Troubleshooting (cont.)

Checking Individual Components

29

CONSOLE

The only way to field test a console is to connect it to a

harness on a vehicle with a known working MT-3000 system

or install it on an EPOP (electronic point of purchase) display

stand. NEVER try to direct wire the connector of an MT-3000

console.

HARNESS

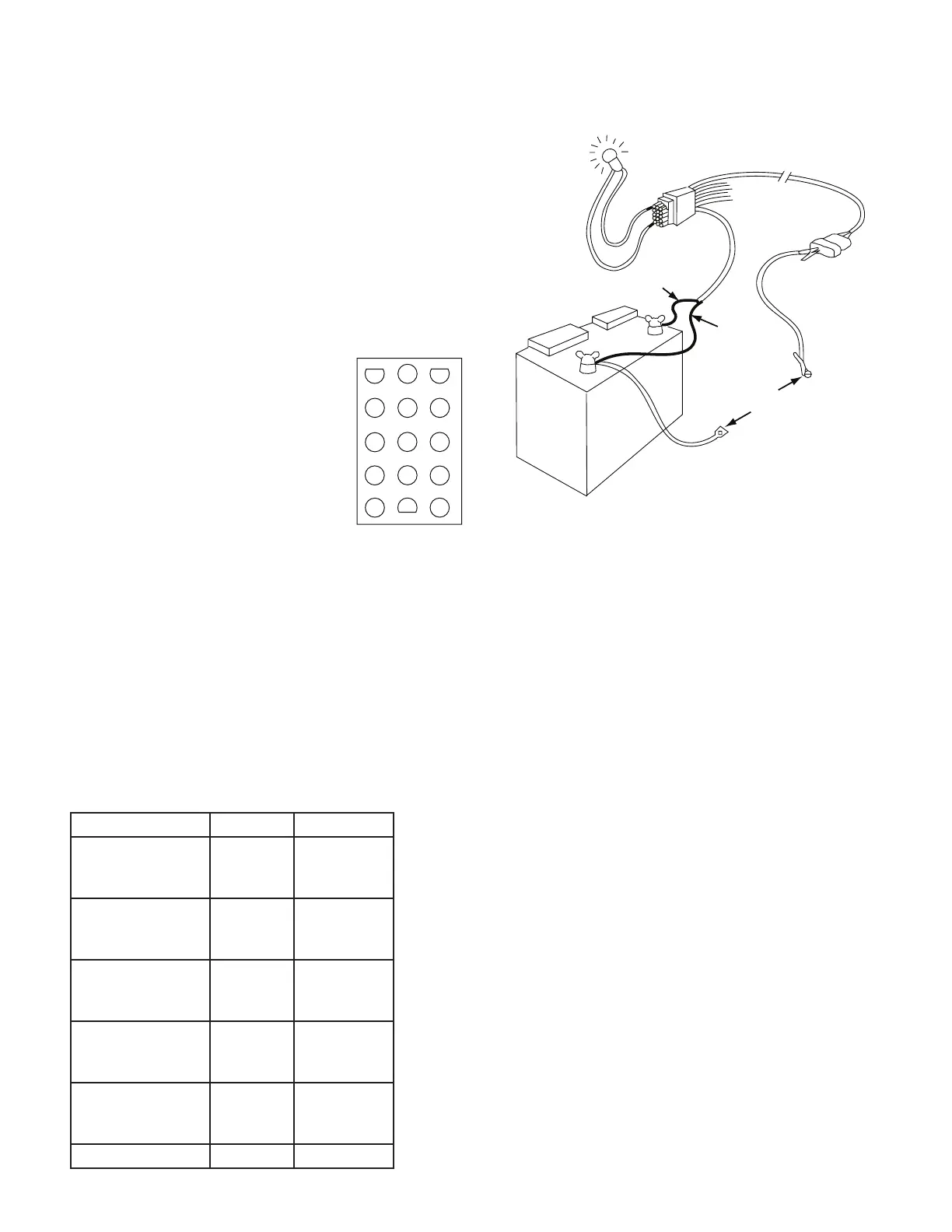

The main harness can be checked using a DC Volt Meter

or test light. Unplug the main harness from the console.

Disconnect all three-pin connectors (speed, flow, remote

run/hold, servo and boom solenoids). Connect all power

wires . See page 11.

Connect one test probe to a good frame

ground. Touch the other test probe to

pin 13 of the harness connection. See

Illustration to the right. Power should be

present (meter reads about 12 V or test

light lights.). If no power, check the large

orange wire to battery. Now touch one

probe to pin 13 and the other to pin 7.

If no power, check the large blue wire to

the battery.

Now touch one probe to pin 10 and the other to pin 7. Power

should be present when the ignition switch is turned on. If

not, check the small orange power wire.

To test the rest of the harness, use a clip lead or other jumper

wire to ground the pin indicated by the following chart.

Connect one test probe to pin 13 and touch the other probe

to all the other pins one at a time. The chart shown which

ones should have power. If too many pins have power, there

is a short in the harness. If the indicated pins do not have

power, there is a poor connection at the large orange battery

wire, or the grounding jumper, or a break in the harness.

There should always be power between pions 13 and 7.

ELECTRICAL INTERFERENCE

Erratic operation may be a result of electrical interference

from ignition wires or inductive loads (electric clutch, fan,

solenoid, etc.). You may need to relocate the console and/or

wiring or install noise suppressor and/or resistor spark plugs

or wires.

ACCESSORY POWER

The white wire of the main harness speed, flow and remote

Run Hold cables supplies 12 volt power to optional accessories

such as the Trak-Star Ultrasonic Speed Sensor. If this wire

shorts to ground, the console’s thermal overload will trip and

shut down the entire MT-3000 system. Remove the short

and turn power off for 30 seconds to reset.

INPUTS

Provided the main harness checks out OK, the console’s

speed and flow inputs can be checked fa follows:

• If checking speed, turn to speed and disconnect the

speed sensor (yellow tie).

• If checking flow, turn to flow rate and disconnect the

flow sensor (green tie).

Then using a clip lead or other jumper wire (paper clip bent

in a “U”) short together several time rapidly. The two outside

pins of the appropriate connector of the main harness are

OK. If the monitor does not respond, the monitor or the main

harness is defective.

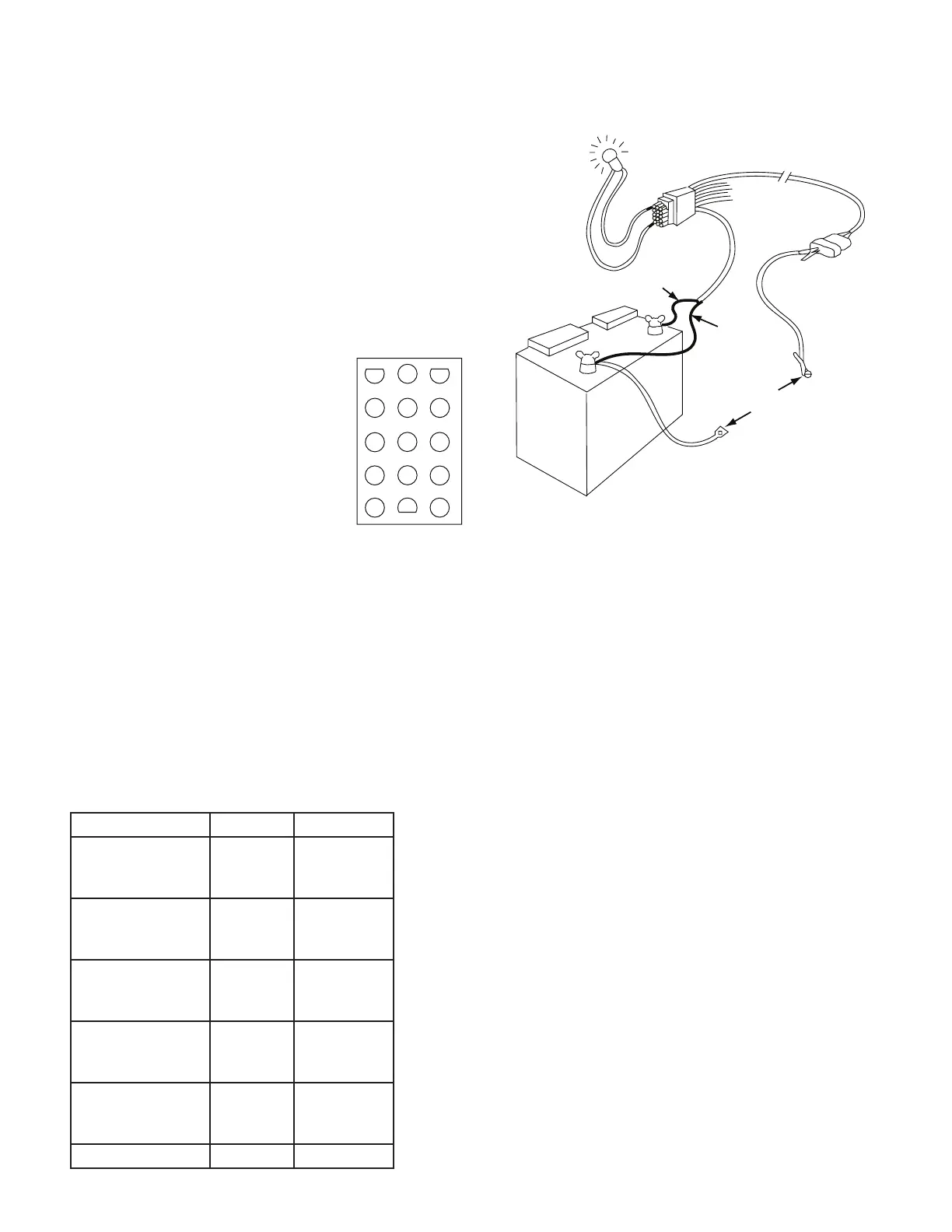

1 2 3

4 5 6

7 8 9

10 11 12

13 14 15

PINS 1, 3 & 14

POWER FROM

PIN 13 TO PIN

INDICATED BY

CHART TO RIGHT

12 VOLT

TEST LIGHT

SHOULD LIGHT

GROUND THE

WIRE INDICATED

BY THE CHART

ORANGE

BLUE

GROUND

Ground this Pin Wire Color Power at Pin

Remote Run/Hold

(Shortest Cable)

Red

White

Black

1

4

2

Speed Input

(Yellow Tie)

Red

White

Black

8

4

2

Flow Input

(Green Tie)

Red

White

Black

5

4

2

Boom Solenoids

(Black Tie)

Red

White

Black

12

9

6

Servo Valve

(Reversed Connector)

Red

White

Black

15

11

14

Small Brown Wire 3

Loading...

Loading...