34

Procedure

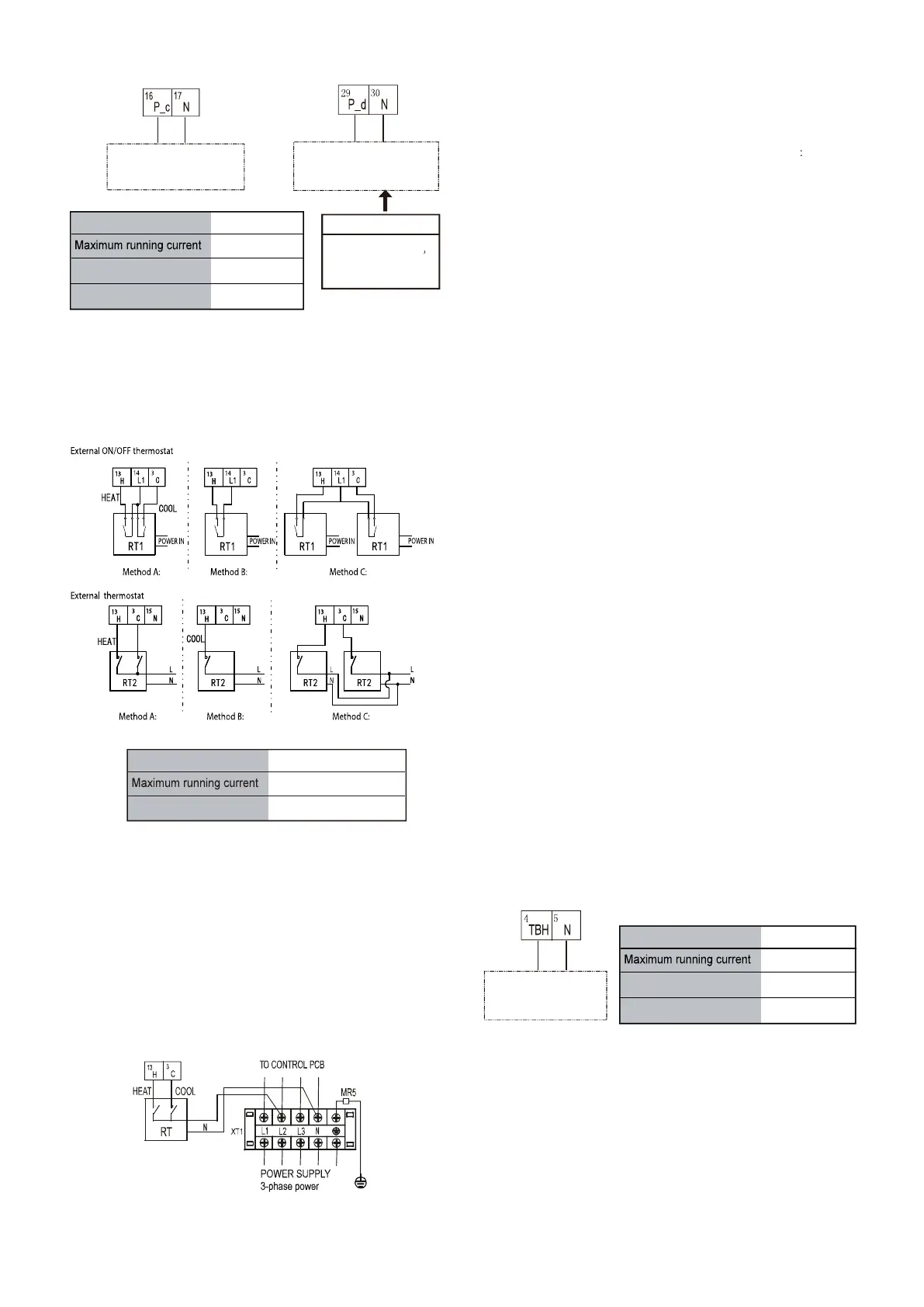

1. Connect the cable to the appropriate terminals as shown in the

picture.

2. Fix the cable with cable ties to the cable tie mountings to ensure

stress relief

For room thermostat:

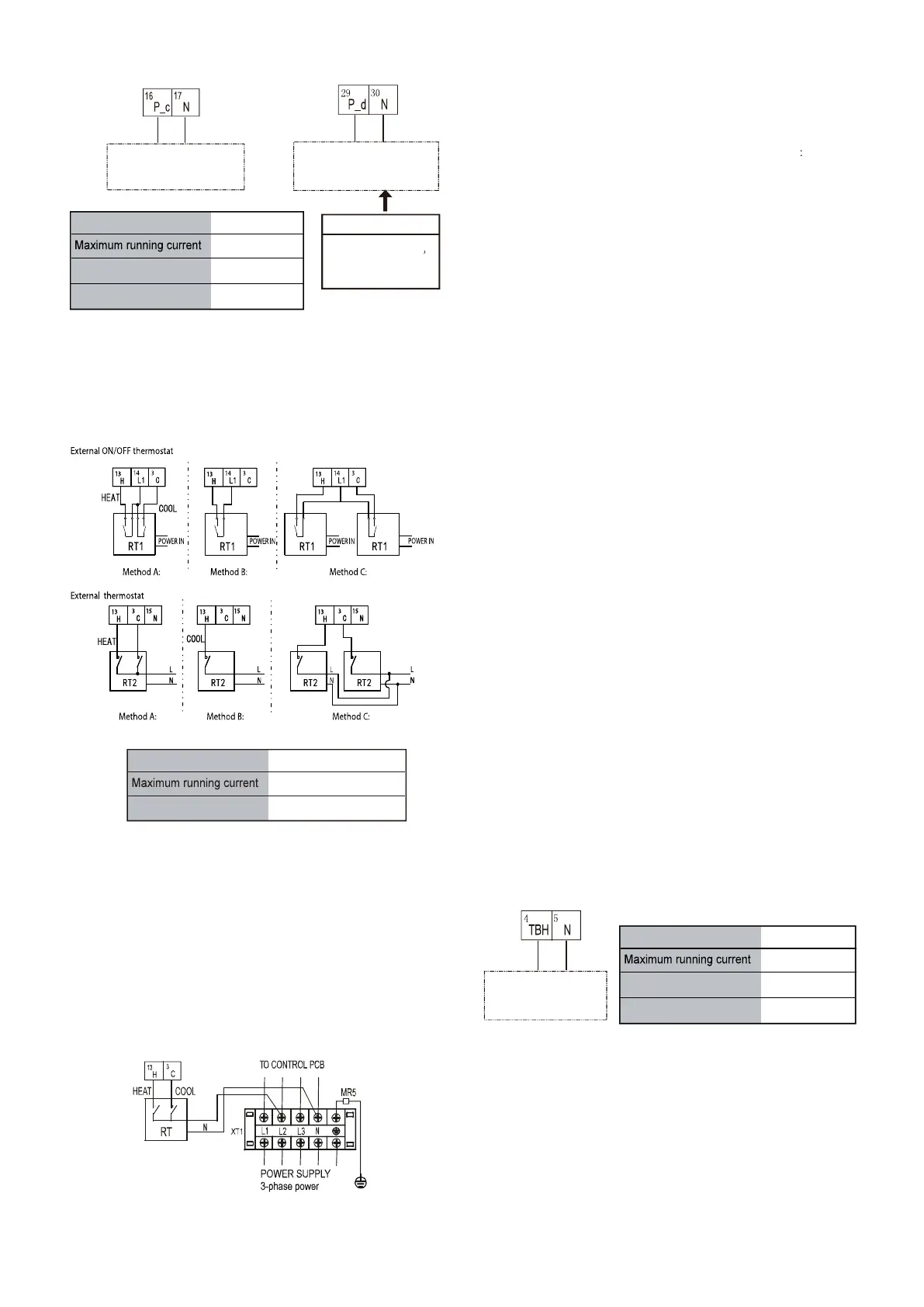

For booster heater:

For tank loop pump P_d and mix pump P_c:

Connection of the booster heater cable depends on the application.

Only when the domestic hot water tank is installed will this wiring be

needed. The unit only sends a turn on/off signal to the booster heater.

An additional circuit breaker is needed and a dedicated terminal is

needed to supply power to the booster heater.

See also "8 Typical application examples" and "10.7 Field

settings/DHW control” for more information.

PUMPC

CONTROL SIGNAL OUTPUT

PUMPD

CONTROL SIGNAL OUTPUT

TANK BOOST HEATER

CONTROL SIGNAL

OUTPUT

For 5/7/9 kW unit

the terminal number

is 37 and 38.

NOTE

0.2A

Wiring size

Voltage 220-240VAC

0.75mm

2

Note:

there are two optional connect method depend on the room

thermostat type.

1. Room thermostat type 1(RT1): “POWER IN” provide the working

voltage to the RT, doesn’t provide the voltage to the RT connector

directly. Port “14 L1” provide the 220V voltage to the RT connector.

Port “14 L1” connect from the unit main power supply port L of 1-

phase power supply, L2 port of 3-phase power supply.

Method A

RT can control heating and cooling individually, like the controller for

4-pipe FCU. When the hydraulic module is connected with the

external temperature controller, user interface FOR SERVICEMAN

set THERMOSTAT and ROOM MODE SETTING to YES

A.1 When unit detect voltage is 230VAC between C and N ,the unit

operates in the cooling mode

A.2 When unit detect voltage is 230VAC between H and N, the unit

operates in the heating mode.

A.3 When unit detect voltage is 0VAC for both side(L-N, H-N) the unit

stop working for space heating or cooling.

A.4 When unit detect voltage is 230VAC for both side(L-N, H-N) the

unit working in cooling mode.

Method B

RT provide the switch signal to unit. user interface FOR

SERVICEMAN set ROOM THERMOSTAT and MODE SETTING to

YES:

B.1 When unit detect voltage is 230VAC between H and N, unit turn

on.

B.2 When unit detect voltage is 0VAC between H and N, unit turn off.

Note:When ROOM THERMOSTAT is set to YES, the indoor

temperature sensor Ta can’t be set to valid, unit running only according

to T1.

Method C

Hydraulic module is connected with two external temperature

controllers, while user interface FOR SERVICEMAN set DUAL

ROOM THERMOSTAT to YES,

C.1 When unit detect voltage is 230VAC between H and N ,the MAIN

side turn on.When unit detect voltage is 0VAC between H and N, the

MAIN side turn off.

C.2 When unit detect voltage is 230VAC between C and N, the ROOM

side turn on according to climate temp curve. When unit detect voltage

is 0V between C and N), the ROOM side turn off.

C.3 When H-N and C-N are detected as 0VAC, unit turn off.

C.4 when H-N and C-N are detected as 230VAC, both MAIN and

ROOM side turn on.

Procedure

1. Connect the cable to the appropriate terminals as shown on the

picture

2. Fix the cable with cable ties to the cable tie mountings to ensure

stress relief

NOTE:

1.The wiring of the thermostat should correspond to the settings

of the user interface. Refer to 10.7 Field setting/Room Thermostat.

2. Power supply of machine and room thermostat must be

connected to the same Neutral Line and (L2) Phase Line(for 3-

phase unit only).

There are three methods for connecting the thermostat cable (as

described in the picture above) and it depends on the application.

2. Room thermostat type 2(RT2)(Recommend wire connection

method): L N provide the power supply to the RT connector directly.

L connect from the unit main power supply port L of 1-phase power

supply , L2 of 3-phase power supply.

Wiring size

Voltage

220~240VAC

0.2A

0.75mm

2

Type 2

Control port signal type

Wiring size

Voltage 220~240VAC

0.2A

0.75mm

2

Type 2

Control port signal type

Loading...

Loading...