CHAPTER 7 – 7200 CNC OPERATION

7 The Function Keys

Highlighted Function Keys are active or available.

8 Status Window

Status Window displays detailed information on the state of the control. A

detailed description is given below.

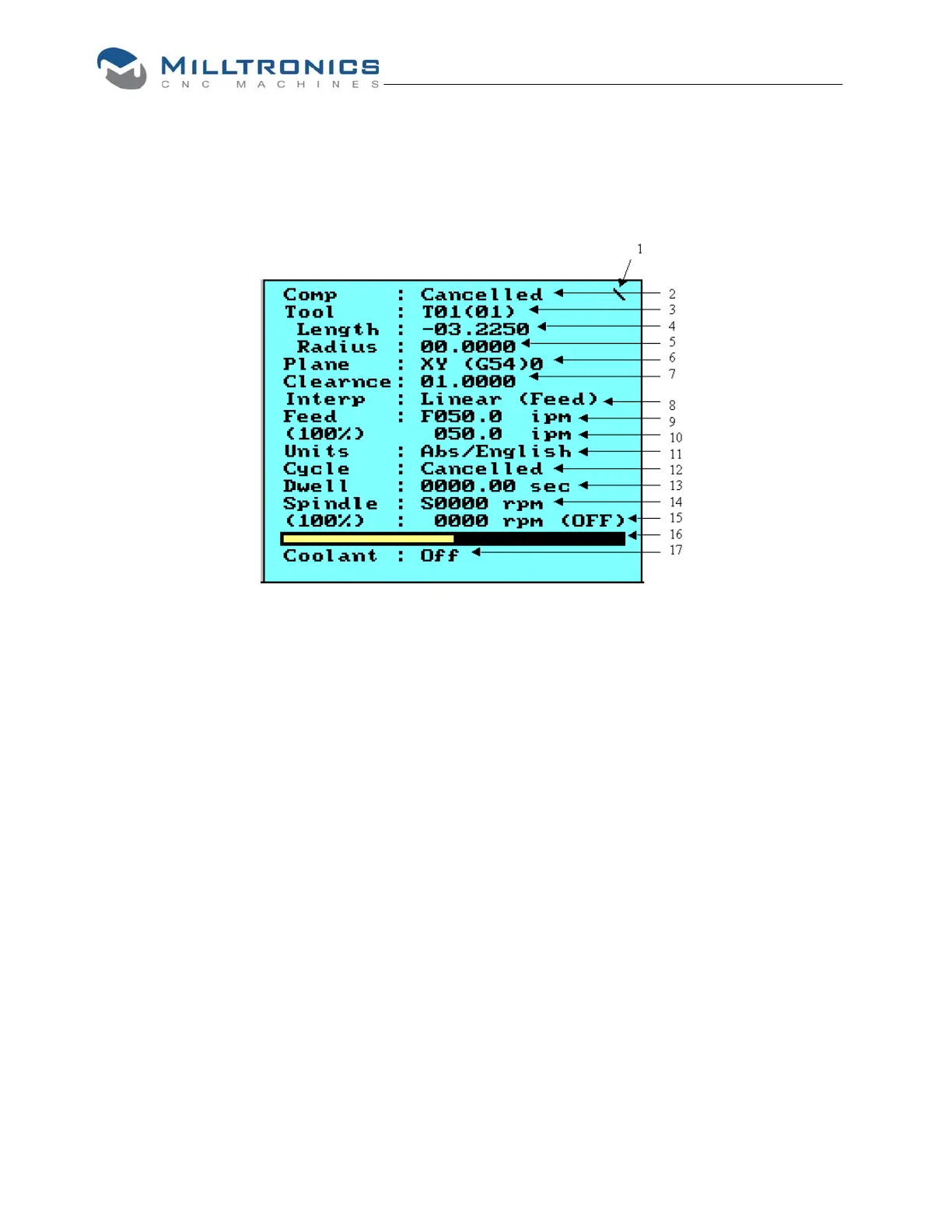

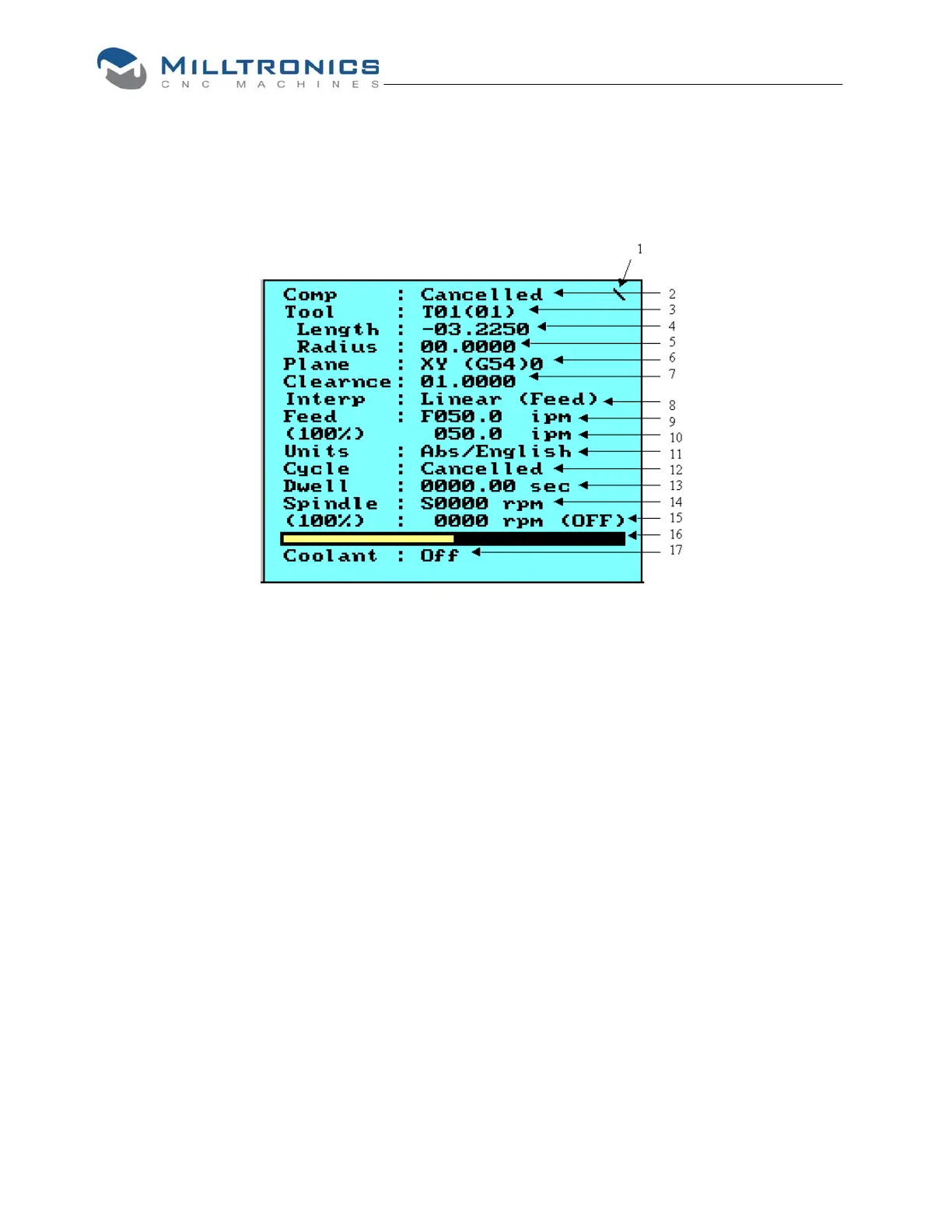

Diagram of Status Window

1 The \ changes back and forth to / and \ each time the status window is updated.

2 Comp: Tool Radius Compensation (Left, Right or Cancelled)

3 Tool: The first two digits indicate the active tool number. The second two digits in

parentheses indicate the pending tool number. If you execute a T14 without the

M6 the pending tool number will be 14.

4 The tool length.

5 The tool radius.

6 Plane and work offset: The plane is XY (G17), ZX (G18), or YZ (G19). The work

offset shows the current work offset G54 (0)…G59 (9).

7 Clearance or R-Plane.

8 Interpolation, Linear (Feed), Linear (Rapid), Circular (CW), or Circular (CCW)

9 Feedrate: The programmed feedrate and its units (English feed per minute) ipm,

(Metric feed per minute) mmpm, (English feed per revolution) ipr, (Metric feed per

revolution) mmpr or (inverse feed) /min or /sec (If the machine is rapid mode the

units will always be ipm or mmpm.)

10 Feedrate override: The position of the feedrate override and the resulting

feedrate. If the machine is programmed to move faster than its maximum, the

clamped feedrate will be displayed, and an “*” will be displayed next to the %.

11 Units: (Absolute) Abs or (Incremental) Inc and English or Metric

12 Cycle: If there is a canned cycle or autoroutine active it will be displayed on this

line.

13 Dwell: When a dwell is executed the dwell time will count down to zero.

14 Spindle: The programmed revolutions per minute.

55

Loading...

Loading...