38

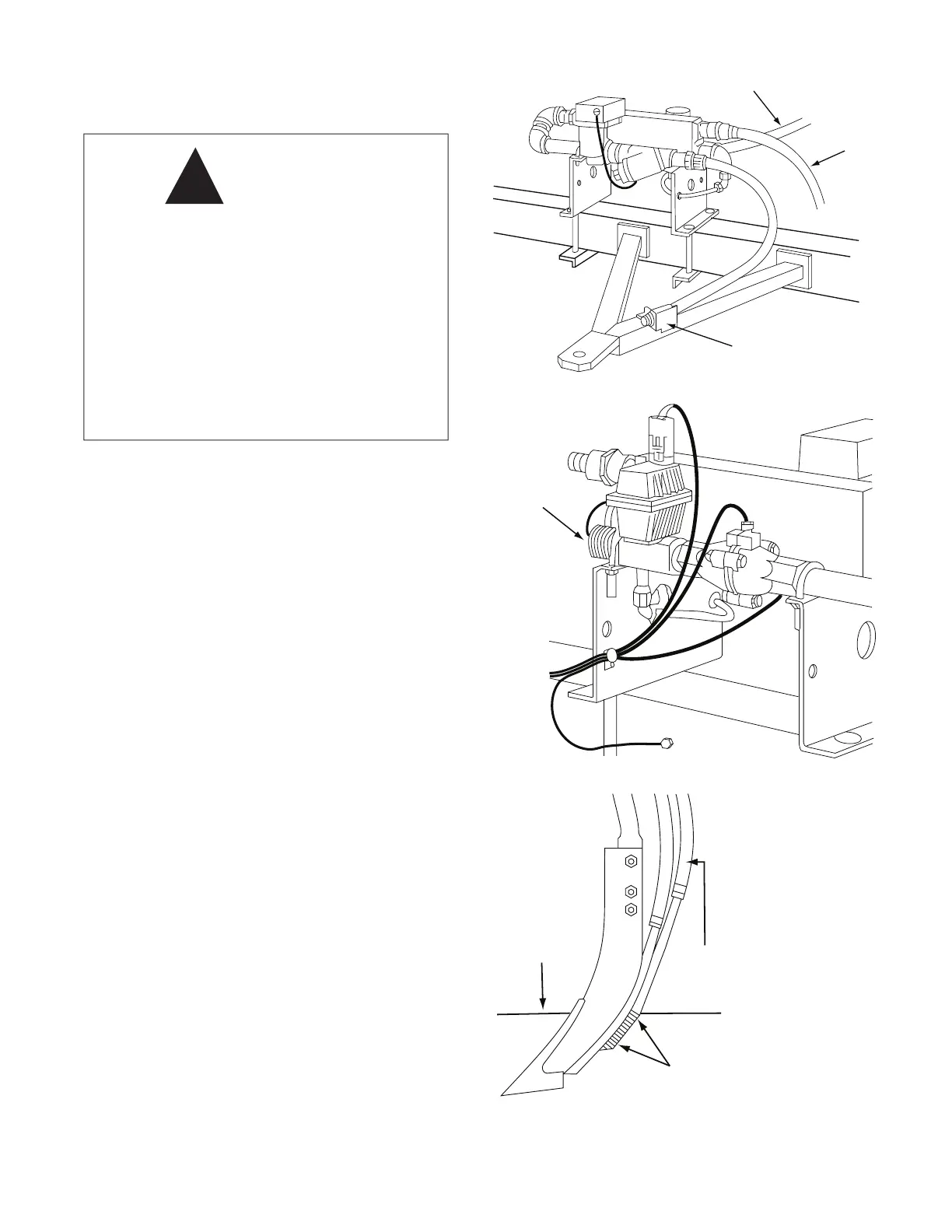

PLUMBING

Remove your existing metering valve system. If the old

metering valve has a built-in manifold, you must install a

separate manifold. No positive shut-off valve(s) may be

installed in the system after the NH3500’s shut-off valve.

Locate a convenient spot on the applicator to install the

system. The break-a-way coupler hose must reach the

stainer inlet with enough slack to allow proper operation

of the disconnect mechanism. The strainer’s clean-out plug

should be accessible for cleaning. Bolt the system to the

frame using four ½” x 7” carriage bolts and flange lock nuts

through the top and bottom brackets. Trim the length of

the bolts if required. Attach the break-a-way coupler hose to

the strainer input. Connect the manifold hose to the servo

valve outlet.

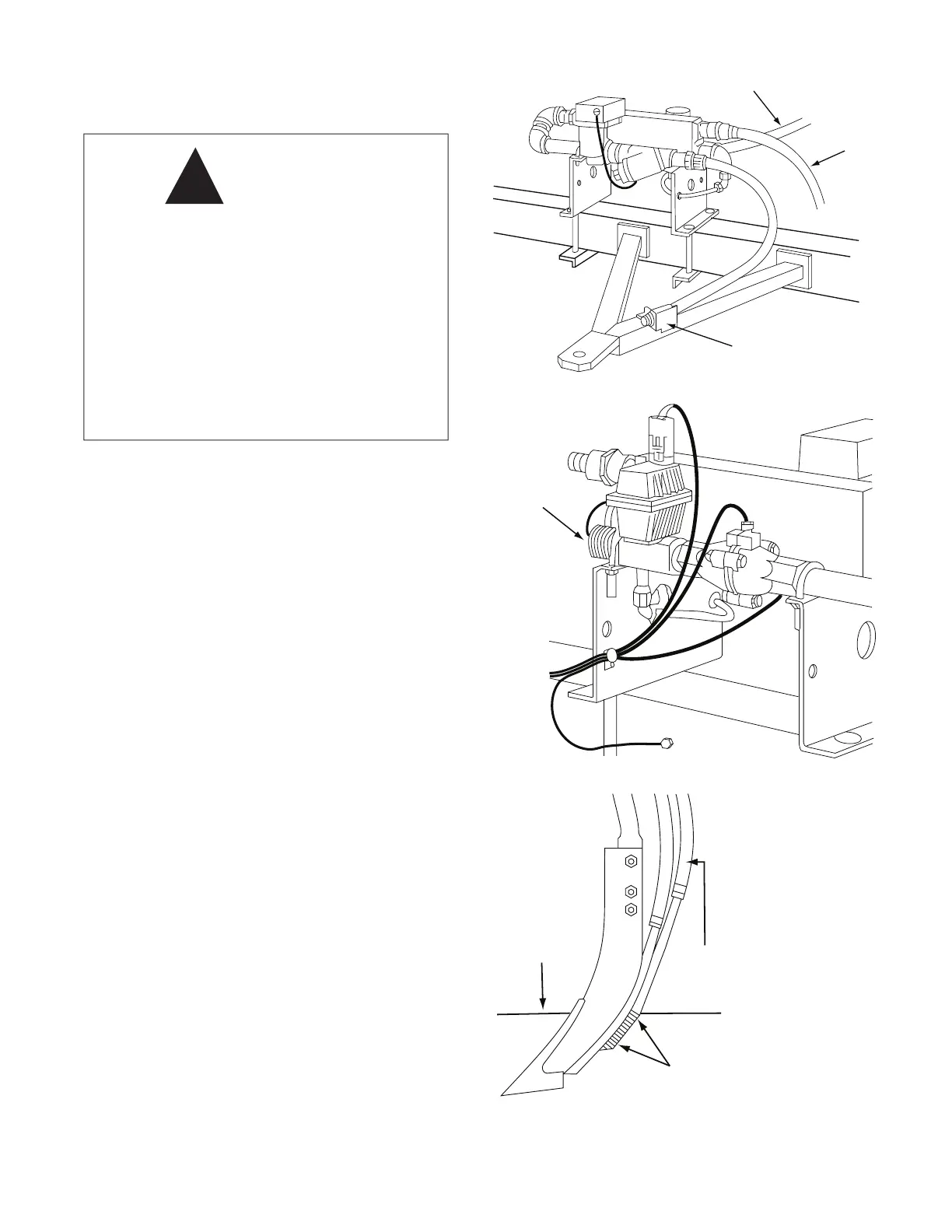

Weld the vapor tubes to the back of your liquid tubes.

ALL ELECTRONIC EQUIPMENT, including the console and

Trak-Star Speed Sensor, MUST BE DISCONNECTED BEFORE

WELDING ON EQUIPMENT. The four vapor tubes should

be evenly spaced across the applicator and installed so that

only their wear resistant surface contacts the soil. Mount the

tubes just high enough to avoid plugging.

TO MANIFOLD

TO

VAPOR

TUBES

BREAK-AWAY

COUPLER

Anhydrous Ammonia (cont.)

Installation

!

WARNING

Always follow standard safety

procedures and use proper

safety equipment when working

on anhydrous ammonia equipment

Before working on plumbing:

• Disconnect nurse tank.

• Remove all ammonia from system

• Leave all valves on applicator open.

O MANIFOLD

GROUND

LEVEL

VAPOR

TUBE

WEAR

RESISTAN

SURFACE

Loading...

Loading...