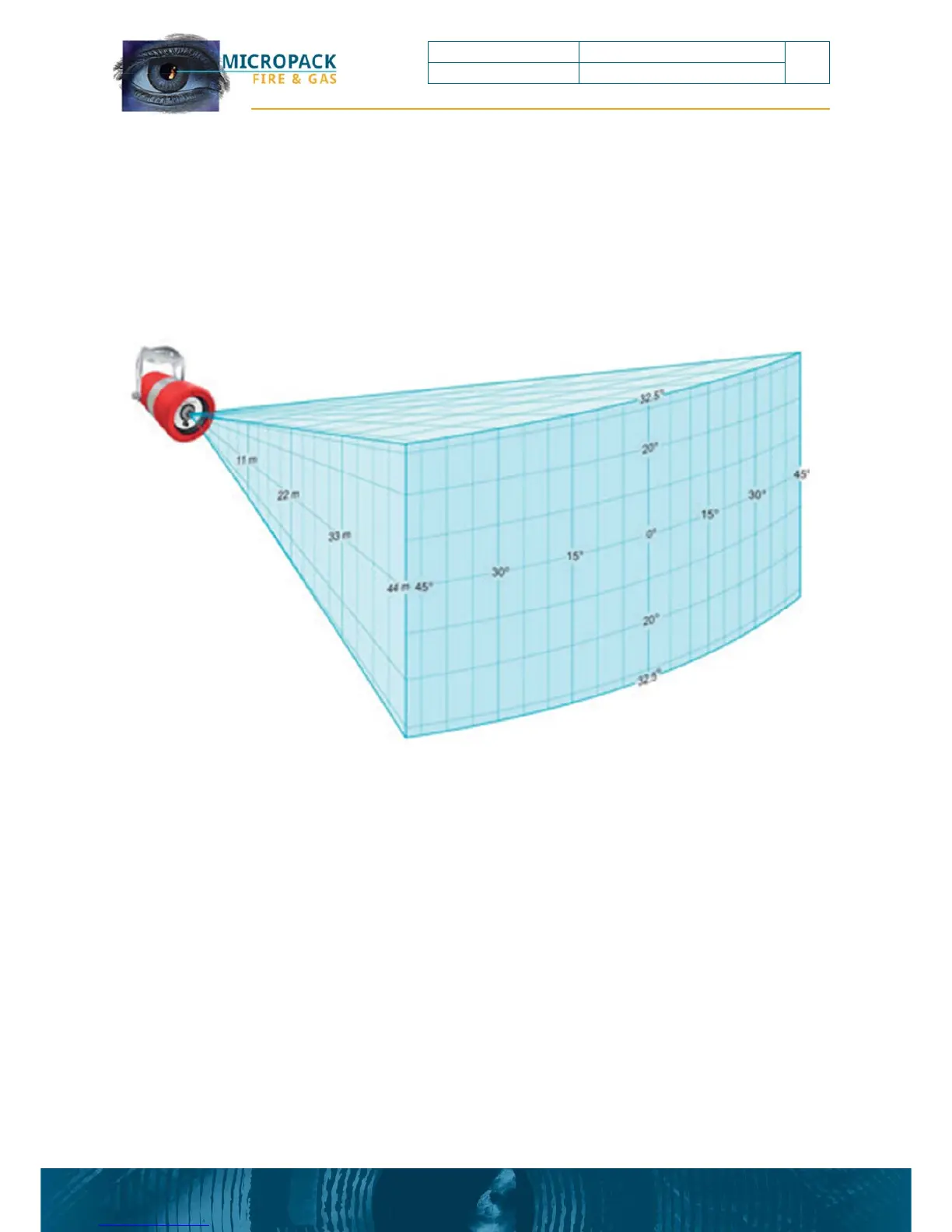

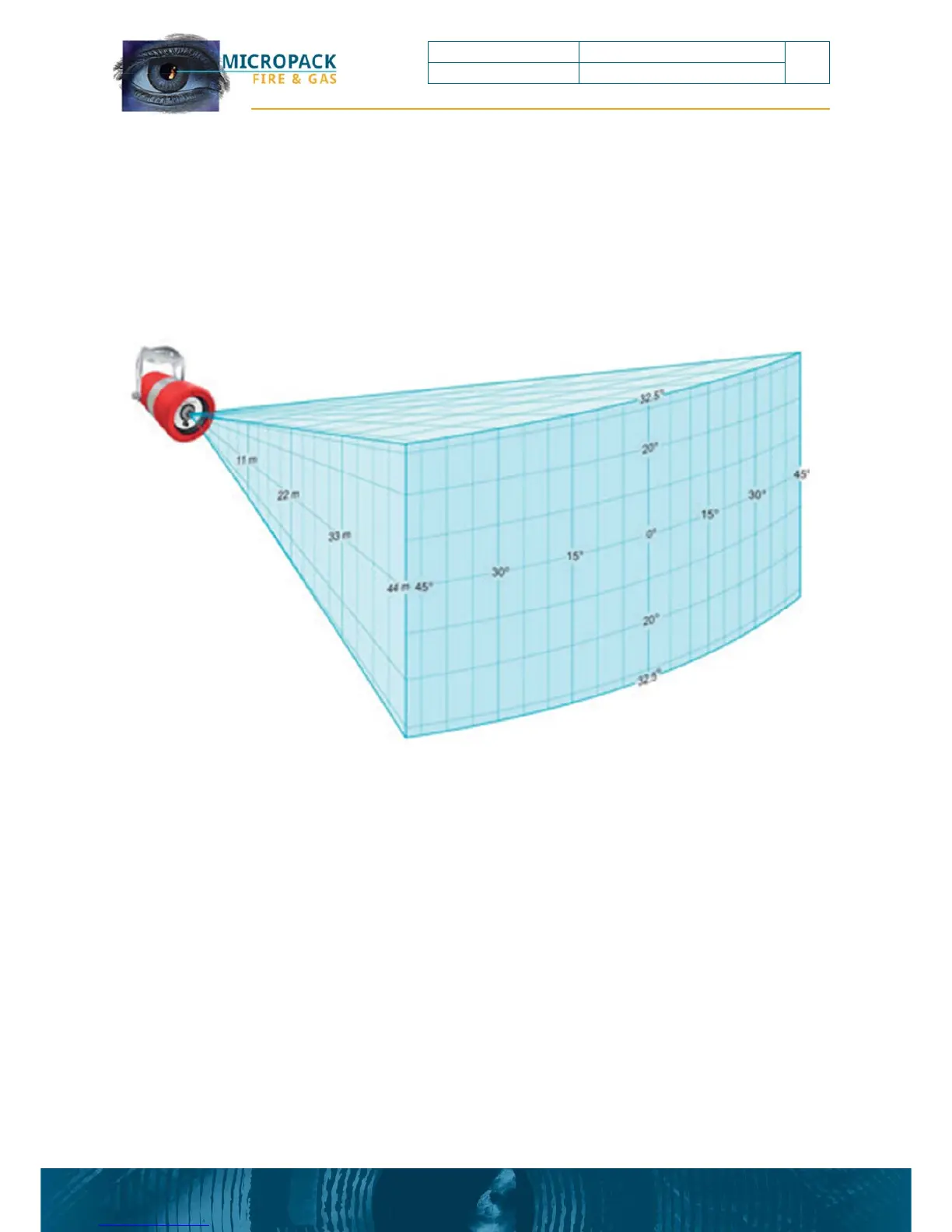

Detector locations can be chosen from computer models or from site surveys. The detectors

should be aligned to view the intended hazard taking into account any obstruction and

congestion.

Fi

of the hazards. This analysis can also be used to optimise the number of detectors.

5.3

Flame detectors are frequently used where hydrocarbon fire hazards are expected; these are

lants where a flare stack is in use nearb

. The detector should not have a

direct view of the flare.

5.4

There are many sources of contamination such as oil, water (deluge water, rain and sea-spray),

snow, ice, and internal misting. The design of the detector incorporates an internal heater in order to

resist condensation and ice build-up. Excessive contamination of the detector faceplate may result

in an increased maintenance requirement and potentially reduce the detector’s sensitivity. Where

detectors are mounted at low level, care should be taken to avoid contamination (such as water

and oil) from equipment above the detector. Care should be taken in sighting the detector to

minimise the likelihood of such contamination.

micro

FDS301 Flame Detector FDS301 Safety and Technical Manual

22

Ref: 2200.5009 Rev: 2.3 ECN 4434

Loading...

Loading...