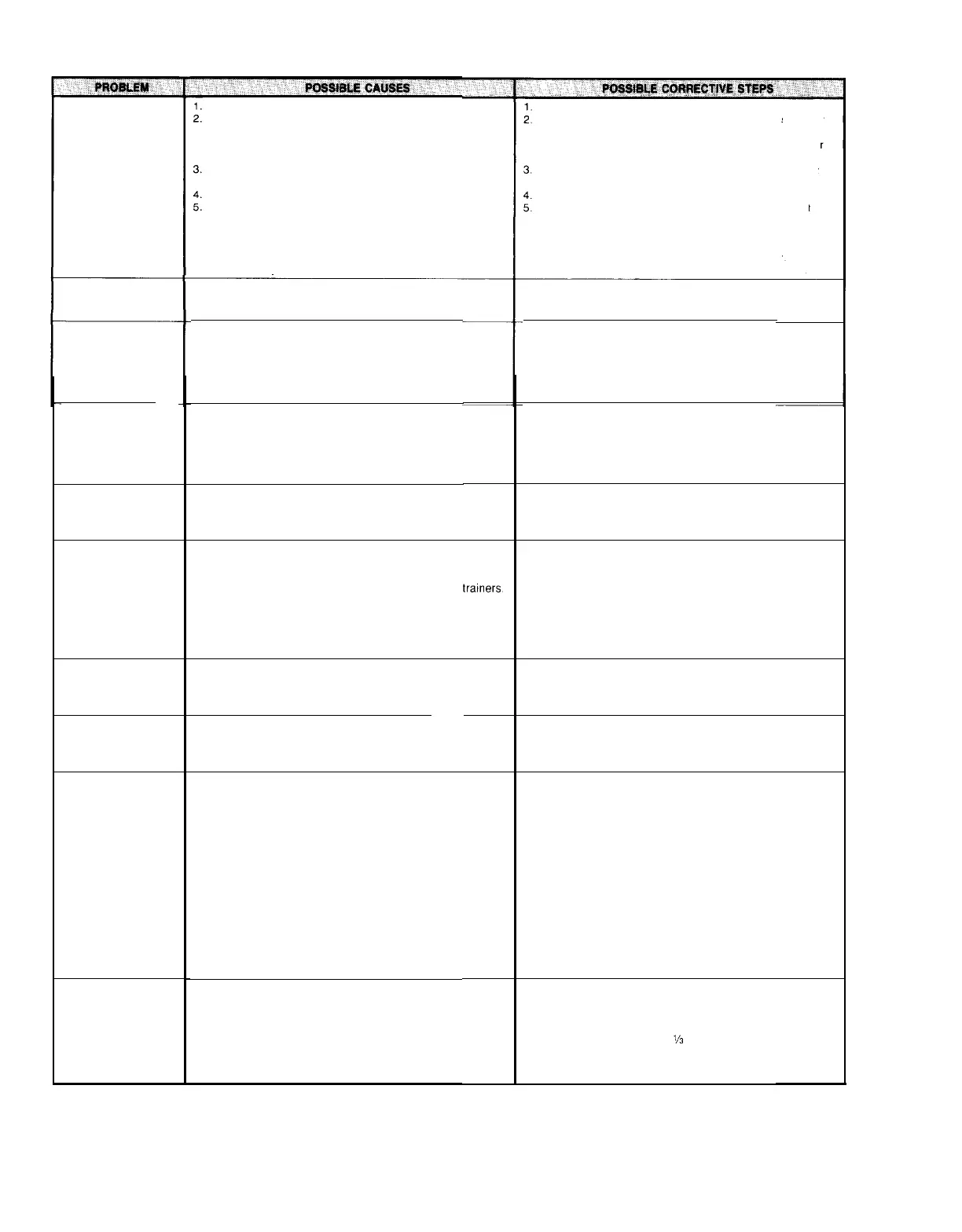

TROUBLESHOOTING CHART

COMPRESSOR WILL

NOT RUN

COMPRESSOR

NOISY

OR VIBRATING

HIGH DISCHARGE

PRESSURE

LOW DISCHARGE

PRESSURE

HIGH SUCTION

PRESSURE

LOW SUCTION

PRESSURE

COMPRESSOR WILL

WILL NOT UNLOAD

OR LOAD

COMPRESSOR

LOADING/UNLOADING

INTERVALS

TOO SHORT

LOSS OF OIL

PRESSURE OR

NUISANCE OIL

PRESSURECONTROL

TRIPS

COMPRESSOR

LOSES OIL

6.

7.

6.

9.

Main switch open.

Fuse blown. Circuit breakers open.

Thermal overloads tripped.

Defectve

contactor or coil.

System shut down by safety

devices

No cooling required.

Liquid line solenoid will not open.

Motor electrical trouble.

Loose wiring

1.

Flooding

of refrigerant into crankcase

2. Improper

piping

support on suction or

liquid

line

3. Worn compressor.

1. Noncondensables in system.

2. System overcharged with refrigerant.

3. Discharge shutoff valve partially closed.

4. Fan not

running.

5. Dirty condenser

coil

6. FANTROL out of adjustment.

1. Check

setting

of

expansion

valve.

2.

Relocate, add or remove hangers

3.

Replace.

1.

Purge the noncondensables.

2.

Remove excess.

3.

Open valve.

4. Check electrical circuit.

5.

Clean coil.

6.

Adjust

FANTROL settinqs.

1.

Faulty condenser temperature regulation.

2. Suction shutoff valve partially closed

3. Insufficient refrigerant in system.

4. Low suction pressure.

5. Compressor operating unloaded

1.

Check condenser control operation.

2. Open valve.

3. Check for leaks.

Rapair

and add charge.

4. See Corrective Steps for low suction pressure

5. See Corrective Steps for failure of compressor

below.

1.

Excessive load.

1. Reduce load or add

additional

equipment.

2. Expansion valve

overfeeding.

2. Check remote bulb. Regulate superheat.

3. Compressor unloaders open

3. See

Corrective

Steps below for failure of

comp

1. Lack of

refrigerant

2. Evaporator dirty.

3. Clogged liquid line filter-drier

4. Clogged suction line or compressor suction gas s

5. Expansion valve

malfunctioning.

6. Condensing temperature too low.

7. Compressor will not load.

8. Insufficient

air

or water flow. 8. Adjust

airflow

or water

gpm.

1. Defective capacity control.

1

Replace.

2. Unloader mechanism defective.

2.

Replace.

3. Faulty thermostat stage or broken capillary tube.

3.

Replace.

4. Staaes not set for application. 4. Reset thermostat setting to fit

application.

1.

Erratic water thermostat.

1

Replace.

2. Insufficient water flow

2

Adjust

gpm

1. Clogged suction oil strainer

2. Excessive

liquid

in crankcase.

3. Oil pressure gauge defective

6. Oil pump reversing gear stuck

in

wrong position.

4. Low oil pressure safety switch defective.

5. Worn oil pump.

7. Worn bearings.

8. Low oil level.

6 Reverse direction of compressor rotation.

7. Replace compressor.

3 Repair or replace. Keep valve closed except

w

6. Add

oil.

readings.

4 Replace.

5. Replace

9. Loose fitting on oil lines.

10. Pump housing gasket leaks.

11.

Flooding of refrigerant into crankcase.

12. Iced up evaporator coil.

13. Insufficient air or water flow.

9. Check and

tighten

system.

10. Replace gasket.

11.

Adjust thermal expansion valve.

12 Clean coil.

13. Adjust air flow or water qpm.

1.

Lack of refrigerant.

1. Check for leaks and repair Add refrigerant.

2. Excessive compression ring blow-by

2. Replace compressor.

3. Suction superheat too high 3. Adjust superheat.

4. Crankcase heater burned out. 4. Replace crankcase heater.

5. Insufficient oil in system. 5. Add

oil

until sightglass IS

l/3

full.

6. Suction risers too large 6. Check line sizing at

design

conditions and

cha

7. Insufficient traps in suction

risers.

6.

7.

8.

9.

Close switch.

Check electrical circuits and motor winding for

grounds Investigate for possible overloading.

fuse or reset breakers after fault is corrected.

loose or corroded connections.

Overloads are auto reset. Check

unit

closely

w

comes back on line.

Repair

or replace.

Determine

type and cause of shutdown and cc

before resetting safety

switch.

None. Wait until unit calls for cooling

Repair

or replace coil.

Check motor for opens, short circuit, or

burno

Check all

wire

junctions. Tighten all terminal s

shorts or

Replace

Check for

hen

unit

rrect

it

ut

crews.

below.

to load

load.

1. Check for leaks.

Repair

and add charge

2. Clean

chemically.

3. Replace.

4 Clean strainers.

5. Check and reset for proper superheat.

6. Check means for regulating condensing tempe

7. See Corrective Steps below for failure of

comp

unload.

ressor

to

rature.

ressor

to

1.

Clean.

2. Check crankcase heater. Reset expansion val

higher superheat. Check liquid line solenoid vi

operation.

ve

for

alve

hen taking

incorrect.

7.

Install suction P-traps at each 20 foot vertical

nge if

rise.

Continued

on

Next

Page

Page 58 /

IM

269

Loading...

Loading...