22

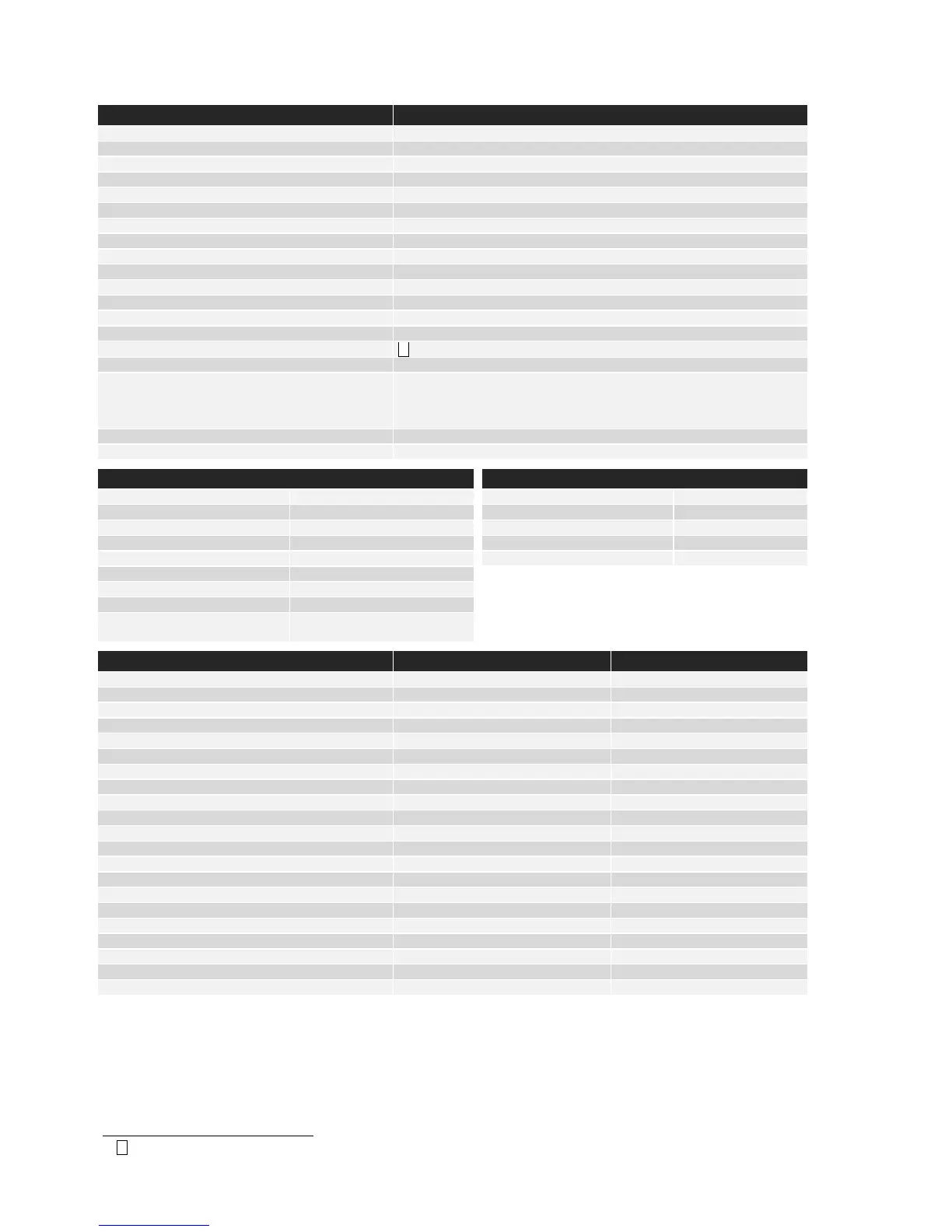

TECHNICAL DATA

POWER SOURCE FLEX

2

3000 C

Mains voltage ±15% (50-60Hz) 3x400 V

Fuse 16 A

Mains current, effective 16.5 A

Mains current, max.. 19.0 A (380V) / 18.1 A (400V)

Power, 100% 10.9 kVA

Power, max. 12.5 kVA

No load consumption 40 VA

Efficiency 0.85

Power factor 0.90

Current range 15-300 A

Duty cycle 20°C (MIG) 300A/100%

Duty cycle 40°C (MIG) 270A/100%

Duty cycle 40°C (MIG) 300A/80%

Open circuit voltage 69-76 V

Protection class IP 23

Standards

EN/IEC60974-1

EN/IEC60974-2

EN/IEC60974-5

EN/IEC60974-10 (Class A)

Dimensions (HxWxL) air cooled/water cooled 90.6x52.4x92.5 cm/105.1x52.4x92.5 cm

Weight air cooled/water cooled 58 kg/69 kg

WIRE FEED UNIT INTERNAL COOLING UNIT

Wire feed speed 0.5-30 m/min Cooling efficiency (1.0 l. flow) 1100W (1.0 l/min)

Torch connection EURO connection Tank capacity 3.5 litres

Wire-reel diameter 300 mm Flow 1.2 bar – 60°C 1.75 l/min

Duty cycle 40°C 420A/100% Pressure max.. 3 bar

Duty cycle 40°C 500A/60% Standards EN/IEC60974-2

Protection class IP 23

Wire diameter 0.6-2.4 mm

Gas pressure max. 0.5 MPa (5.0 bar)

Standards EN/IEC60974-5

EN/IEC60974-10 (Class A)

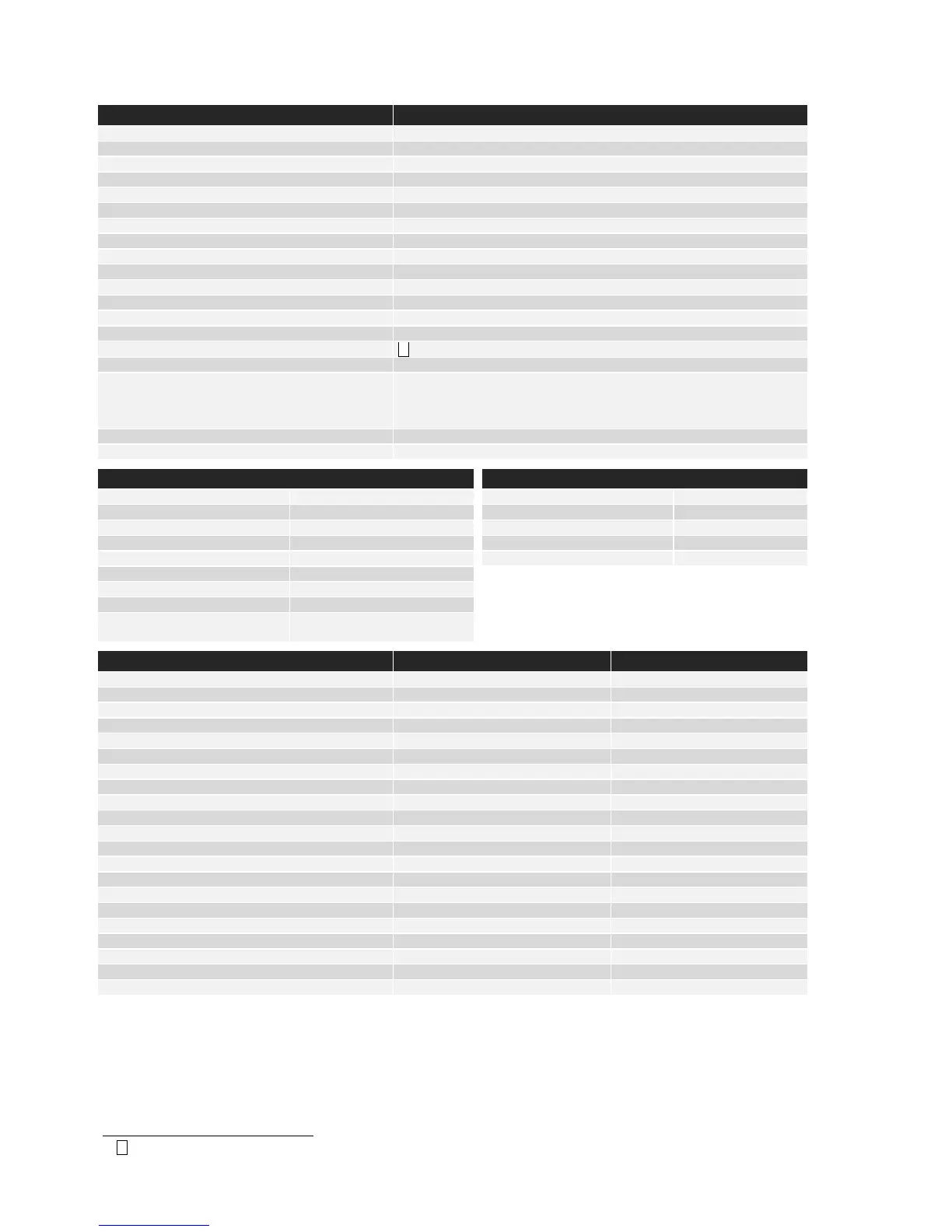

FUNCTION PROCESS VALUE RANGE

Selection of trigger mode MIG/MAG 2-times/4-times

Control of current/voltage/ wire feed speed - local/torch control/remote control

Wire inching MIG/MAG Yes

Torch cooling - water cooled/gas cooled

Hot-start % MMA 0.0% – 100.0%

Hot-start-time MMA 0.0 – 20.0 s

Arc power MMA 0.0 – 150.0%

Gas pre-flow MIG/MAG 0.0 – 10.0 s

Soft-start MIG/MAG 0.5 – 24.0 m/min

Hot-start Synergic -99% – +99%

Hot-start-time Synergic 0.0 – 20.0 s

Slope down Synergic 0.0 – 10.0 s

Stop Amp Synergic 0 – 100%

Stop Amp time Synergic 0.0-10.0 s

Burn back MIG/MAG 0 – 30

Gas post-flow MIG/MAG 0.0 – 20.0 s

Sequence timer / Spot welding time MIG/MAG 0.0 – 50.0 s

DUO Plus

efficiency MIG/MAG 0 – 50%

DUO Plus

time MIG/MAG 0.1 – 9.9 s

Electronic choke -5.0 – +5.0

Sequence 9 sequence steps

1

This machine meets the demand made for machines which are to operate in areas with increased hazard of electric chocks

2

Equipment marked IP23 is designed for indoor and outdoor applications

Loading...

Loading...