Flooded type water cooled screw chiller (PCB Control) MCAC-CTSM-2012-11

5

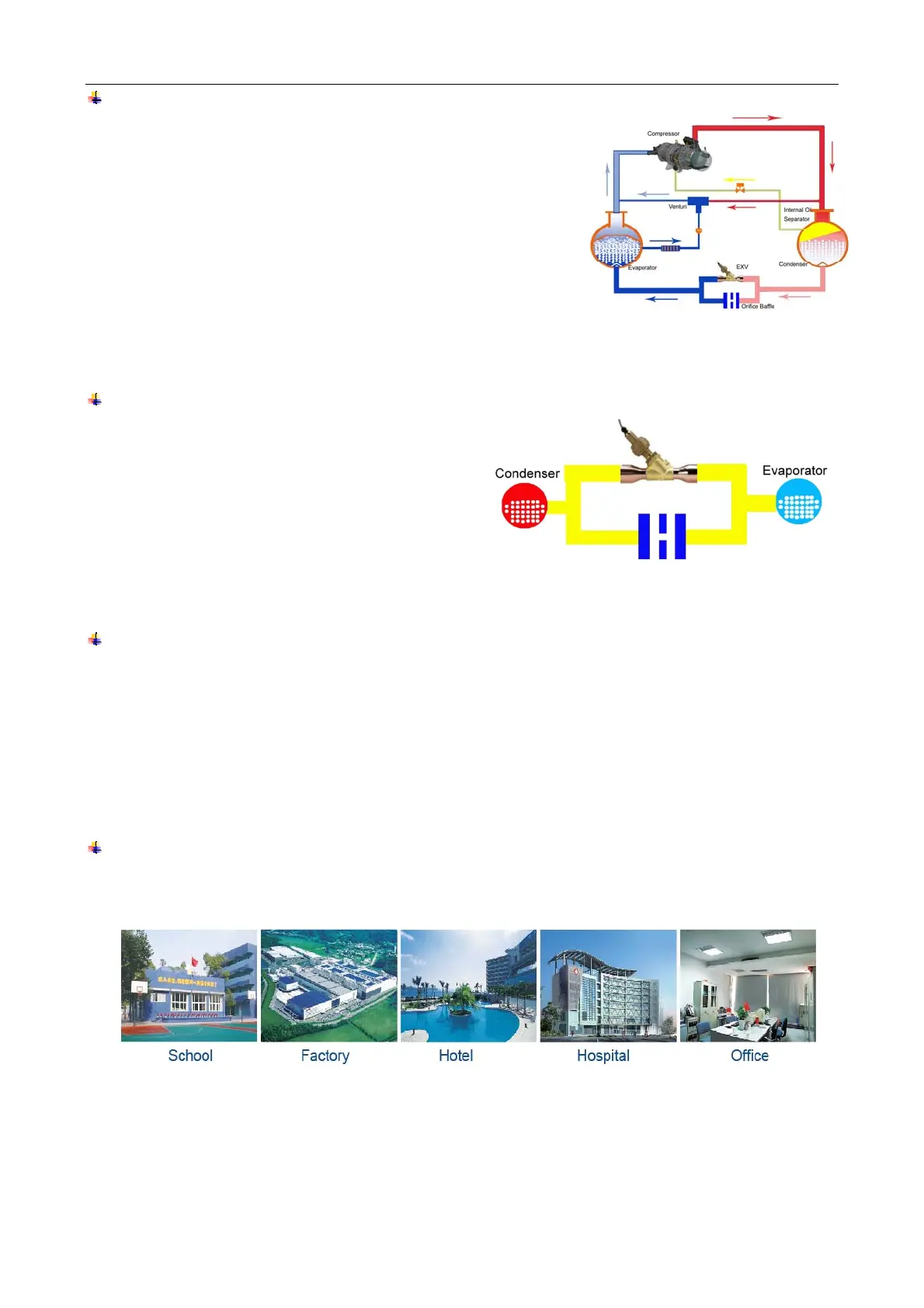

Efficient Lubrication cycle

There are two oil separators which are separately

integrated inside the compressor and condenser. The

refrigerant and oil mixture gets separated in the first oil

separator inside the compressor and then to the second oil

separator of which the separating efficiency can reach 99%. Oil

will return to compressor through the oil return pipe by

pressure difference. Some oil remains in the evaporator will be

sucked up by the Venturi tube and goes back to compressor. These two oil return circuits can

guarantee reliable oil return efficiency.

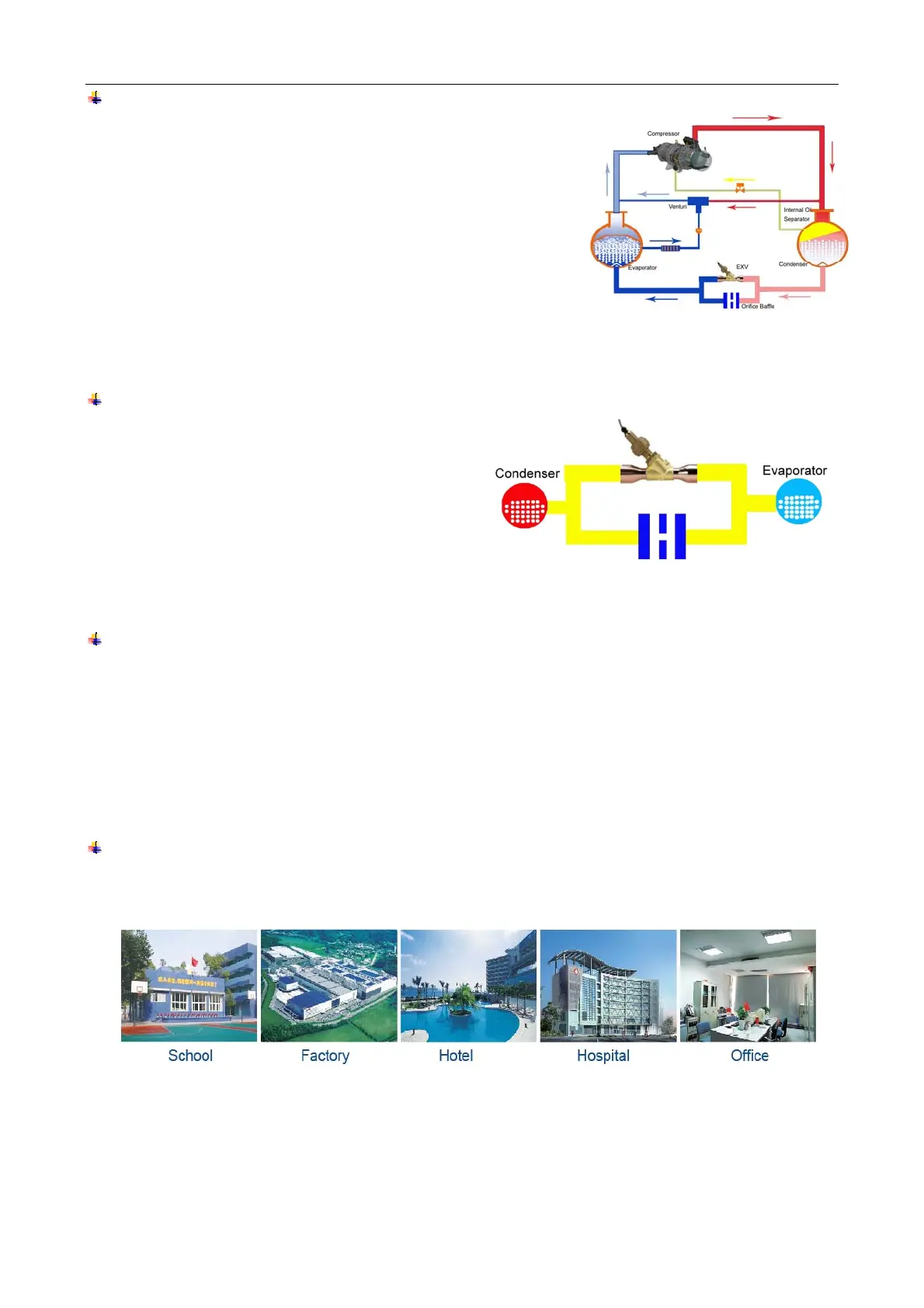

Reliable throttling device

Orifice baffle with no moving parts can

guarantee high reliability and it cooperates with

EXV(Danfoss )to throttle the high-pressure

liquid refrigerant from condenser to evaporator.

EXV which is controlled by EVD module

provides high-precision adjustment and

perfectly matches the compressor load,both full load and partial load.

Easy and fast installation

The unit has passed full factory test before being delivered to ensure the reliable working on the

site. The unit can be placed in service only after being connected with power and water supply

during field installation.

The installation and adjustment are simple .Standard flange connection and wire mesh to the

electrical panel. Refrigerant and lubrication oil are provided to the unit in the factory. Only piping

connection and power supply connection are required on the site.

Wide application range

Water cooled screw chiller are widely applied in school, hospital, shopping mall, office as well

as the factory and manufacturing processing area.

Loading...

Loading...