Flooded type water cooled screw chiller (PCB Control) MCAC-CTSM-2012-11

83

outlet of both the Condenser and Evaporator and the length A of water flow switch should be 5 times

the length of the pipe diameter. Adjust the target of water flow switch according to the water pipe

specification (Refer to the manufacturing manual). Water flow switch is connected to the terminals in

control cabinet; refer to the electrical wiring diagram for details.

When power is supplied to the device, PCB control begins to detect water flow after water pumps

running for 3 minutes. If water flow switch keeps open for 5s, the chiller will stop. It needs manually

reset. Perform the steps below to solve the problem.

1. Check to confirm that all strainers are clean, valves are open and pumps are running. For the case

of VFD controlled pumps, ensure that the minimum frequency set point has not been changed.

2. Measure the pressure drop across the heat exchangers (Read the difference of pressure gauges

installed on the inlet and outlet) and using Appendix water pressure drop curves, calculate the flow

and compare this to the system requirements.

3. If the measured flow rate through the heat exchanger agrees with the system requirements.

Possible reason of the malfunction may be wrong installation direction of the switch, inadequate

depth of the target, broken switch or wiring looseness, etc. New switch must be replaced if problem is

switch itself.

5. Demand Limit

Auto unload control function

For step control unit: When compressor continuously operates at chilled water temperature > 12°C more

than 30 mins, unload to 50%; regain 100% load after 10 mins later.

For stepless control unit: When compressor continuously operates at chilled water temperature > 12°C

more than 30 mins, unload to 50%; regain 100% load after 10 mins later.

Operation current limit control

During unit running, it will unload immediately when the current reach 95% of set point and will not

execute capacity increase action. Stop unloading until compressor unloads to 50%. After unloading

operation for 10mins and the current value <=70% of set point and the unit meets loading condition, the

unit will reload step by step.

6. EXV operation& wiring

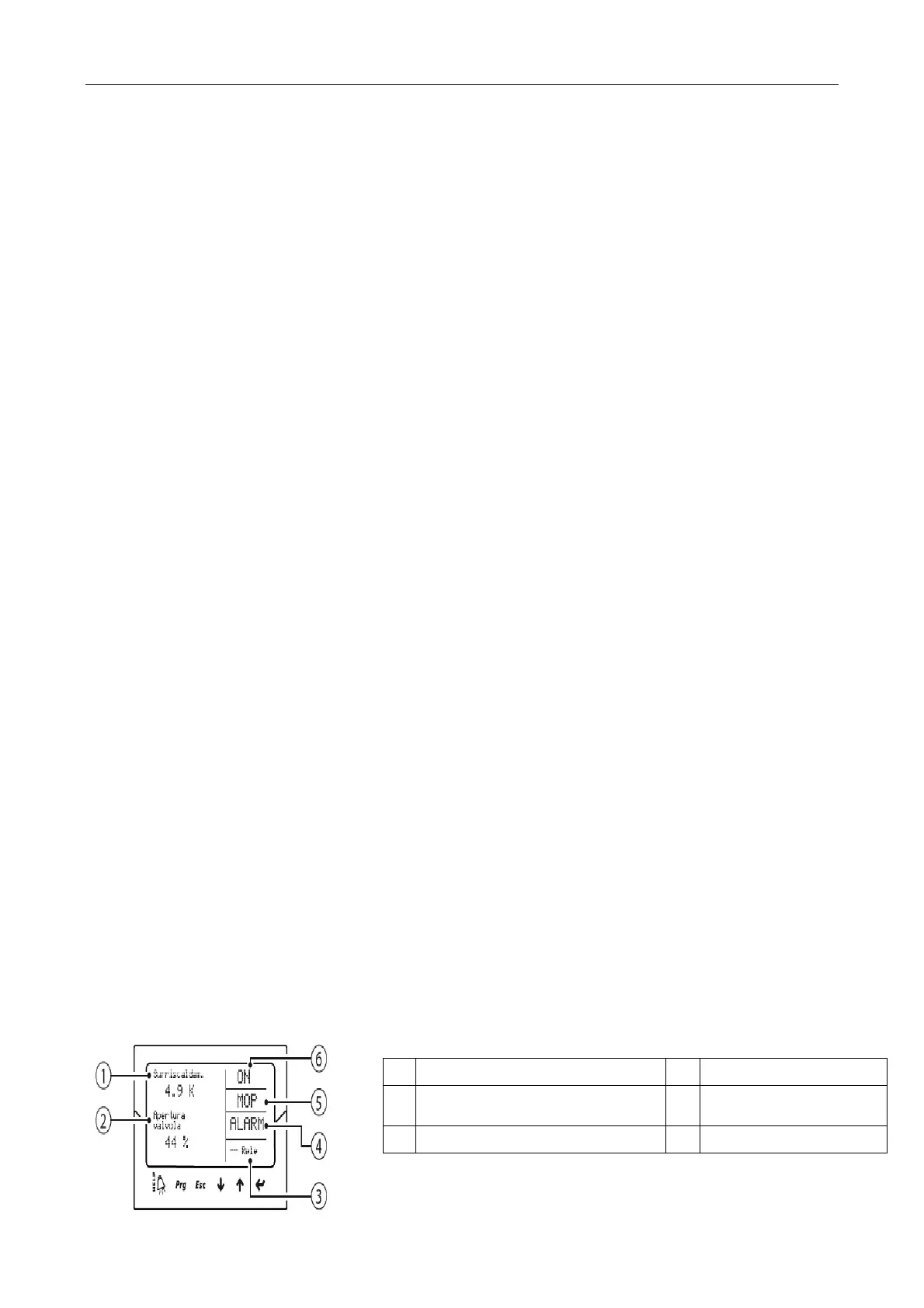

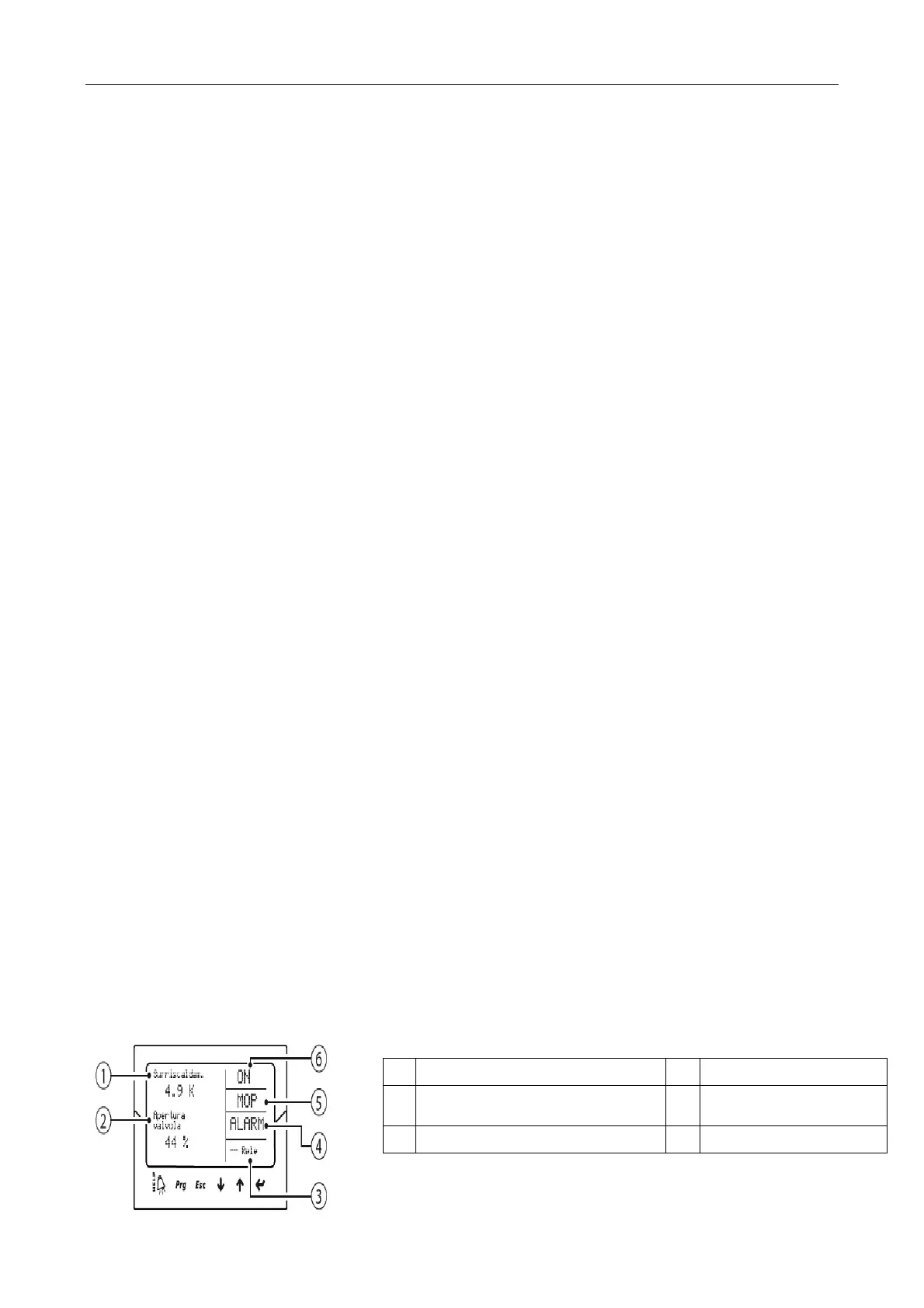

User interface consists of five components of the LED display operating status, the table below:

Display and keypad

Graphical display with two kinds of system variables, the drive control of the state, protection

function is activated, and the alarm and relay output status

1 Display first kinds of variables 4 Alarm

2

Display second kinds of

variables

5 Start of the protection

3 Relay output status 6 Control state

Loading...

Loading...