to approximately 10 psig and adding sufficient dry nitrogen

to bring the pressure to a maximum of 125 psig. The unit

should then be leak tested with a Halide or electronic leak

detector. After making any necessary repair, the system

should be evacuated as described in the following

paragraphs.

CAUTION: Do not use oxygen to build up pressure. A

serious explosion could be the result.

EVACUATION

After it has been determined that the unit is tight and there

are no refrigerant leaks, the system should be evacuated.

The use of a vacuum pump with a pumping capacity of ap-

proximately 3 cu.

ft./min.

and the ability to reduce the vacuum

in the unit to at least

1

millimeter (1000 microns) is recom-

mended.

The first pull down will remove about 90% of the

non-

condensibles, the second about 90% of that remaining

from the first pull down and after the third only 1

/1

0 of 1

o/o

non-condensibles will remain.

Table 12, page 10, shows the relationship between pressure,

microns, atmospheres, and the boiling point of water.

A mercury manometer, electronic or other type of micron

gauge should be connected to the unit at a point remote

from the vacuum pump. For readings below 1 millimeter,

an electronic or other micron gauge should be used.

The triple evacuation method is recommended and is par-

ticularly helpful if the vacuum pump is unable to obtain

the desired

1

millimeter of vacuum. The system is first

evacuated to approximately 29 inches of mercury. Enough

refrigerant vapor is then added to the system to bring the

pressure up to 0 pounds.

Then the system is once again evacuated to 29 inches

of vacuum. This procedure is repeated three times. This

method can be most effective by holding system pressure

at 0 pounds for a minimum of 1 hour between evacuations.

CHARGING THE SYSTEM

Model ALP condensing units are leak tested at the factory

and shipped with a holding charge of refrigerant. In the event

the refrigerant charge has been lost due to shipping damage,

the system should be charged with enough refrigerant to raise

the unit pressure to 30 psig after first repairing the leaks and

evacuating the svstem.

After all refrigerant piping is complete and the system has

been evacuated, it can be charged as described in the

paragraphs following. Connect the refrigerant drum to the

gauge port on the liquid shutoff valve and purge the charg-

ing line between the refrigerant cylinder and the valve.

Then open the valve to the mid-position.

If the system is under a vacuum, stand the refrigerant drum

with the connection up and open the drum and break the

vacuum with refrigerant gas.

With a system gas pressure higher than the equivalent

of a freezing temperature, invert the charging cylinder and

elevate the drum above the condenser. With the drum in

this position, valves open and liquid refrigerant will flow

into the condenser. Approximately 75% of the total require-

ment estimated for the unit can be charged in this manner.

After 75% of the required charge has entered the con-

denser, reconnect the refrigerant drum and charging line

to the suction side of the system. Again purge the con-

necting line, stand the drum with the connection up, and

place the service valve

in

the open position.

IMPORTANT: At this point charging procedure should be

interrupted and prestart checks made before attempting to

complete the refrigerant charge. See startup procedures on

page 48.

NOTE: It is recommended that the total operating charge

per circuit be stamped on the unit nameplate for future

reference.

HOT GAS BYPASS COMPONENTS

McQuay offers a “Hot Gas Bypass Accessory Kit” for each

ALP unit size. Each kit includes a solenoid valve, a hot gas

bypass valve and an instruction drawing. See page 55 for

hot gas bypass operation.

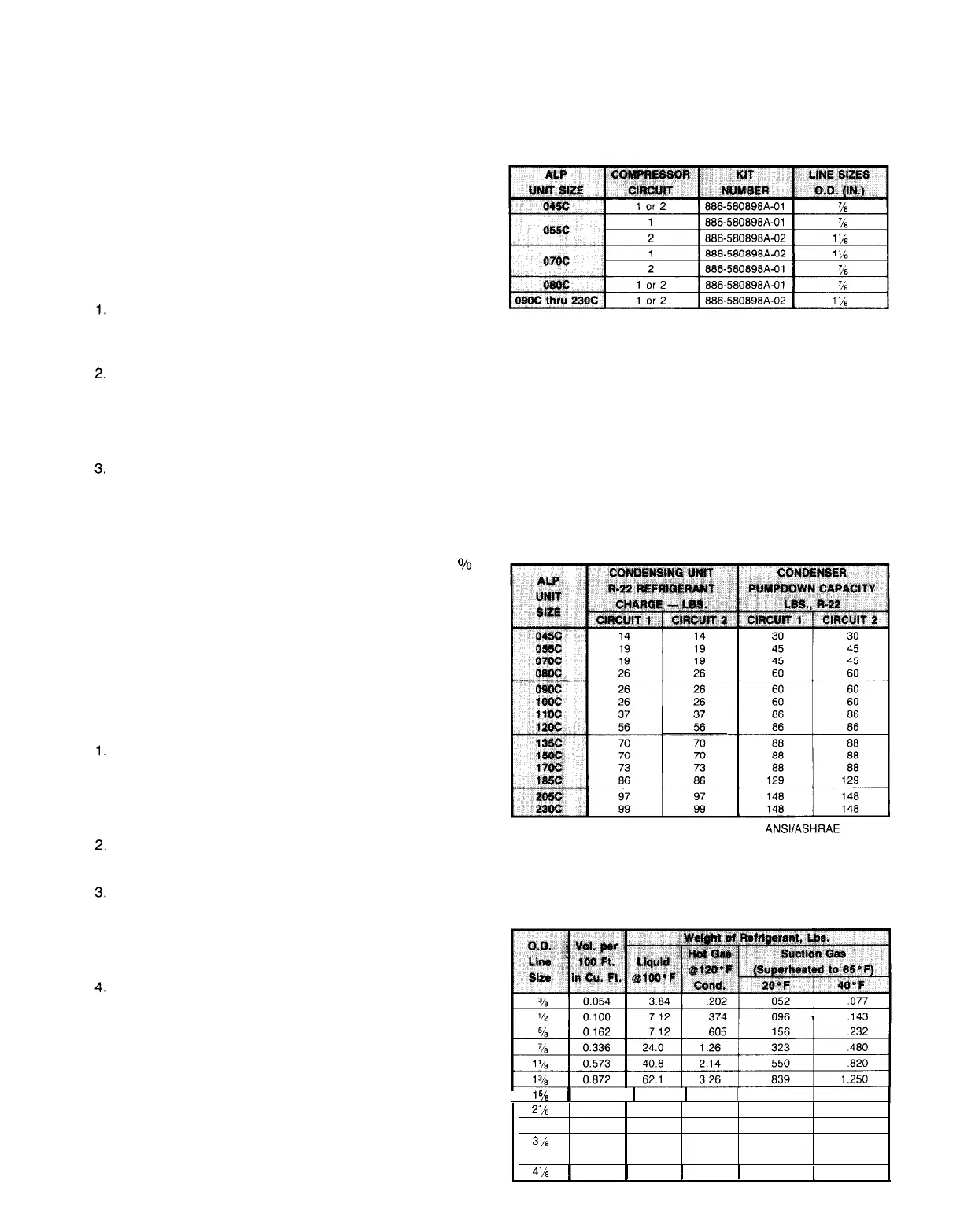

Table 9. Hot gas bypass kits

REFRIGERANT CHARGE

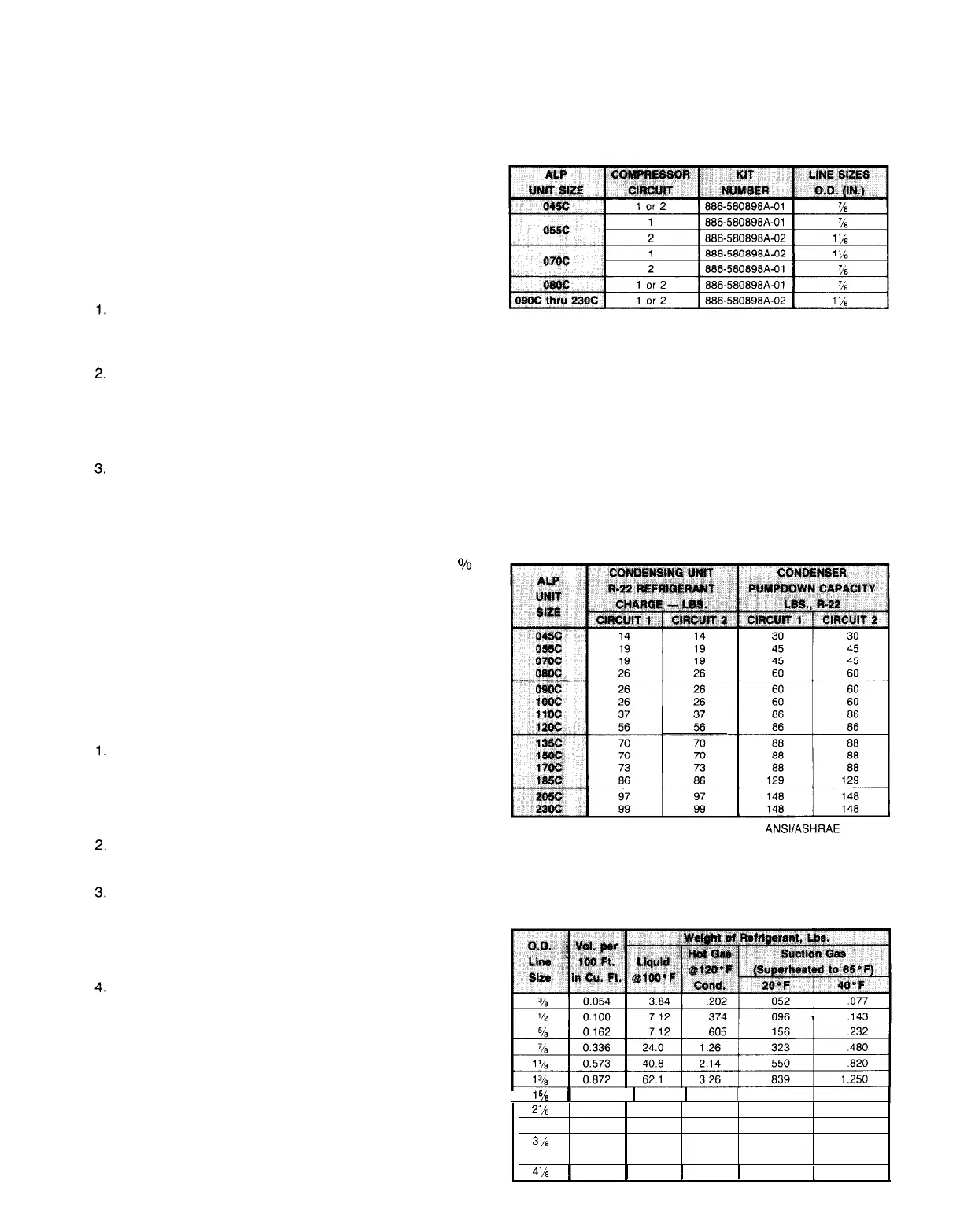

Each ALP condensing unit is designed for use with R-22.

Table 10 lists approximate refrigerant charges for operation

of the unit. Additional refrigerant will be needed for the system

piping and evaporator. Estimated total operating charge

should be calculated before charging system. See Table 11

for weight of refrigerant in copper lines.

CAUTION: Total operating charge per circuit should not

exceed the condenser

pumpdown

capacity per circuit. A li-

quid receiver on each refrigerant circuit could be used in this

situation. Refer to the

ASHRAE

Handbook for the design and

installation of piping and components.

Table 10. Approximate refrigerant charge

NOTE: Condenser

pumpdown

capacity is based on ANWASHAAE Standard

15-1978 rating of 90% full of liquid at 90°F. To convert values to the older

ARI

standard (80% full at 80°F). multiply

pumpdown

capacity by 0 888.

Table 11. Weight of refrigerant R-22 in copper lines

(Pounds Per 100 Feet of Type L Tubing)

is/8

1

1.237

1

88.0

1

4.62

1

1.190 1.770

2’h

2.147 153.0 8.04 2.06 3 060

2%

3.312 236.0 12.4 3.18 4.720

31/a

4.728 336.0 17.7 4.55 6.750

3%

6.398 456 0 24.0 6.15 9.140

4’ia

1

8.313

1

592.0

1

31.1

1

8.00

1

11.190

IM

269 I Page

9

Loading...

Loading...