Flooded type water cooled screw chiller (PCB Control) MCAC-CTSM-2012-11

80

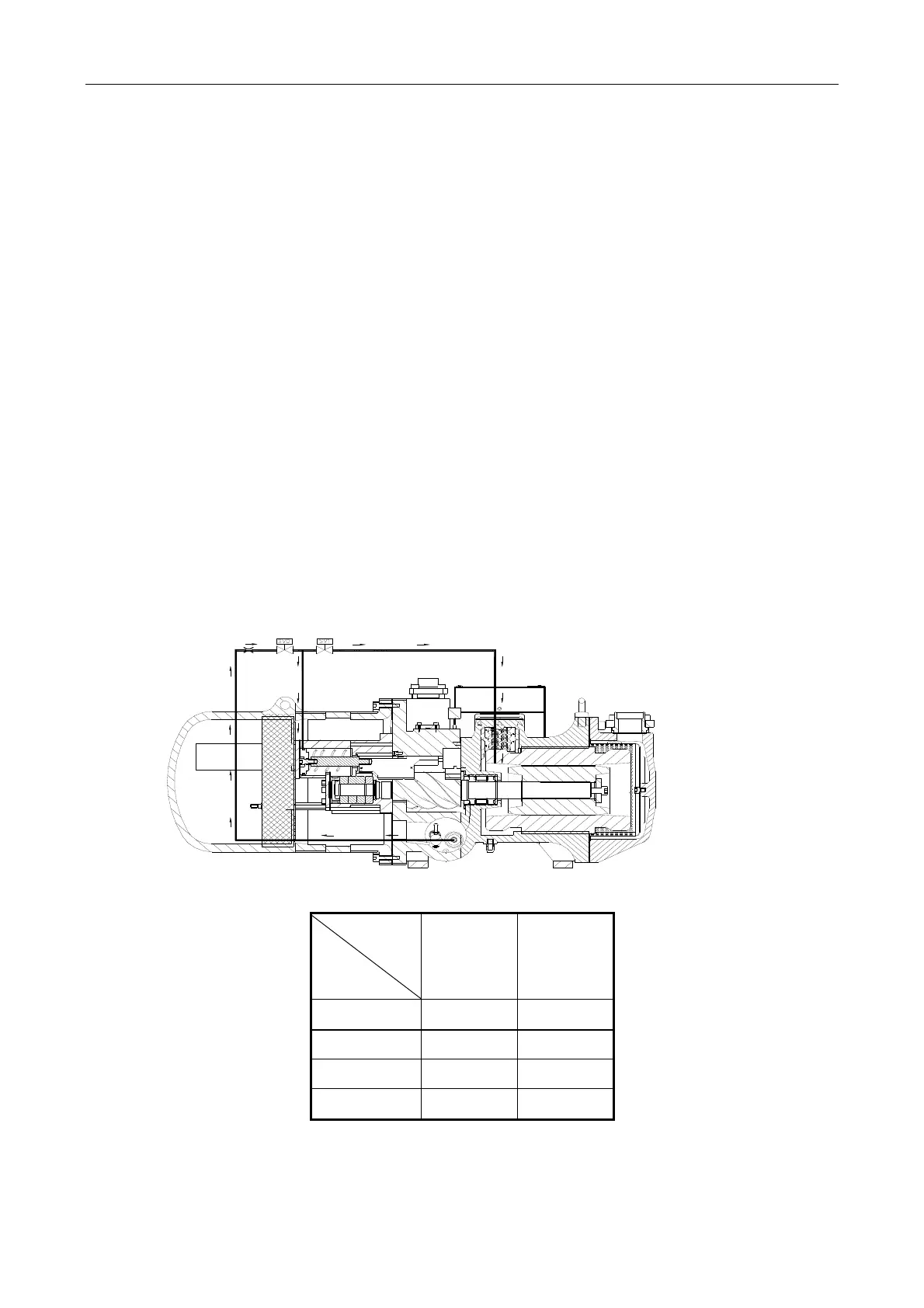

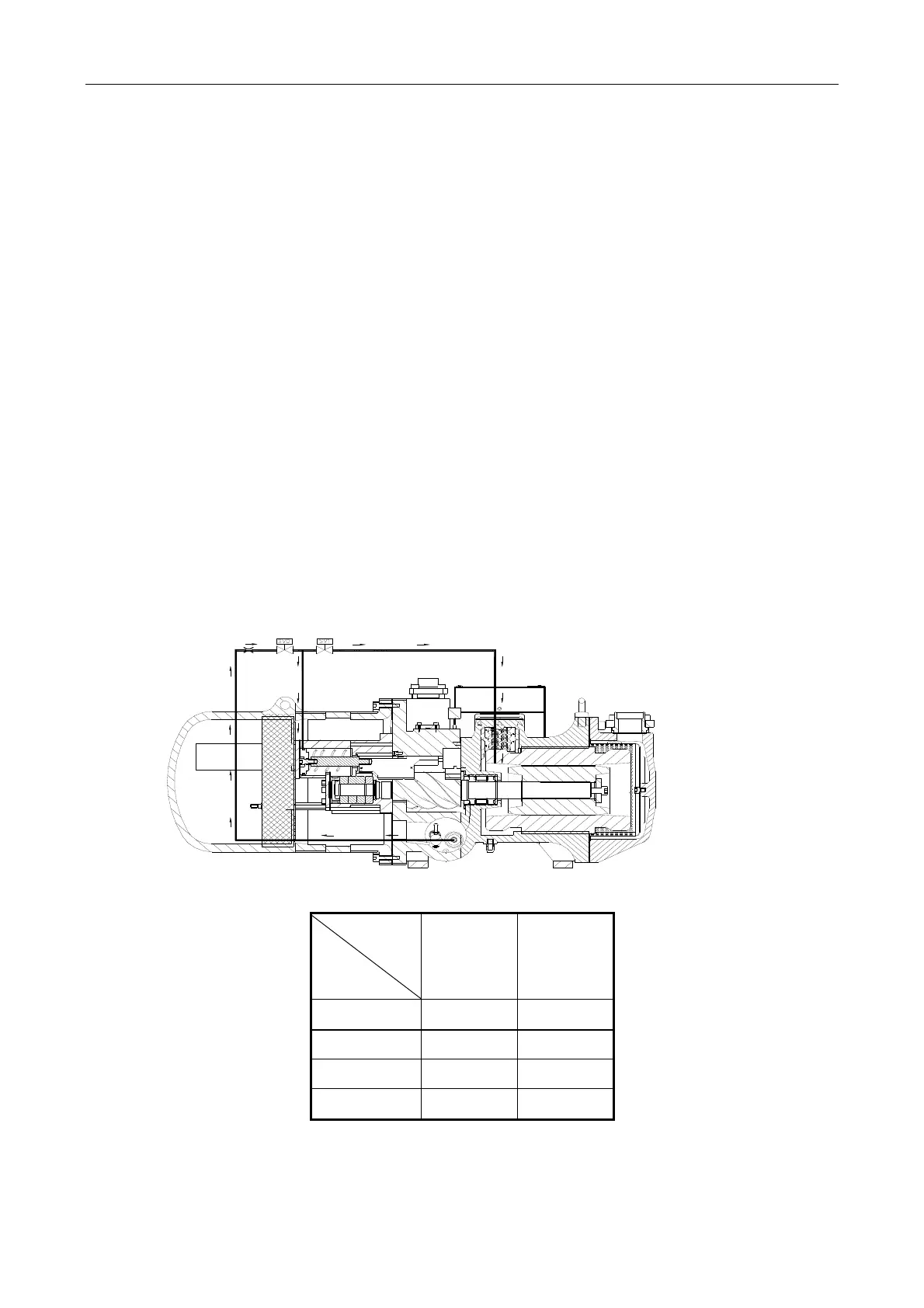

For easier startup of compressor, the loading must be minimized. Therefore, SV1 is energized to

bypass oil to the low-pressure side directly. The slider does not move and keep the maximum

opening in suction end to bypass the refrigerant. After the completion of startup the compressor then

can increase loading gradually by de-energizing the SV1 solenoid valve. It is recommended to run

compressor at 25% loading for about 30 seconds before starting to increase loading.

Partial load: 50% Operation

With the same principle as stated in 25% loading, SV2 is engergized and others are de-energized to

achieve 50% loading.

Partial load:75% Operation

Receiving a feedback from system demanding for lower capacity, the SV3 is energized to allow oil to

flow back to the low-pressure side through the valve channel. The piston returns to the outlet of SV3

oil passage and the slide block moves to let part refrigerant flow back to the low-pressure side

through bypass opening. This action would reduce the discharge volume and make the compressor

operating at 75% loading

Full load: 100% operation

After the completion of startup, SV1, SV2 and SV3 are de-energized and oil flows straight to cylinder

and pushes piston forward, driving the slider to gradually reduce bypass opening. When the

opening is closed completely, the compressor is running at 100% loading.

Stepless control (25%~50%)

Solenoid valve activating table of stepless control

SV

Status

SV0

(NC)

SV1

(NC)

Startup OFF ON

Loading ON OFF

Unloading OFF ON

Holding OFF OFF

ON: energize, OFF: de-energize

The principle of linear capacity control system is same as four-step one, except that the control logic

of solenoid valve varies. The four-step capacity-control needs three NC (normal close) solenoid

Loading...

Loading...