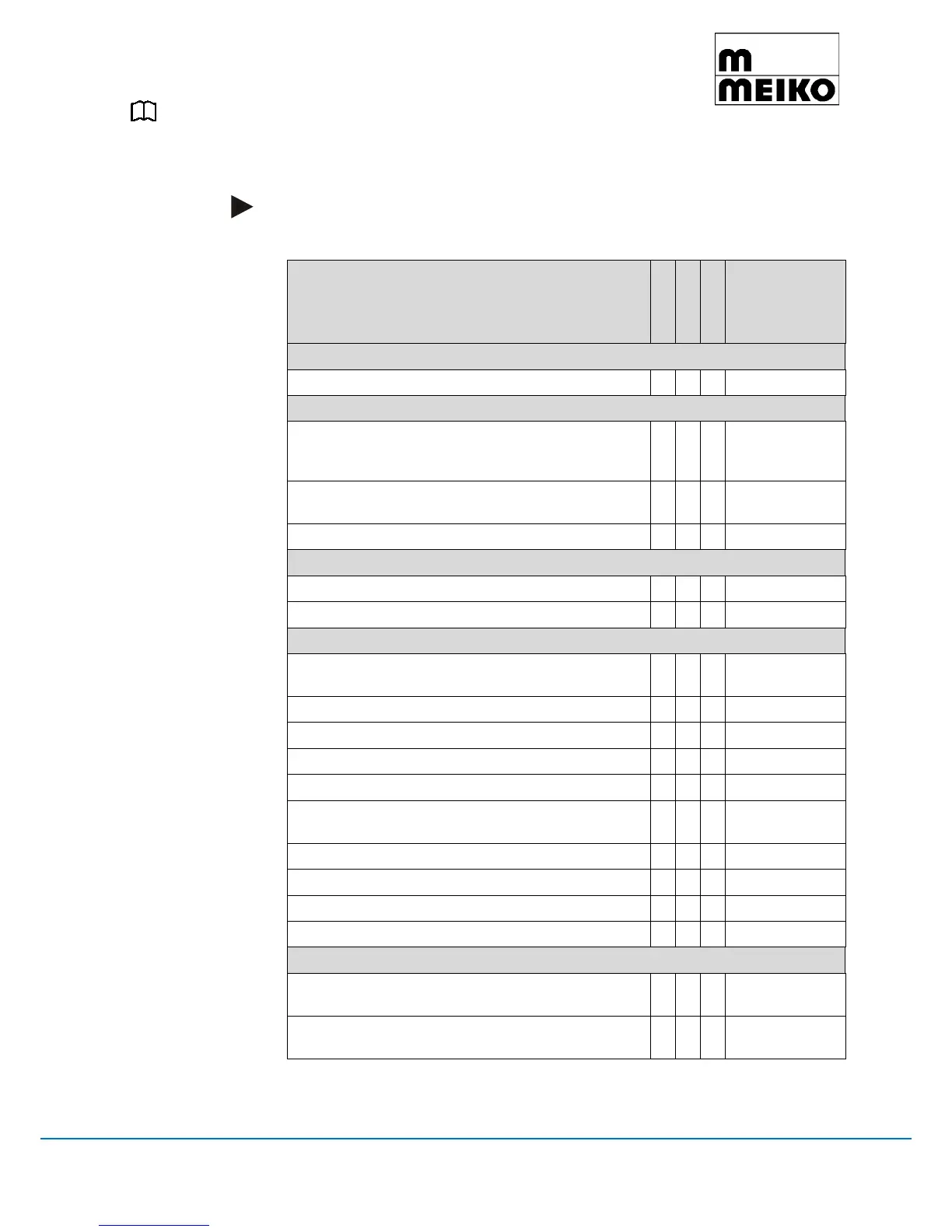

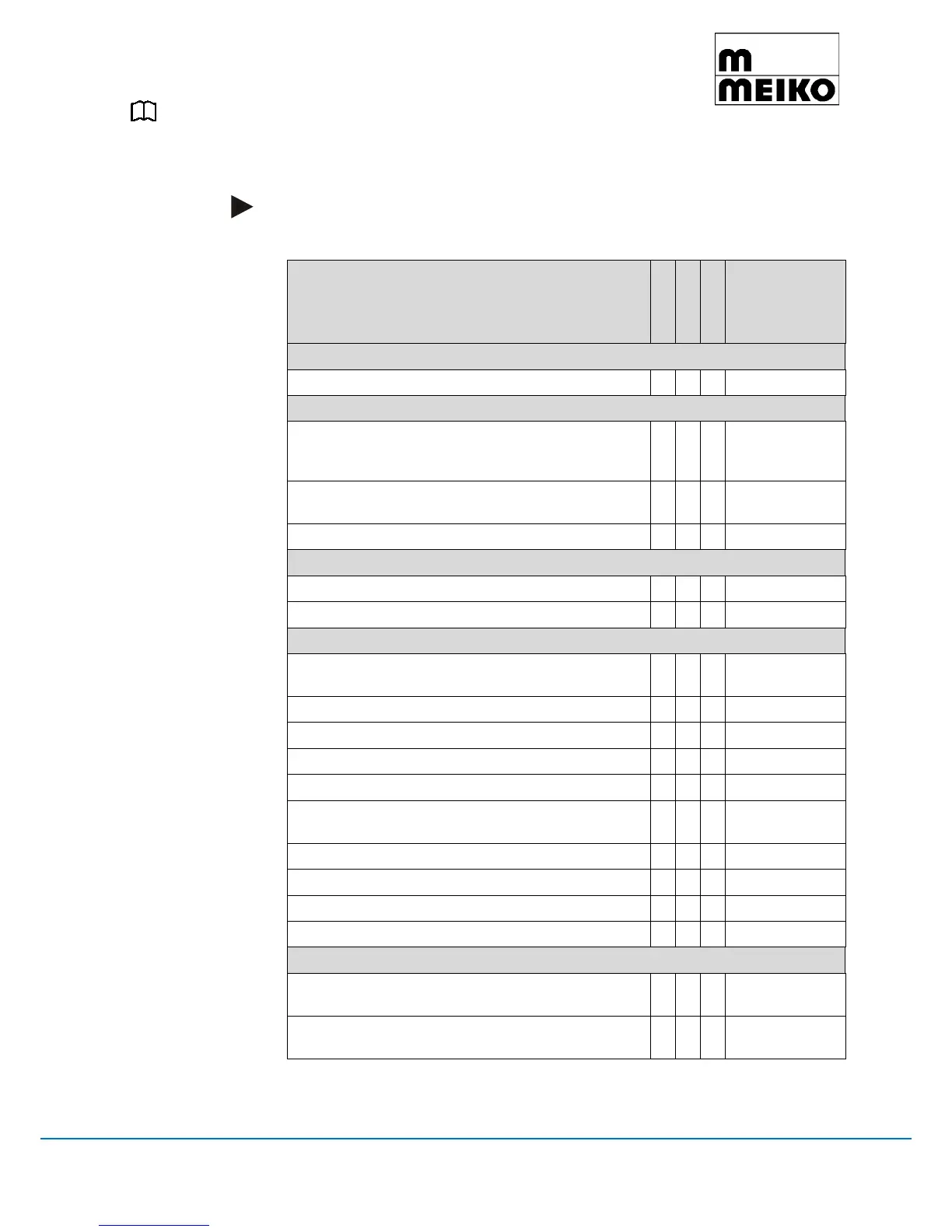

Maintenance

specification

1. Error memory

Check error memory for unusual events. annually

2. Electrical installation

Re-tighten all screw connections (e.g. heating con-

tactors, control fuse), check plug/terminal connec-

tions.

annually

Carry out a visual check on all electrical equipment

(e.g. switches, cables, plugs, etc.).

annually

Check tank and boiler heating. annually

3. Pumps

Check pumps for leaks and any visible damage. annually

Check pumps for pump rotor noise and function. annually

4. Wash tank, wash and final rinse system

Functional and visual inspection of the washing and

final rinse arms.

annually

Replace sealing ring wash arm. annually

Check the air trap tank. annually

Check the level control tank is not leaking. annually

Check sieves and filter. annually

Check that the wash and final rinse system is not

leaking.

annually

Check water level in tank. annually

Check door seal. annually

Check seal on coarse sieve/drain pump. annually

Replace flap ventilating valve. annually

5. Housing

Check housing, tank and cladding for damage and

correct operation.

annually

Check door and door counter balance for correct op-

eration.

annually

Loading...

Loading...