Maintenance

22

Cleaning & Sanitization

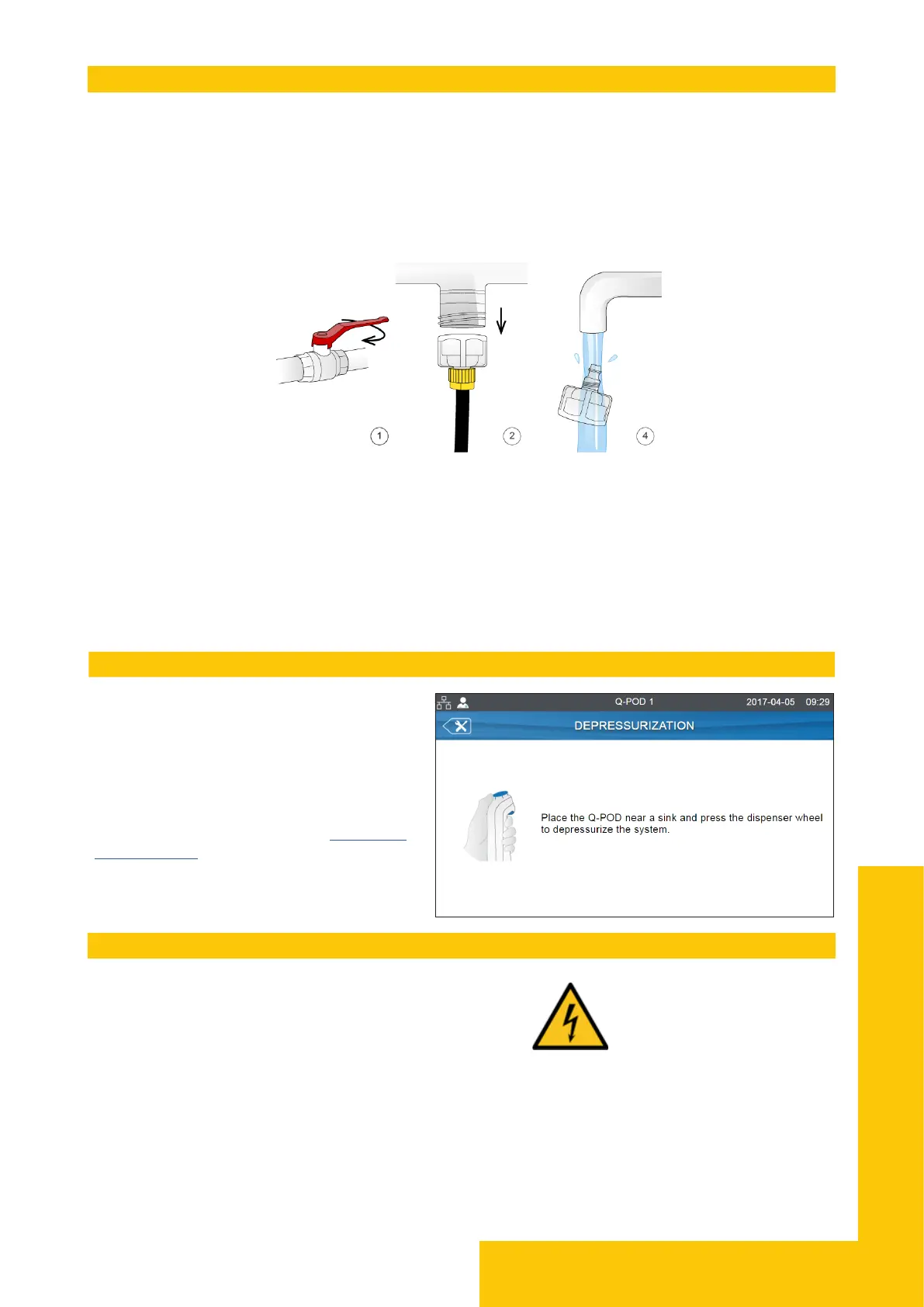

Cleaning the inlet strainer

This setting is only available when in a pressurized loop feed conguration.

The purpose of the inlet strainer is to prevent large particles from entering the Milli-Q system.

If the inlet strainer becomes clogged, then feed water does not ow freely to the system.

Select Care/Cleaning app and click on Inlet strainer clean. Follow the self-guided wizards.

Cleaning the A10 TOC Monitor

This is recommended when:

• A new set of IPAK cartridges are installed

• TOC values are uctuating

• TOC values are higher than normally seen

Select Care/Cleaning app and click on A10 monitor clean. For best results, an A10 clean

should be performed for its full duration (60 minutes). If necessary, repeat the procedure.

Depressurization

This temporarily stops production and all

water processes.

This function is not necessary during

normal system operation. See self help

guide section.

ech

2

o UV lamps - mercury free

Contact the technical support hotline to organize a

replacement visit.

It is highly recommended to have a qualied Milli-Q

eld service representative to change the 172 nm UV

lamps. Replacement of the lamps involves removing

the panels of the Milli-Q system.

Hazardous voltage!

Hazard of electrical arc ash will

cause death or serious injury.

Important! Never open the system, even when the power switch has been switched off.

It is not sufcient to switch off the system, the plug must be physically removed from its power

source. Installation and maintenance should only be done by a qualied person. Appropriate

personal protective equipment (PPE) must be worn and safe work practices must be followed.

Loading...

Loading...