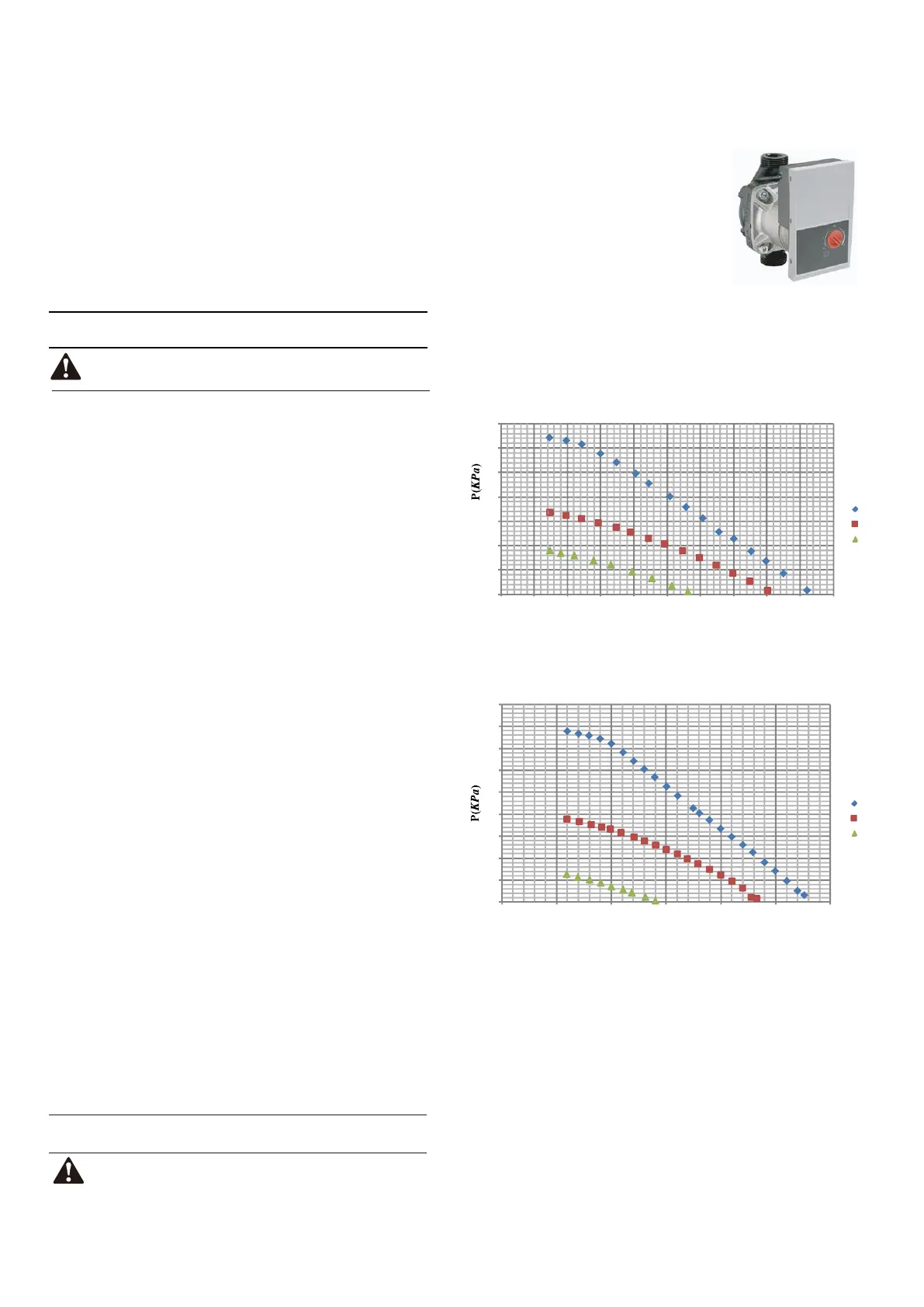

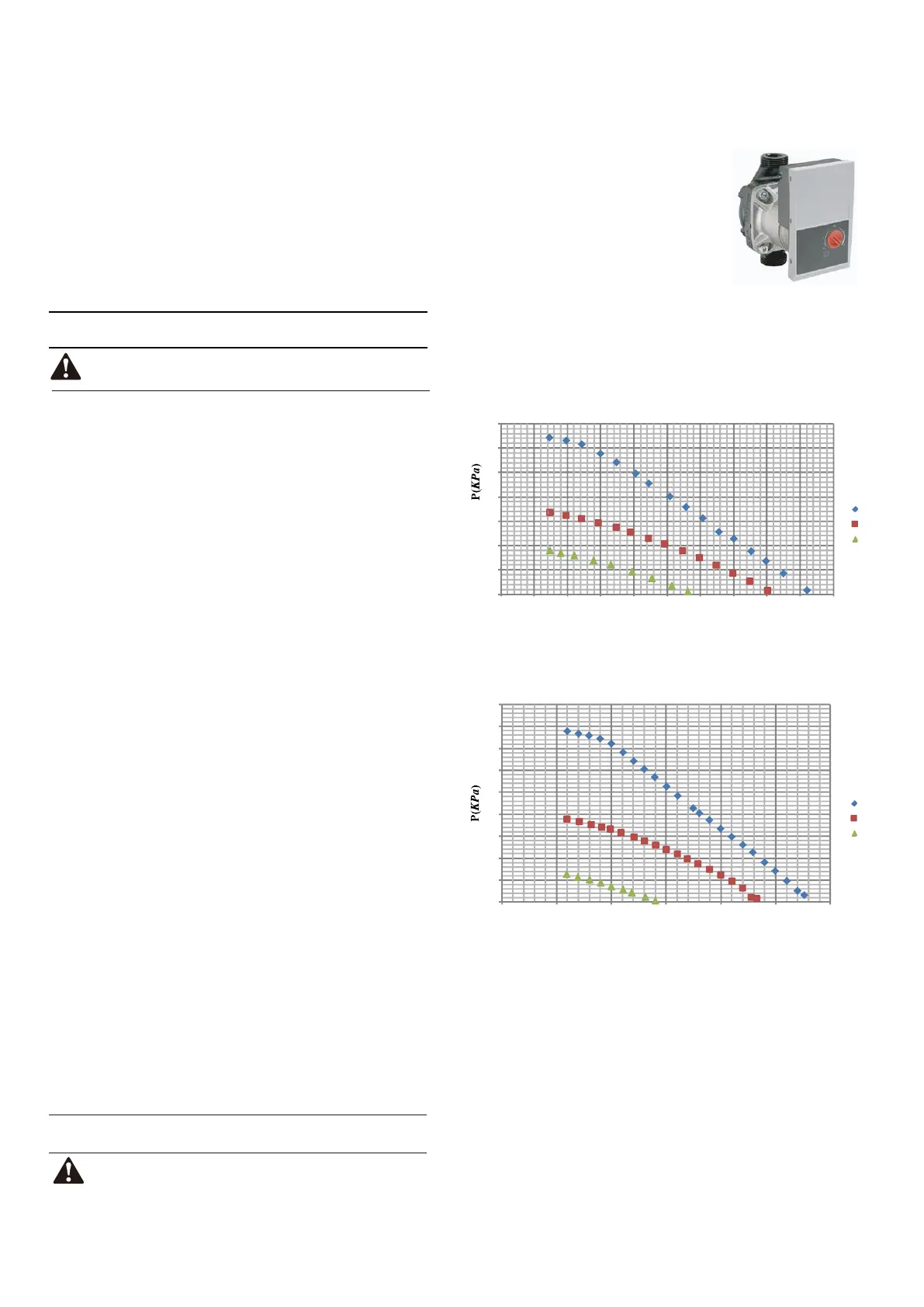

The available external static pressure function for water flow is

shown in the graph below.

10.6 Setting the pump speed

The default setting is the highest speed (III).

If the water flow in the system is too high

the speed can be

set to low (I).

The pump speed can be selected by

adjusting the red knob on the pump. The

notch point indicates pump speed.

5. Ground wiring

Make sure that the ground wires have been connected properly

and that the ground terminals are tightened.

6. Internal wiring

Visually check the switch box for loose connections or damaged

electrical components.

7. Mounting

Check that the unit is properly mounted, to avoid abnormal noises

and vibrations when starting up the unit.

8. Damaged equipment

Check the inside of the unit for damaged components or

squeezed pipes.

9. Refrigerant leak

Check the inside of the unit for refrigerant leakage. If there is a

refrigerant leak, call your local dealer.

10.Power supply voltage

Check the power supply voltage on the local supply panel. The

voltage must correspond to the voltage on the identification label

of the unit.

11.Air purge valve

Make sure the air purge valve is open (at least 2 turns).

2. Fuses, circuit breakers, or protection devices

Check that the fuses or the locally installed protection devices are

of the size and type specified in the chapter 14 Technical

specifications. Make sure that no fuses or protection devices

have been bypassed.

3. Backup heater circuit breaker

Do not forget to turn on the backup heater circuit breaker in the

switchbox (it depends on the backup heater type). Refer to the

wiring diagram.

4. Booster heater circuit breaker

Do not forget to turn on the booster heater circuit breaker (applies

only to units with optional domestic hot water tank installed).

10.5 Powering up the unit

Operating the system with closed valves will damage the

circulation pump!

12.Shut-off valves

Make sure that the shut-off valves are fully open

When power to the unit is turned on, "1%~99%" is displayed on the

user interface during initialization. During this process the user

interface cannot be operated.

0

10

20

30

40

50

60

70

80

90

0.3 0.8 1.3 1.8 2.3 2.8 3.3

Flowrate(m³/h)

available external stac pressure VS flowrate

(1-phase 10-16kW + 3-phase 12~16kW)

Ⅲ

Ⅱ

Ⅰ

0

10

20

30

40

50

60

70

0.3 0.5 0.7 0.9 1.1 1.3 1.5 1.7 1.9 2.1 2.3

Flowrate(m³/h)

available external stac pressure VS flowrate

(5/7/9kW)

Ⅲ

Ⅱ

Ⅰ

Checks before initial start-up

10.4 Pre-operation checks

10.3 Initial start-up at low outdoor ambient temperatures

During initial start-up and when water temperature is low, it is

important that the water is heated gradually. Failure to do so may

result in concrete floors cracking due to rapid temperature change.

Please contact the responsible cast concrete building contractor for

further details.

To do so, the lowest water flow set temperature can be decreased to

a value between 25°C and 35°C by adjusting the FOR SERVICEMAN.

Refer to "FOR SERVICEMAN/special function/preheating for floor" .

Switch off the power supply before making any connections.

DANGER

After the installation of the unit, check the following before switching

on the circuit breaker:

1. Field wiring

Make sure that the field wiring between the local supply panel and

unit and valves (when applicable), unit and room thermostat (when

applicable), unit and domestic hot water tank, and unit and backup

heater box have been connected according to the instructions

described in the chapter 9.6 Field wiring, according to the wiring

diagrams and to local laws and regulations.

38

38

Loading...

Loading...