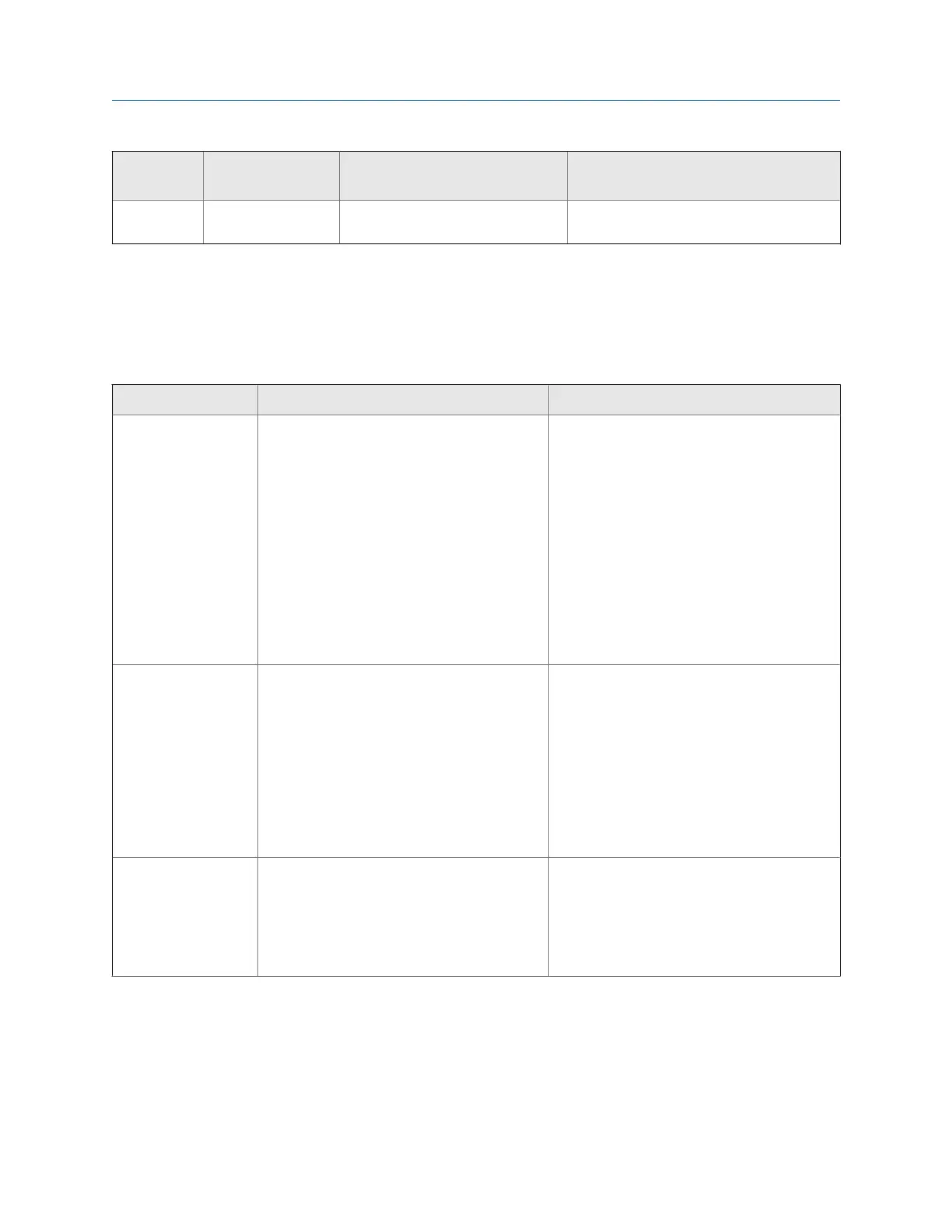

Alert num-

ber Alert title Possible cause Recommended actions

N/A Zero Calibration in

Progress

A zero calibration is in progress. • No action required.

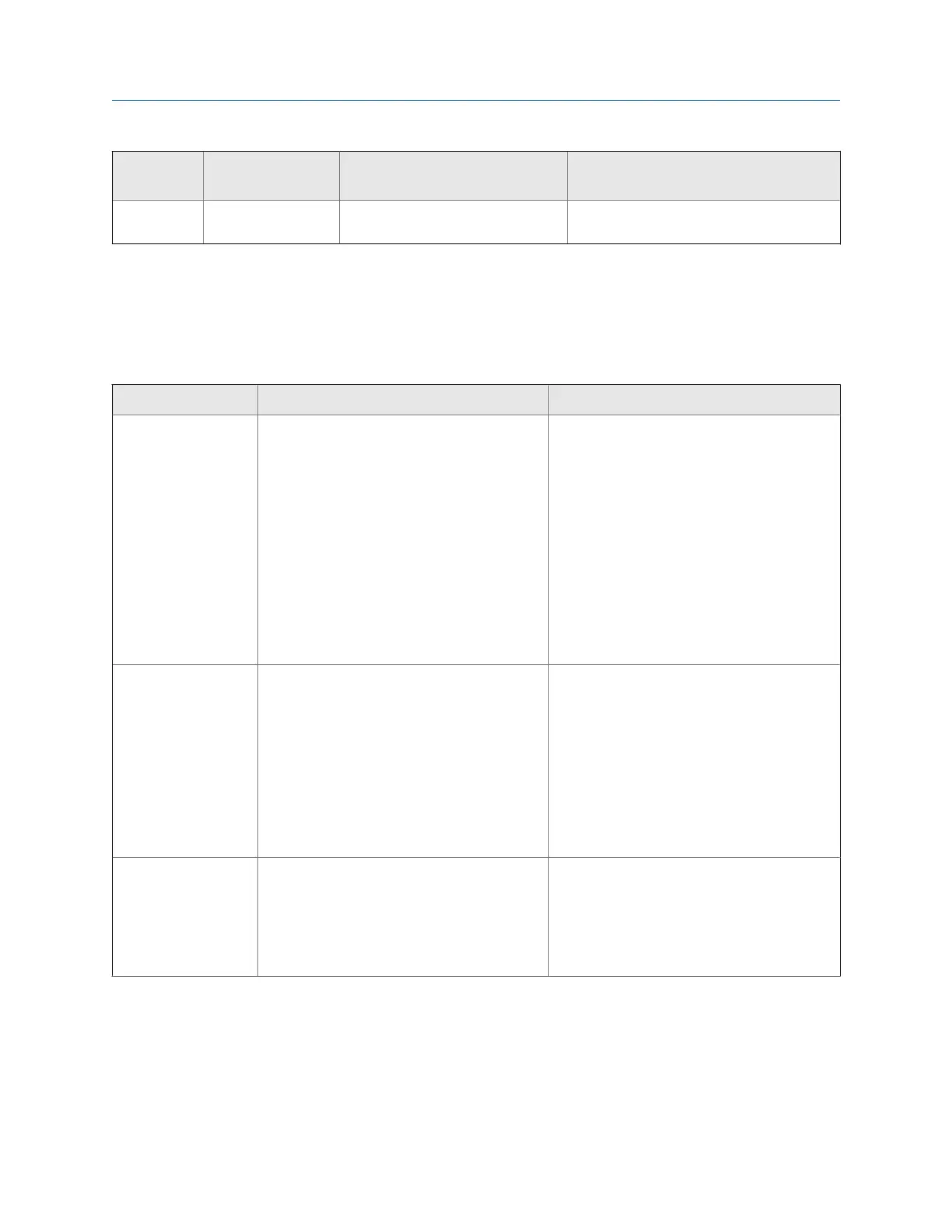

10.7 Density measurement problems

Density measurement problems and recommended actionsTable 10-2:

Problem Possible causes Recommended actions

Erratic density reading • Normal process noise

• Two-phase flow

• Flow rate too high

• Contaminants or suspended solids in the

process fluid

• Vibration in the pipeline

• Erosion or corrosion

• Check your process conditions.

• Increase the density damping value.

• Reduce the flow rate.

• Check for two-phase flow. See

Section 10.23.

• Ensure that line pressure or sample pres-

sure meets installation requirements.

• Increase back pressure to minimize bubble

formation.

• Minimize vibration in the pipeline.

• Install a flow control method (bypass, flow

chamber, expander, etc.).

• Perform Known Density Verification.

Inaccurate density

reading

• Inaccurate temperature measurement

• Incorrect calibration factors

• Contaminants or suspended solids in the

process fluid

• Verify the temperature reading from the

RTD (on-board temperature sensor).

• Verify the temperature reading from the

external temperature device, if applicable.

• Verify or adjust the density offset and/or

the density meter factor.

• Increase the flow rate.

• Install a thermal insulation jacket.

• Verify the calibration factors.

• Perform Known Density Verification.

Density reading too

high

• Plugged or coated flow tube

• Inaccurate temperature measurement

• Incorrect calibration factors

• Erosion or corrosion on the sensor tubes

• Purge the flow tubes.

• Check for coating on the flow tubes.

• Verify the temperature reading from the

RTD (on-board temperature sensor).

• Verify the temperature reading from the

external temperature device, if applicable.

Troubleshooting

Configuration and Use Manual 149

Loading...

Loading...