NOTE

The unit is only to be used in a closed water system. Application in

an open water circuit can lead to excessive corrosion of the water

piping:

■ Never use Zn-coated parts in the water circuit. Excessive

corrosion of these parts may occur as copper piping is used in

the unit's internal water circuit.

■ When using a 3-way valve in the water circuit. Preferably

choose a ball type 3-way valve to guarantee full separation

between the domestic hot water and floor heating water circuit.

■ When using a 3-way valve or a 2-way valve in the water circuit.

The recommended maximum changeover time of the valve

should be less than 60 seconds.

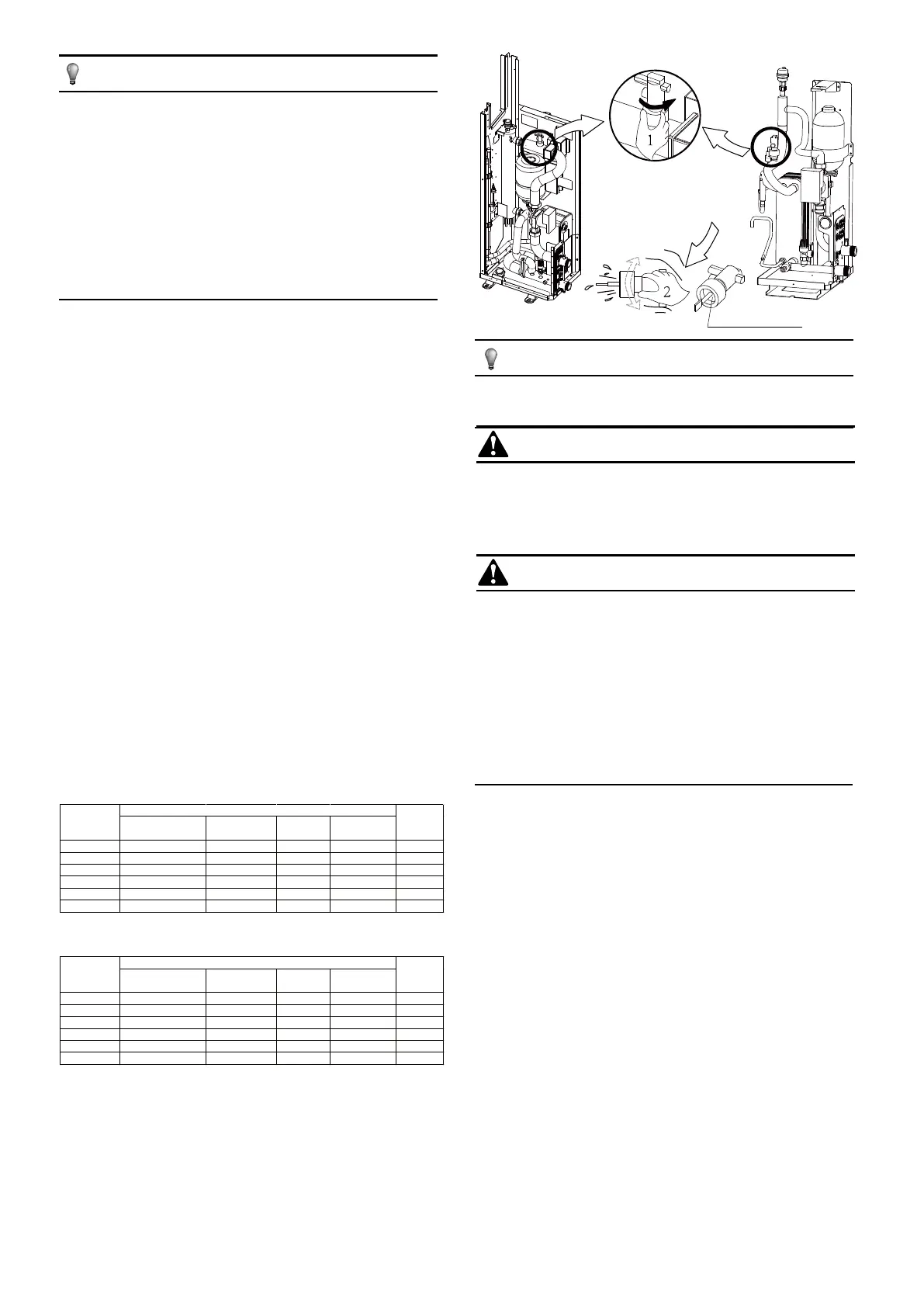

NOTE

■ CounterclockWise rotation, remove the flow switch.

■ Drying the flow switch completely.

WARNING

(a) ETHYLENE GLYCOL IS TOXIC

The concentrations mentioned in the table above will not prevent

freezing, but will prevent the hydraulics from bursting.

CAUTION

Use of glycol

■ Glycol use for installations with a domestic hot water tank:

- Only propylene glycol having a toxicity rating or class of 1, as

listed in "Clinical Toxicology of Commercial Products, 5th edition"

may be used.

The maximum allowed water volume is then reduced according to

the figure “Maximum allowed water volume” on page 27.

■ If there is too much pressure when using glycol, connect the

safety valve to a drain pan to recover the glycol.

Corrosion in the system due to glycol

Uninhibited glycol will turn acidic under the influence of oxygen. This

process is accelerated by presence of copper and at higher

temperatures. The acidic uninhibited glycol attacks metal surfaces

and forms galvanic corrosion cells that cause severe damage to the

system.

It is of extreme importance:

■ That the water treatment is correctly executed by a qualified water

specialist.

■ That a glycol with corrosion inhibitors is selected to counteract

acids formed by the oxidation of glycols.

■ That in case of an installation with a domestic hot water tank, only

the use of propylene glycol is allowed. In other installations the

use of ethylene glycol is fine.

■ That no automotive glycol is used because their corrosion

inhibitors have a limited lifetime and contain silicates that can foul

or plug the system;

■ That galvanized piping is not used in glycol systems since it may

lead to the precipitation of certain elements in the glycol’s

corrosion inhibitor;

■ To ensure that the glycol is compatible with the materials used in

the system.

28

There need drying

Protecting the water circuit against freezing

Frost can cause damage to the hydraulic system. As this unit is

installed outdoors and thus the hydraulic system is exposed to

freezing temperatures, care must be taken to prevent freezing of the

system.

All hydraulic parts are insulated to reduce heat loss. Insulation must

be present on the field piping.

The unit is already equipped with several features to prevent

freezing.

■ The software contains special functions using the heat pump to

protect the entire system against freezing.

When the temperature of the water flow in the system drops to a

certain value, the unit will heat the water, either using the heat

pump, the electric heating tap, or the backup heater. The freeze

protection function will turn off only when the temperature increases

to a certain value.

In case of a power failure, the features mentioned above cannot

protect the unit from freezing.

Since a power failure could happen when the unit is unattended,

the supplier recommends adding glycol to the water system. Refer

to “Caution: Use of glycol” .

Depending on the expected lowest outdoor temperature, make sure

the water system is filled with a concentration of glycol as mentioned

in the table below.

Water may enter into the flow switch and cannot be drained out and

may freeze when the temperature is low enough. The flow switch

should be removed and dried, then can be reinstalled in the unit.

When glycol is added to the system, the performance of the unit will

be affected. The correction factor of the unit capacity, flow rate and

pressure drop of the system is listed in the table below

If no glycol is added, the water must be drained out when there is a

power failure.

Ethylene Glycol

Propylene Glycol

Cooling capacity

modification

Power

modification

Water

resistanc

Water flow

modification

0 1.000 1.000 1.000 1.000 0.000

10 0.984 0.998 1.118 1.019 -4.000

20 0.973 0.995 1.268 1.051 -9.000

30 0.965 0.992 1.482 1.092 -16.000

40 0.960 0.989 1.791 1.145 -23.000

50 0.950 0.983 2.100 1.200 -37.000

0 1.000 1.000 1.000 1.000 0.000

10 0.976 0.996 1.071 1.000 -3.000

20 0.961 0.992 1.189 1.016 -7.000

30 0.948 0.988 1.380 1.034 -13.000

40 0.938 0.984 1.728 1.078 -22.000

50 0.925 0.975 2.150 1.125 -35.000

Modification coefficient

Quality of

glycol/%

Freezing

point/℃

Modification coefficient

Cooling capacity

modification

Power

modification

Water

resistanc

Water flow

modification

Quality of

glycol/%

Freezing

point/℃

Loading...

Loading...