39

Anhydrous Ammonia (cont.)

Installation (cont.)

PLUMBING (cont.)

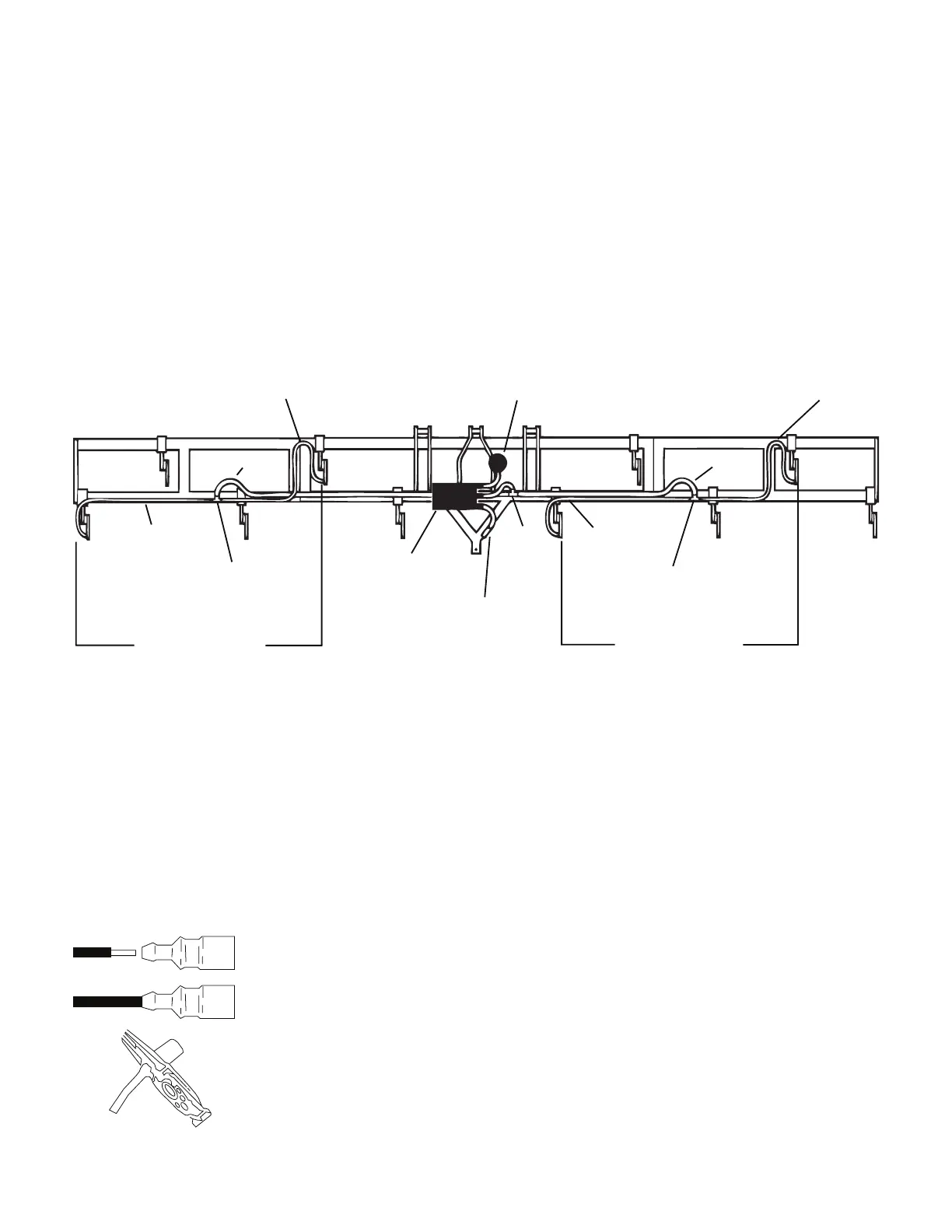

Connect ½” EVA hose to an outside vapor tube and route

along the applicator frame to the next vapor tube. Allow

extra hose to minimize kinking at hinge points. Cut to length

(make sure enough hose is left for other side) and attach the

hose to the second vapor tube. Install a ½” x ½” x ¾” tee

about halfway along this hose. Repeat for the other side.

Connect the tees using an appropriate length of ¾” EVA hose

routed along the frame. Install a ¾” tee about halfway along

this hose. Connect a ¾” hose to the tee and route to the

hose barb on the heat exchanger. Cut to length and install.

Secure all hoses with properly sized hose clamps. Attach the

hoses to the frame with cable ties

NOTE: NEVER USE THE MT-3000 CONSOLE PRESSURE

GAUGE WITH ANHYDROUS AMMONIA.

This gauge contains brass and is not compatible with NH

.

It is unsafe to bring any equipment containing NH

into the

operator’s area. Use a gauge approved for NH

installed on

the applicator’s manifold.

½” Vapor Hose

Breakaway

Coupler

NH3500 Kit

Steel Vapor Tubes

½” Vapor Hose

Manifold

½” Vapor Hose

½” Vapor Hose

¾” Vapor Hose

½” X ½” X ¾” Tee

¾” Tee

½” X ¾” X ½” Tee

Steel Vapor Tubes

¾” Vapor Hose

INSTALLATION OF VAPOR TUBES

ELECTRICAL

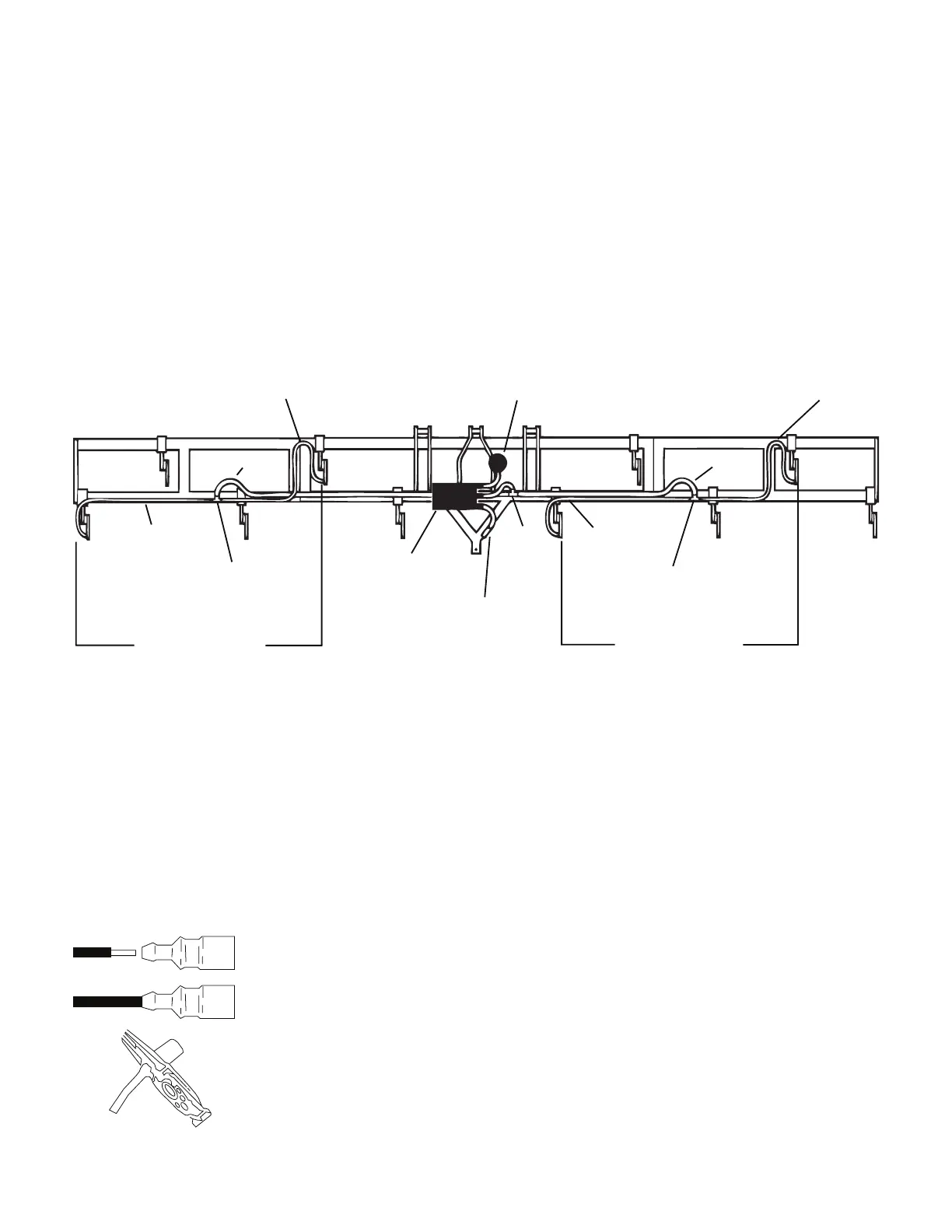

The NH3500 main wiring harness is made specifically for use

on anhydrous ammonia applicators. The harness combines

the wires for the servo valve, flowmeter and shut-off valve

into a single six pin connector.

The cable to the battery includes a user installed 7 ½ amp

fuse and fuse holder. Install the fuse holder (see illustration)

on the orange (hot) lead near the battery cable has been cut

to length. See the console operator’s manual for additional

power cable wiring details.

INSTALLATION

STEP 1

STEP 2

STEP 3

1. Strip insulation from wire

(approximately 3/8”/1 cm).

2. Insert wire in holder.

3. Crimp terminal through

body.*

4. Insert fuse.

5. Snap housing together.

* Recommended Crimping

Tools:

Thomas & Betts No. WT-1300

Radio Shack No, 64-40

General Electric - US & Metric Electrical

Terminal Tool.

Plug the main harness six pin connector into the Hold Cutout

Module which should already be connected to the plumbing

unit harness. Optional extension cables are available. Use

black plastic ties to secure the Hold Cutout Module to the

applicator.

NOTE: Remote Run/Hold is not available on the NH

systems.

Connect the heat exchanger’s blue wire to an unpainted

location on the applicator frame with a ¼” ring terminal.

Connect one end of the roll of blue wire to the applicator’s

frame with a ¼” ring terminal. Route this wire to the hitch

area and connect a male .250 connector. Perform a similar

operation on the tractor, terminating the wire with a female

.250 connector. Connect the blue wires together at the

hitch.

Loading...

Loading...