The unit is only to be used in a closed water system.

Application in an open water circuit can lead to excessive

corrosion of the water piping.

When water is not moving inside the system in cold

weather, freezing is very likely and will damage

the system.

Checking the water circuit

The units are equipped with a water inlet and outlet for connection

to a water circuit. This circuit must be provided by a licensed technician

and must comply with local laws and regulations.

Checking the water volume and expansion vessel pre-pressure

The unit is equipped with a 5 L(for 5/7/9 kW unit, the volume is 2L)

expansion vessel that has a default pre-pressure of 1.5 bar.

To assure proper operation of the unit, the pre-pressure of the expansion

vessel might need to be adjusted and the minimum and maximum water

volume must be checked.

1. Check that the total water volume in the installation, excluding the

internal water volume of the unit, is at least 25L(for 5/7/9 kW unit,

the minimum volume is 15L) . Refer to 14 Technical specifications

to find the total internal water volume of the unit.

Before continuing installation of the unit, check the following:

■ The maximum water pressure = 3 bar.

■ The maximum water temperature is 70°C according to safety

device setting.

■ Always use materials that are compatible with the water used in the

system and with the materials used in the unit.

■ Ensure that components installed in the field piping can withstand

the water pressure and temperature.

■ Drain taps must be provided at all low points of the system to

permit complete drainage of the circuit during maintenance.

■ Air vents must be provided at all high points of the system. The

vents should be located at points that are easily accessible for

servicing. An automatic air purge is provided inside the unit. Check

that this air purge valve is not tightened too much so that automatic

release of air in the water circuit remains possible.

A

<A

9.3 Water pipework

All piping lengths and distances have been taken into consideration.

Requirements

Valve

The maximum allowed thermistor cable length is 20m.

This is the maximum allowable distance between the

domestic hot water tank and the unit (only for

installations with a domestic hot water tank).The

thermistor cable supplied with the domestic hot water

tank is 10m in length.

In order to optimize efficiency we recommend installing

the 3-way valve and the domestic hot water tank as

close as possible to the unit

Thermistor

cable

length

minus 2m

NOTE

■ In most applications this minimum water volume will be

satisfactory.

■ In critical processes or in rooms with a high heat load though,

extra water might be required.

■ When circulation in each space heating loop is controlled by

remotely controlled valves, it is important that this minimum

water volume is kept even if all the valves are closed.

NOTE

■ If the installation is equipped with a domestic hot water tank

(optional), please refer to the domestic hot water tank

Installation & Owner's Manual.

■ If there is no glycol (anti-freeze) in the system there is a power

supply or pump failure, drain the system (as shown in the figure

below).

26

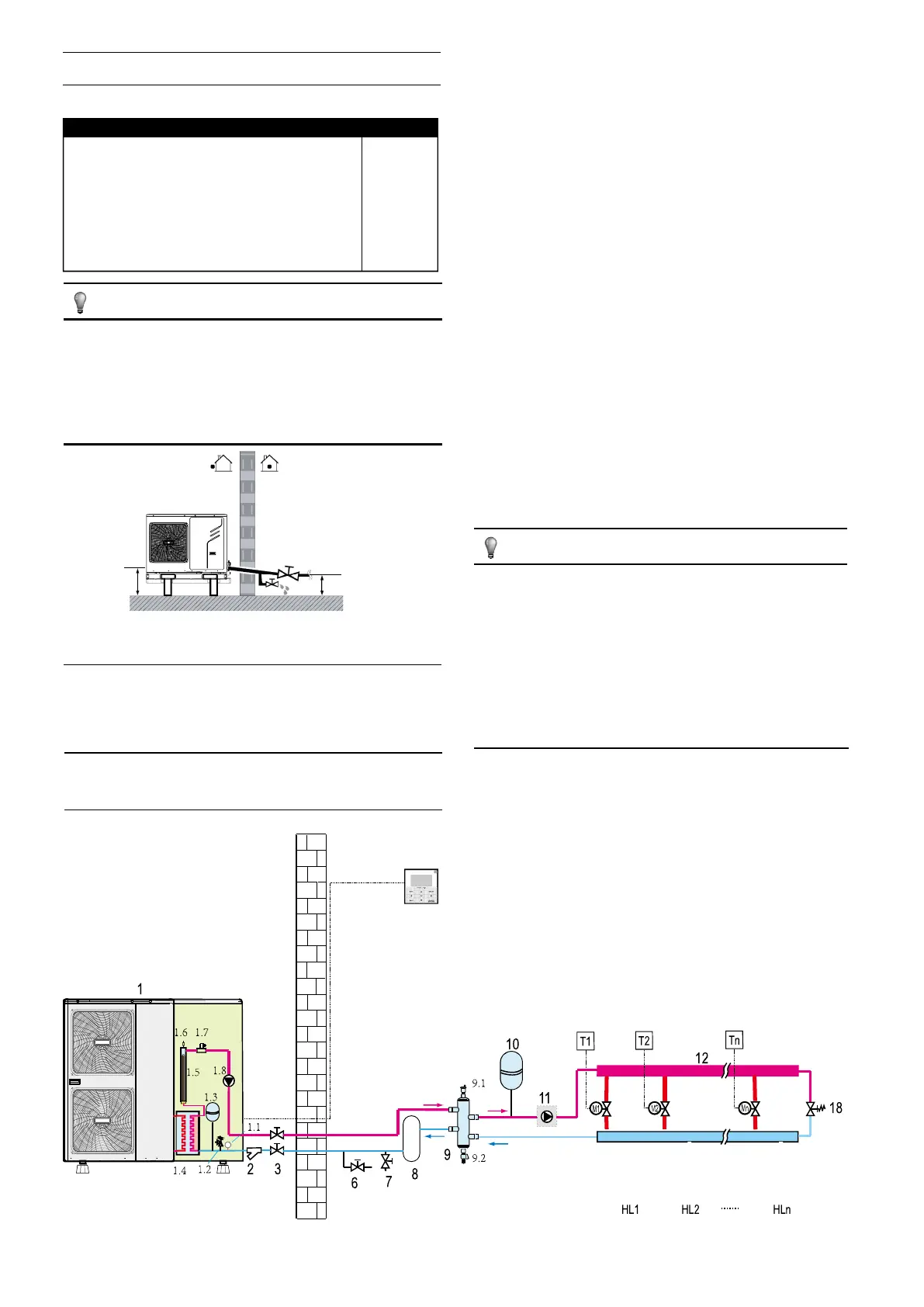

Example

1 Outdoor Unit

1.1 Manometer

1.2 Pressure Relief Valve

1.3 Expansion Vessel

1.4 Plate Heat Exchanger

1.5 Backup Heater

1.6 Air Purge Valve

1.7 Flow Switch

1.8 P_i: Circulation Pump Inside Unit

2 Y-shape Filter

3 Stop Valve (Field Supply)

4 User Interface

6 Drain Valve(Field Supply)

7 Fill Valve(Field Supply)

8 Buffer Tank(Field Supply)

9 Balance Tank(Field Supply)

9.1 Air Purge Valve

9.2 Drain Valve

10 Expansion Vessel (Field

Supply)

11 P_o: Outside Circulation Pump

(Field Supply)

12 Collector(Field Supply)

18 Bypass Valve(Field Supply)

Fhl 1...N Floor Heating Loop

M1...N Motorized Valve (Field

Supply)

T1…n Room Thermostat (Field

Supply)

Loading...

Loading...