Flooded type water cooled screw chiller (PCB Control) MCAC-CTSM-2012-11

47

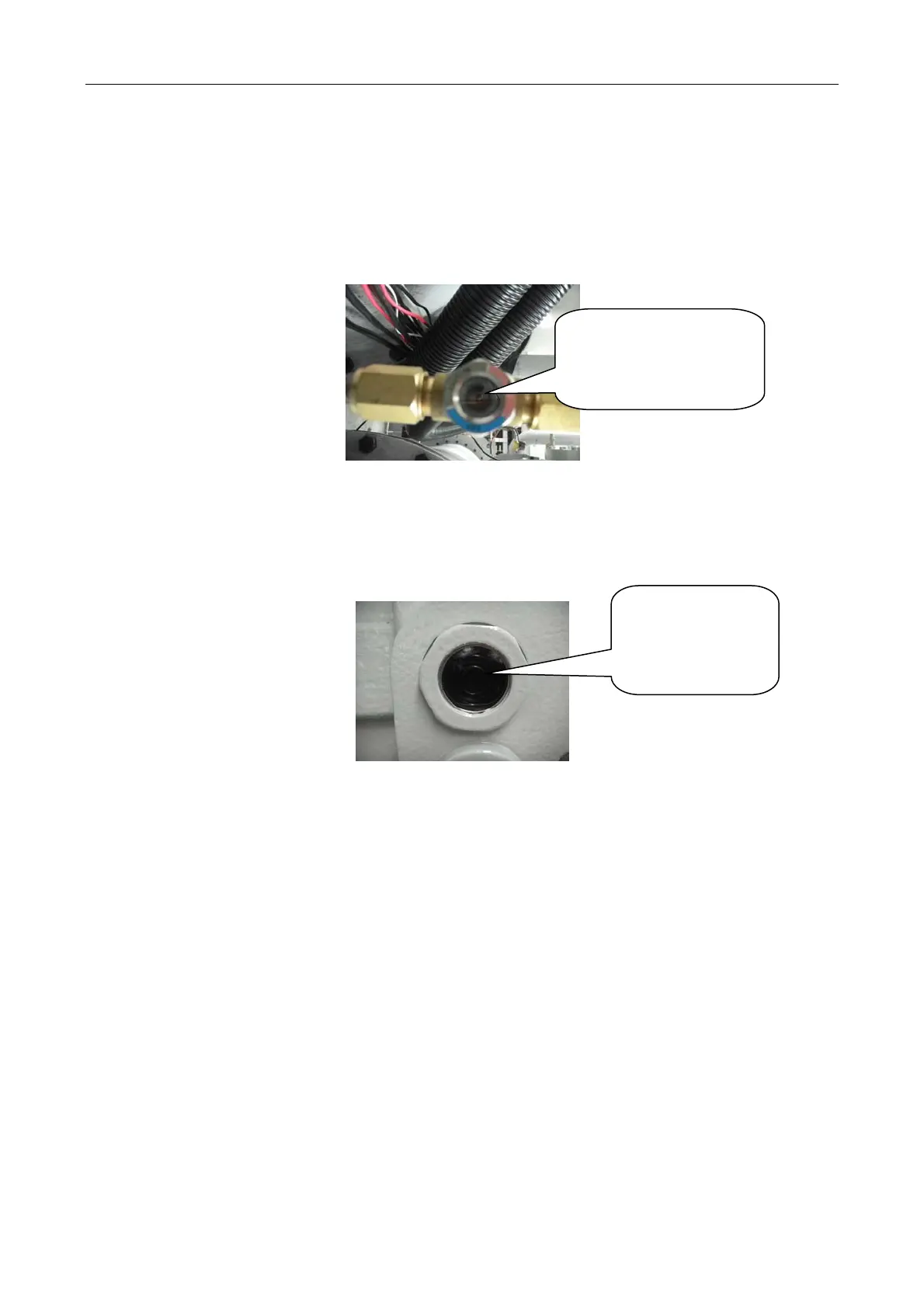

2) Inspect whether moisture content of the system exceeds the limit

Excessive moisture content in the refrigerant system of the unit might cause ice block, copper

plating, etc. that would seriously affect the safety of the unit. Therefore, the dryness of the

refrigerant system of the unit shall be inspected from the sight glass before and during

operation of the unit, purple indicating dry, and pink moist, as shown in the right figure. When

the color turns red, the filter core in the unit shall be replaced with a dry one.

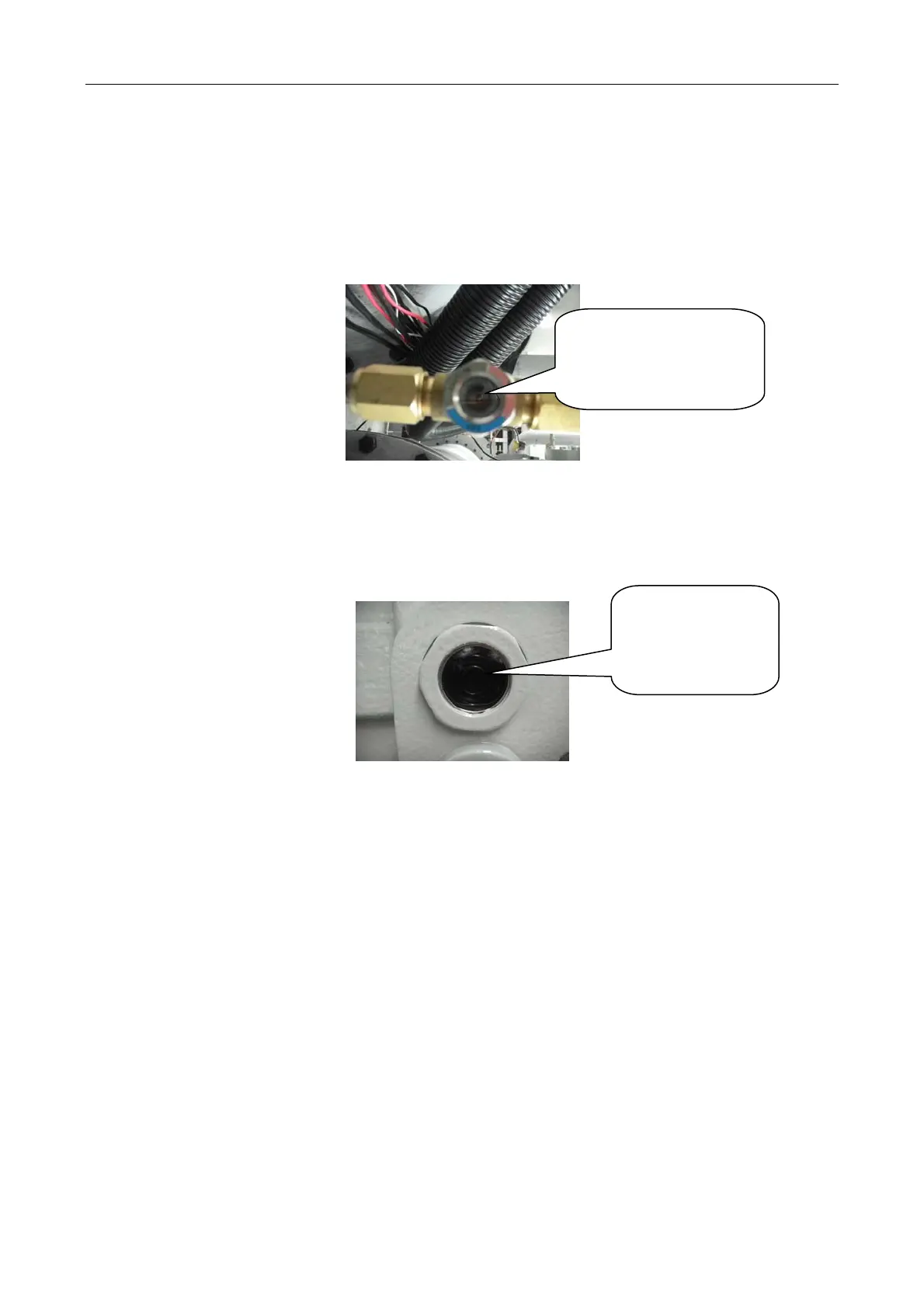

3) Sufficient lubricating oil in the oil tank (not lower than 1/2 of the oil level in the high oil

immersion lens), and no deterioration (blackness).

Inspect the oil level and quality before start-up for the two factors have direct impact on the

performance and reliability of the unit. There must be sufficient lubricating oil in the unit. And

during the shutdown of the unit, the high oil immersion lens must be full of oil.

When the unit is in stable operation, the oil level in the high oil immersion lens should be at

least above the 1/2 position. And there shall be no deterioration (blackness) of the lubricating oil,

or else, qualified lubricating oil shall be changed before operating the unit.

6) Inspect whether the pressure sensor stop valve, dry filter front/rear angle valve and liquid/air

sampling stop valve etc. are all opened.

When the unit stops, the high and low voltages shall be almost the same. After the start-up, the

low voltage decreases, and the high voltage increases. If there is no voltage change certain

time after the start-up, inspect whether the liquid/air sampling stop valve is open.

7) After the unit is installed and before connected, it is principle required to tighten the connections

in the electrical cabinet of the unit one by one.

8) Inspect the bolts of the unit for looseness.

After the unit is transported and installed, it is required to inspect whether the fixing bolts of the

unit (e.g. fixing bolts at compressor base angle, at post and beam of the unit, and at pipe clamp,

etc.) and of the electrical elements (e.g. fixing bolts of PCB and of insulating transformer, and

The oil must be full in

stop status of the

unit, and above the

1/2 position in stable

operation.

The color is indicated in the

center and compared with

the color card around it to

reflect the moistness in the

system.

Loading...

Loading...