14

Table 4-5

Item Description Image Notice

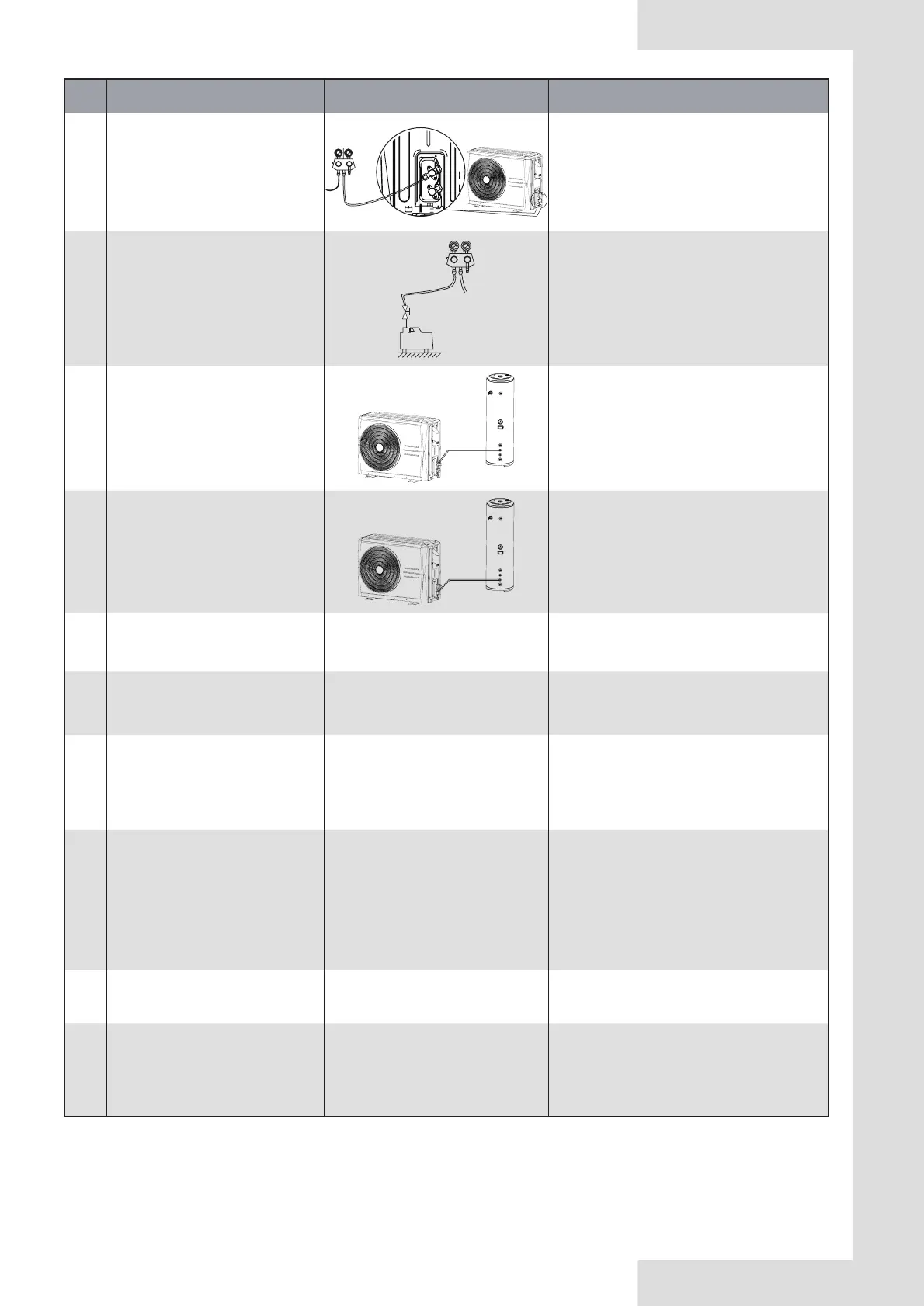

1

Connect the (low pressure side) hose

of a pressure gauge to the outdoor

unit gas pipe stop valve.

Before performing vacuum drying, make sure that

alltheoutdoorunitstopvalvesarermlyclosed.

2

Connect the hose to the vacuum

pump.

1.Mixingofpumplubricantwithcompressoroil

could cause compressor malfunction and a one-

way valve should therefore be used to prevent

vacuum pump lubricant seeping into the piping

system.

2. Using a vacuum pump with a discharge in

excessof4L/sandaprecisionlevelof0.02mmHg

is recommended.

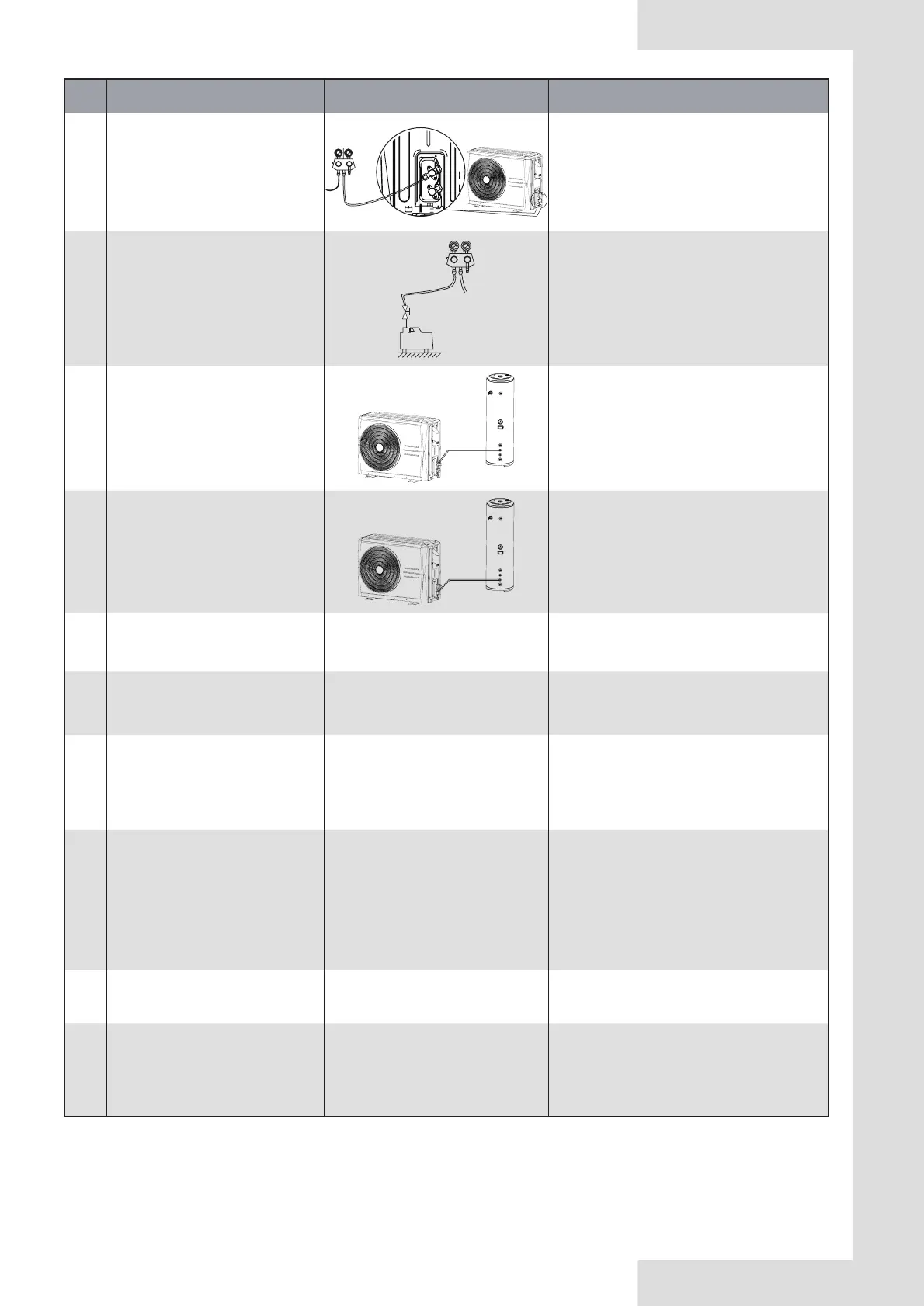

3

Connect the outdoor unit gas pipe

stop valve to water tank gas pipe

4

Connect the outdoor unit liquid pipe

stop valve to water tank liquid pipe

5

Start the vacuum pump and then

open the pressure gauge valves to

start vacuum the system.

6

After 15-20 minutes, close the

pressure gauge valves.

7

After a further 5 to 10 minutes check

the pressure gauge. If the gauge has

returned to zero, check for leakages

in the refrigerant piping. If the gauge

is no change, then vaccum drying is

OK.

8

Re-open the pressure gauge valves

and continue vacuum drying for at

least 20 minutes and until a pressure

dierenceof756mmHgormorehas

been achieved. Once the pressure

dierenceofatleast756mmHghas

been achieved, continue vacuum

drying for 20 minutes.

9

Close the pressure gauge valves and

then stop the vacuum pump.

10

After 1 hour, check the pressure

gauge. If the pressure in the piping

has not increased, the procedure

isnished.Ifthepressurehas

increased, check for leakages.

After vacuum drying, keep the hoses connected

to the pressure gauge and to the outdoor

unit stop valves, in preparation for refrigerant

charging.

4.5 Refrigerant charge

• Pipe length is 2~20m.

• If the pipe length is less than 10m, there is no need to add additional refrigerant charge.

• If the pipe length is more than 10m, adding additional refrigerant charge is necessary, and the rule is 20g/m for the additional pipe.

Loading...

Loading...