- 5 -

MINGDA TECHNOLOGY CO.,LTD

www.md-3d.com

4 Manual Calibration

Note: before calibration, you need to dismantle the model and put on

new tapes.

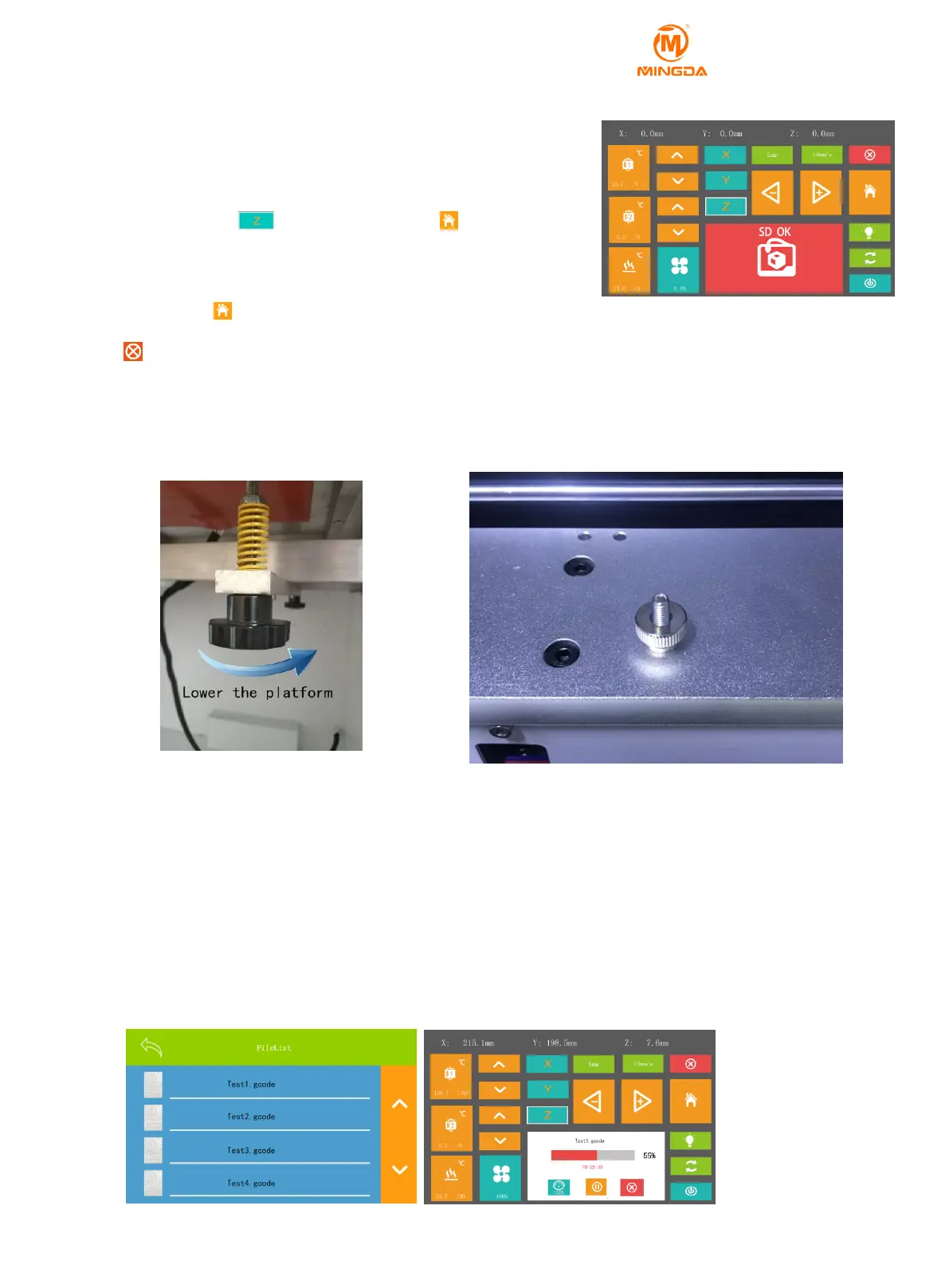

Enter the adjust platform interface

1. Choose "Z" axis , and click reset button to raise the hot bed

to the highest degree.

Fine Tune the Printing Platform

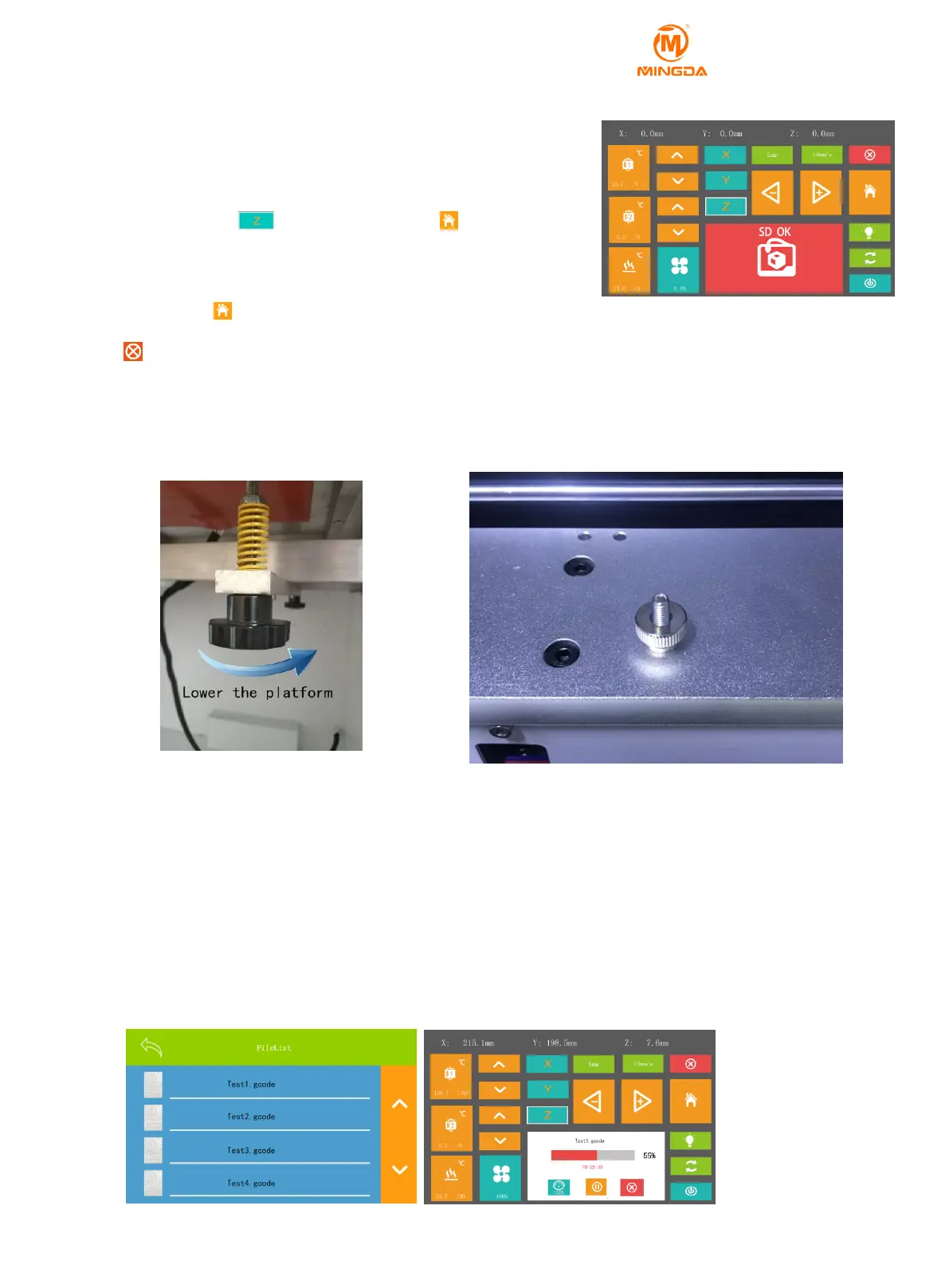

Adjusting the overall height of the Printing Platform

If you want to add a glass or other material plate on a hot bed, you need to move the limit block position up,

and adjust the platform level again.

Printing the Test Files

Click on the SD card icon, choose a gcode file which you want and print.

Tip: You can fine-tune the platform during the first layer of printing. When printing the first layer, if the

filament is not stuck on the hot bed, you need to adjust the nuts counterclockwise; if the tape is scraped, adjust

nuts clockwise.

The best printing condition is, the filaments stick on the hot bed and form a flat strip instead of strips or flats.

1. Click Reset to raise the platform

position to the highest position. Click

to unlock the motor. then you can

gently push the print head to the four

corners and the middle position of

the platform, observe the gap

between the nozzle and the hot bed

at any time.

2. The gap requirement is about 0.1mm. You can insert an A4 paper

between the nozzle and the printing platform, and push the

printing head to the four corners and the center of the platform,

at the same time adjust the four fine-tuning nuts to ensure that

the paper can be moved with resistance but not scratched.

Loading...

Loading...