RIGHT HAND NON-RATCHETING

Page 6A-18 90-855347R1 JANUARY 1999

NOTE: If Step 8-b was used to remove propeller shaft, the shift cam can be retrieved after

removal of forward gear.

Shift Shaft

CLEANING AND INSPECTION

1. Clean shift shaft and bushing with solvent and dry with compressed air.

2. Check shift shaft splines on both ends for wear and/or corrosion damage.

3. Inspect shift shaft for groove(s) at shift shaft bushing seal surface.

4. Inspect shift shaft bushing for corrosion damage.

5. Inspect shift shaft bushing oil seal for wear and/or cuts.

NOTE: Oil seal in shift shaft bushing should be replaced as a normal repair procedure.

DISASSEMBLY

1. Remove (and discard) shift shaft bushing oil seal by prying it out or driving it out with

a punch and hammer.

CLEANING/INSPECTION - BEARING CARRIER

IMPORTANT: It is recommended that all seals and O-rings be replaced (as a normal

repair procedure) to assure effective repair.

1. Clean bearing carrier with solvent and dry with compressed air.

CAUTION

DO NOT spin bearings dry with compressed air, as this could cause bearing to

score.

2. Bearing carrier propeller shaft needle bearing condition is determined by propeller

shaft bearing surface condition. (See “Propeller Shaft Inspection.”)

3. Inspect reverse gear to pinion gear wear pattern (should be even and smooth). If not,

replace reverse gear and pinion gear.

4. Check clutch jaws on reverse gear for damage. Replace reverse gear, if damage is

found on clutch jaws.

5. Apply light oil to reverse gear bearing. Rotate reverse gear bearing while checking

bearing for rough spots and/or catches. Push in and pull out on reverse gear to check

for bearing side wear. Replace bearing if any of the listed conditions exist.

DISASSEMBLY - BEARING CARRIER

1. Remove and discard O-ring from between bearing carrier and thrust washer.

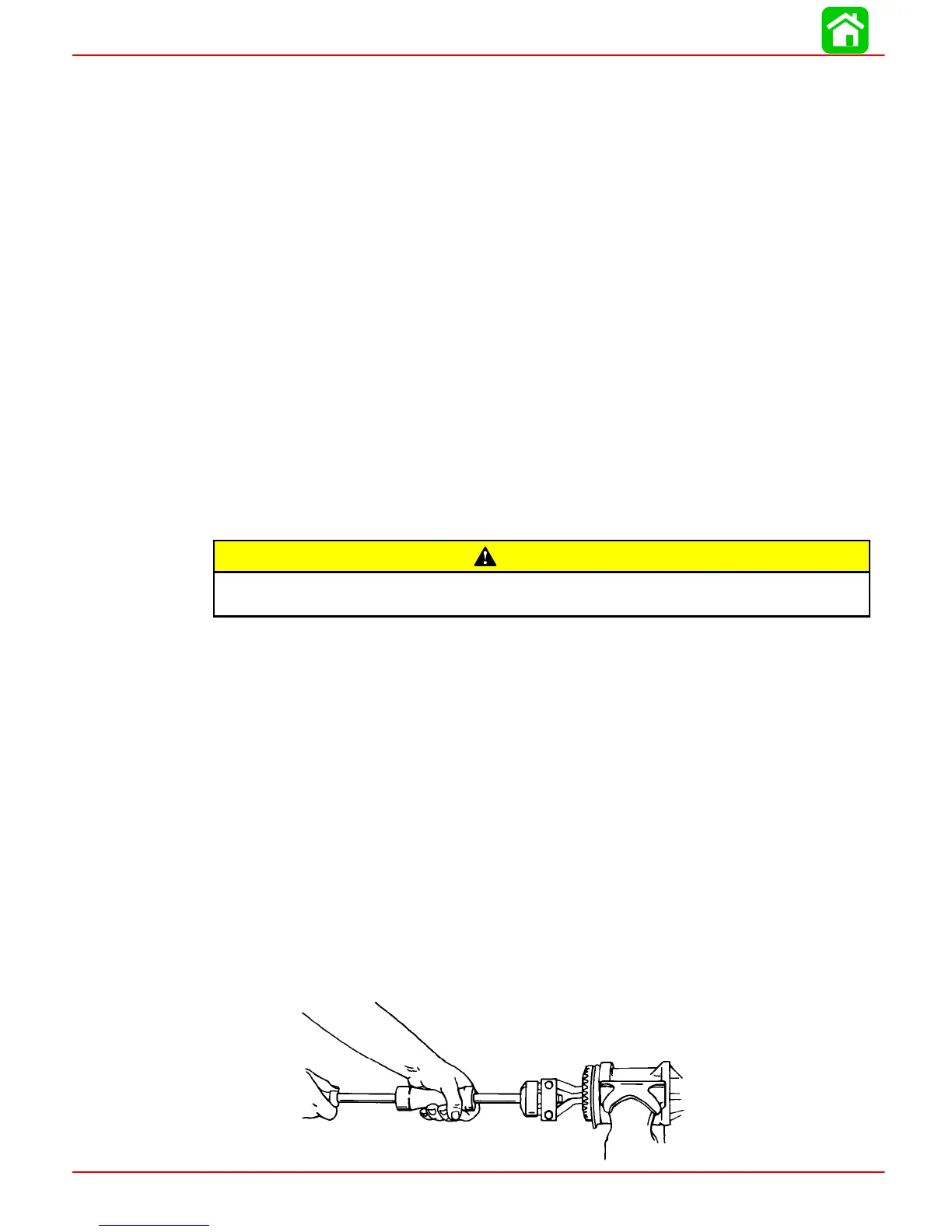

2. If inspection of reverse gear or reverse gear bearing determines that replacement of

gear or bearing is required, remove gear and bearing as follows:

a. Position bearing carrier in a soft jaw vise.

b. Use Slide Hammer (91-34569A1) and remove reverse gear.

51868

Loading...

Loading...