Aqua Tempo Super II

201709 83

Part

4 - Diagnosis and Troubleshooting

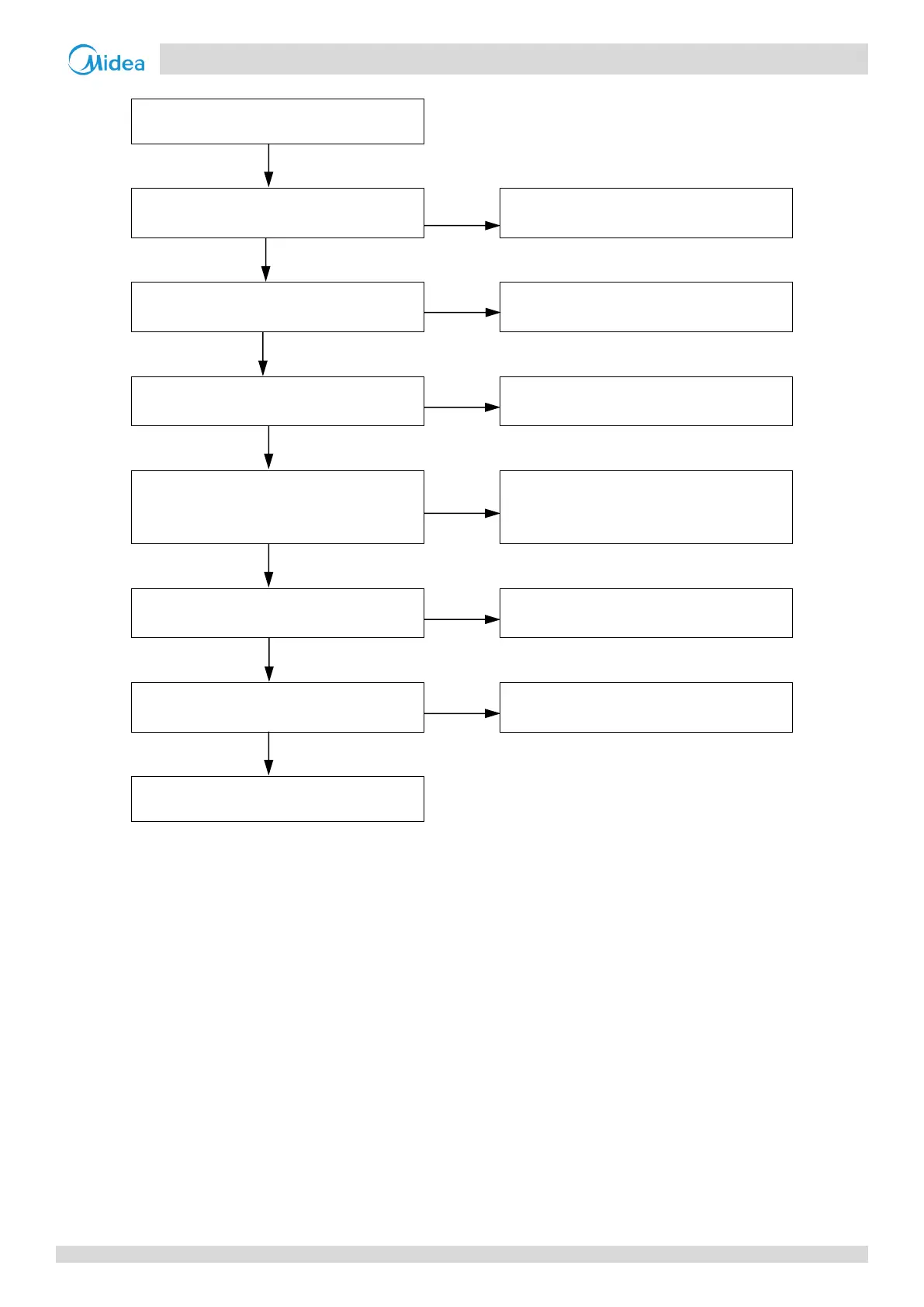

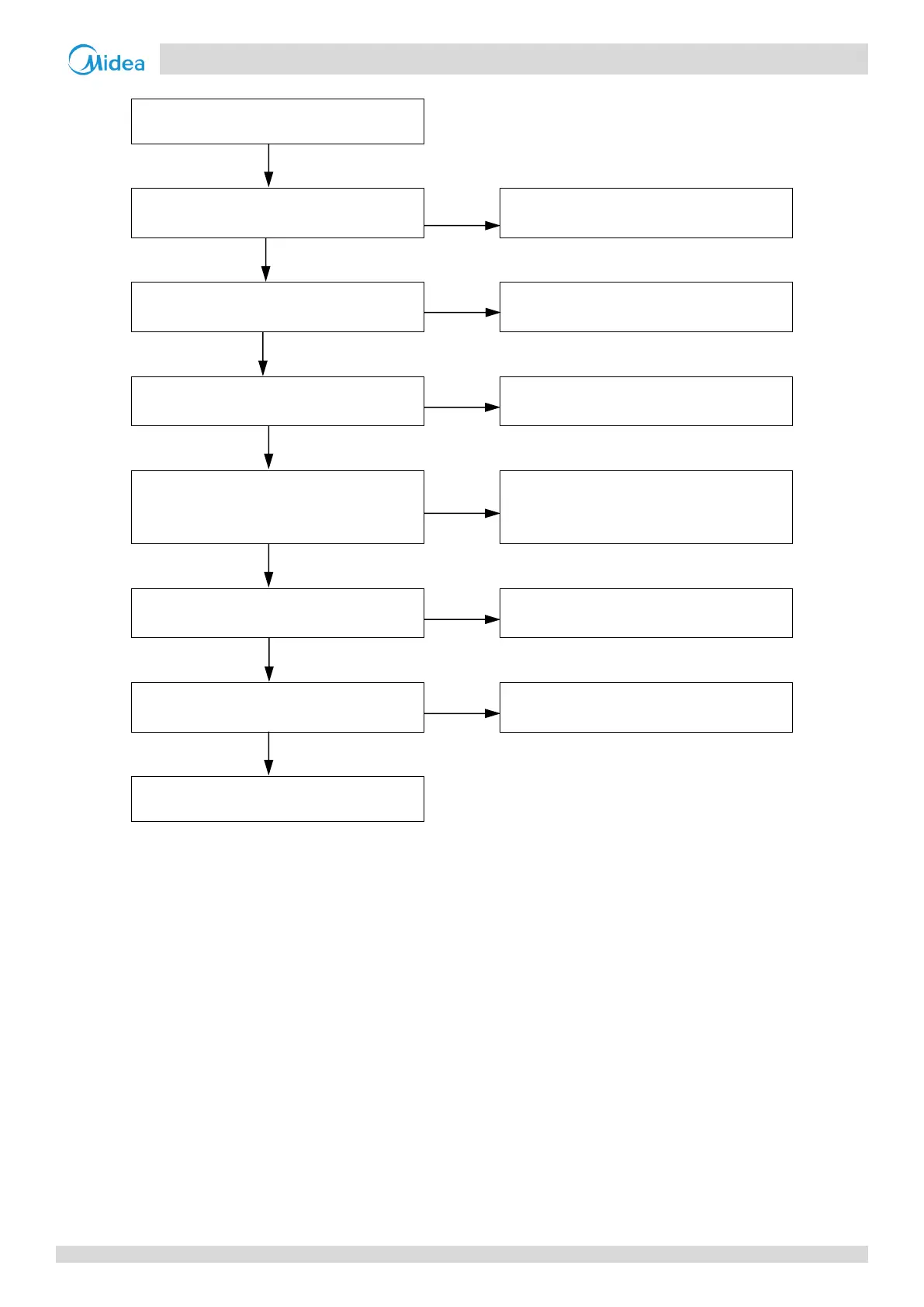

Procedure 4.16.4

Low pressure sensor connection on main

PCB is loose

1

Ensure the sensor is connected properly

Low pressure sensor has short-circuited

or failed

2

Insufficient refrigerant caused by

refrigerant leakage

3

Add refrigerant or inspect the system for

leaks

The low pressure side is blocked, caused

by crushed or bent pipe, blocked EXV, or

dirty filter

4

Inspect the system and fix the error. If the

filter is blocked by ice, the piping should

be cleaned

The air side heat exchanger heat

exchange is poor in heating mode

5

Inspect the refrigerant system and fix the

error

The water flow rate is not sufficient in

cooling mode

6

Inspect the water system and fix the

error

Notes:

1. Low pressure sensor connection is port CN40 on the main PCB (labeled 25 in Figure 4-2.1 in Part 4, 2.2 “Outdoor unit main PCB”) .

2. Measure the resistance among the three terminals of the pressure sensor. If the resistance is of the order of mega Ohms or infinite, the pressure sensor

has failed.

3. To check for insufficient refrigerant: An insufficiency of refrigerant causes compressor discharge temperature to be higher than normal, discharge and

suction pressures to be lower than normal and compressor current to be lower than normal, and may cause frosting to occur on the suction pipe. These

issues disappear once sufficient refrigerant has been charged into the system.

4. A low pressure side blockage causes compressor discharge temperature to be higher than normal, suction pressure to be lower than normal and

compressor current to be lower than normal, and may cause frosting to occur on the suction pipe. For normal system parameters.

5. Check air side heat exchanger, fan(s) and air outlets for dirt/blockages.

6. Check water side heat exchanger, water piping, circulator pumps and water flow switch for dirt/blockages.

Loading...

Loading...