Flooded type water cooled screw chiller (PCB Control) MCAC-CTSM-2012-11

53

18) Measuring tape, for measuring distance and length, etc.

II. Common items and application:

1) Copper nut, incl. metric and British systems, for making connective pipe with copper pipe.

2) Gasket cardboard, for making gasket seal as sealing is frequently required during maintenance

and service.

3) PTFE tape, for tightening nut, connection, etc.

4) Insulating tape

5) Tighten strip, for tightening wire or sensor, etc.

The above are only common tools and materials. Exceptional cases require particular

considerations.

2.2 Protection items and Troubleshooting

Midea screw chiller has many protection measures and devices. There’re many features to aid in

troubleshooting. By using the alarm information, DI/O, AI/O and operating conditions of the chiller

during chiller operation, it’s convenient to find the possible problem. Verify that the chiller is properly

configured, including options and/or accessories.

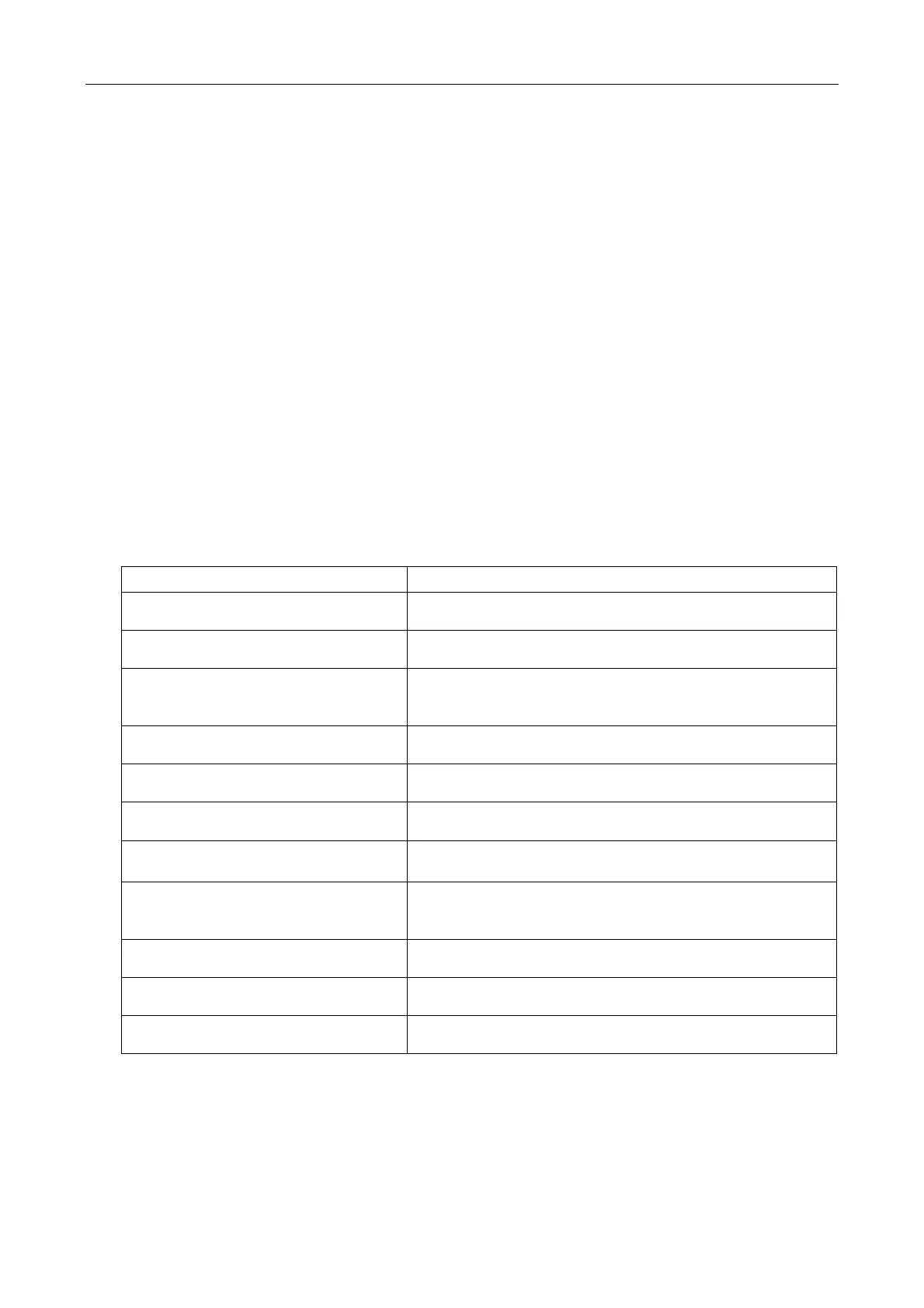

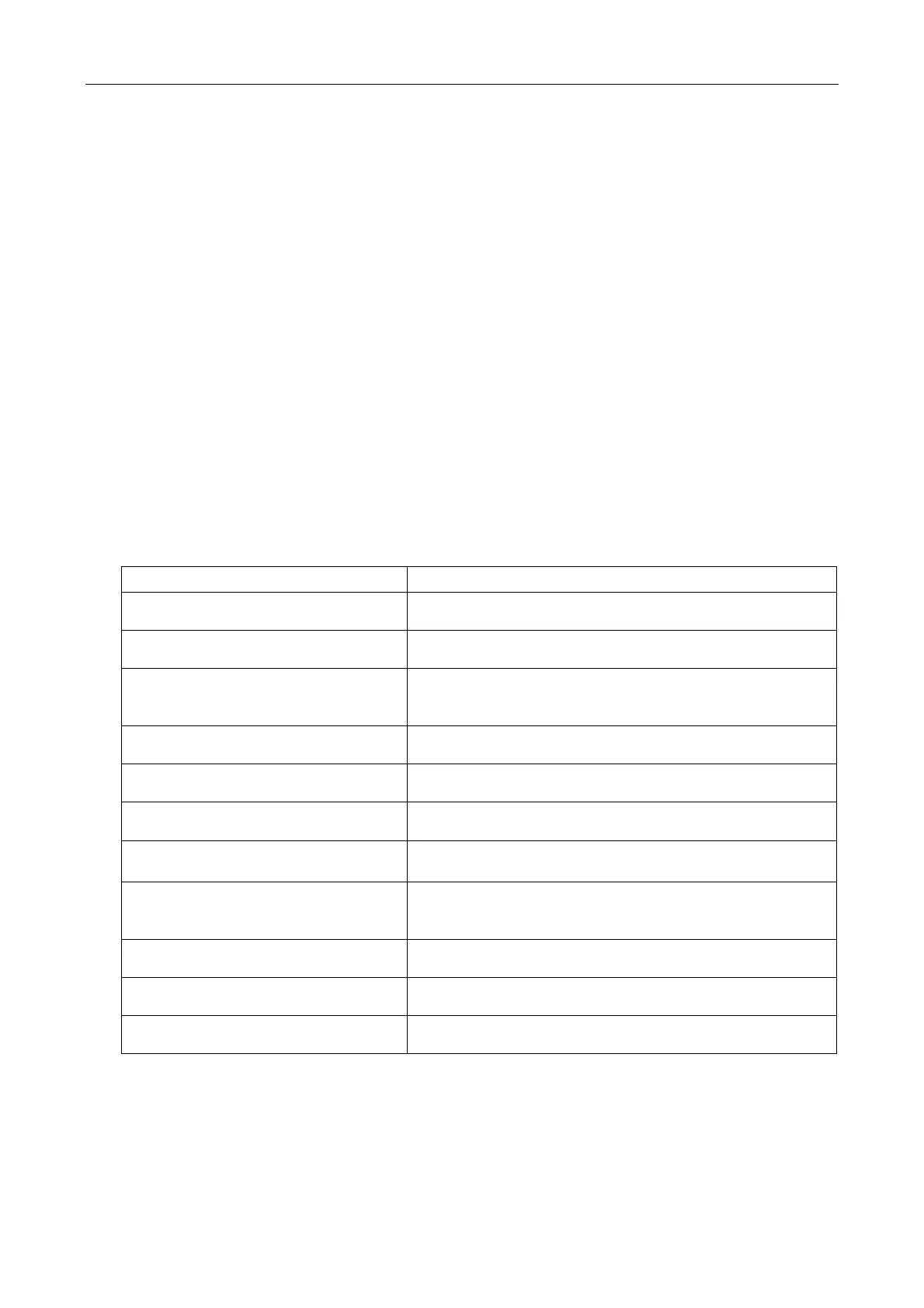

Protection items:

Protection Purpose

High pressure / low pressure

protection of compressor

Ensures the compressor runs in normal range and

ensures its work life.

Converse phase, lack of phase

protection

Protects the compressor from damage because of

converse phase or lack of phase of power.

Anti-freezing protection during

refrigeration

Protects the key components such as evaporator,

condenser and water pipe etc. from damage because of

the expanse caused by the water becomes into ice

Overload protection Protects the compressor from burn due to overload

running.

Over current protection of

compressor

Protects the compressor from burn due to over current

running under bad conditions.

Internal protection Makes the compressor run safely under permitted

conditions.

Anti-overheating protection of system Protects the compressor from burn because of running

lack of refrigerant orlubricating oil.

Water flow switch protection Protects the compressor and the water pump motor from

burn because there is lack of cooling water or chilled

water.

Protection of sensor fault Ensures the data from sensor is correct to prevent the

system from wrong action.

Oil level and oil pressure difference

protection

Ensures the compressor to run normally.

High discharge temperature

protection

Makes the compressor run safely under permitted

conditions.

Phase reversal/phase loss (phase protection)

Power supply A/B/C should exist simultaneously and differ from each other by 120° phase angle. If

not, Phase reversal or phase loss fault will occur and be displayed on screen. Before unit start when

Phase reversal or phase loss fault occurs, the chiller won’t start; when Phase reversal or phase loss

Loading...

Loading...