3. DISPLAY AND OPERATION SECTIONS

3 - 7

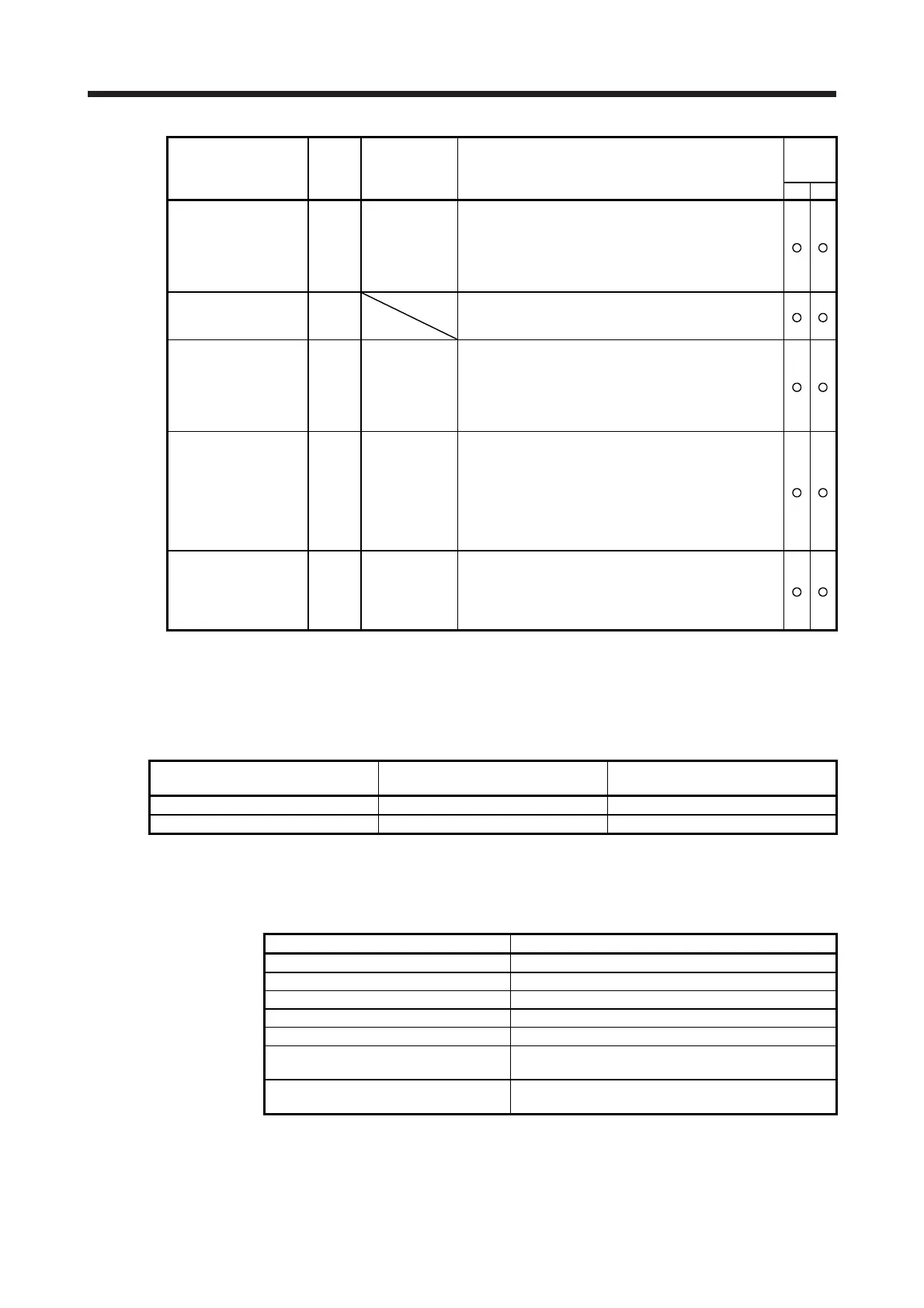

Status display Symbol Unit Description

Control

mode

(Note 1)

CP CL

Cam axis feed current

value

CCMd

10

STM

μm

10

(STM-4)

inch

10

-3

degree

pulse

(Note 2)

A feed current value during the cam axis control is displayed.

The values in excess of ±99999 can be counted. However, the

counter shows only the lower five digits of the actual value since

the servo amplifier display is five digits.

When the simple cam function is disabled, 0 is always displayed.

Refer to section 6.1.8 for detecting point.

Cam No. in execution Cno

Cam No. in execution is displayed.

When the simple cam function is disabled, 0 is always displayed.

Refer to section 6.1.8 for detecting point.

Cam stroke amount in

execution

CSTK

10

STM

μm

10

(STM-4)

inch

10

-3

degree

pulse

(Note 2)

Cam stroke amount in execution is displayed.

The values in excess of ±99999 can be counted. However, the

counter shows only the lower five digits of the actual value since

the servo amplifier display is five digits.

When the simple cam function is disabled, 0 is always displayed.

Refer to section 6.1.8 for detecting point.

Main axis current value MCMd

10

STM

μm

10

(STM-4)

inch

10

-3

degree

pulse

(Note 3)

A current value of the input axis (synchronous encoder axis or

servo input axis) is displayed. Unit is increment of input axis

position.

The values in excess of ±99999 can be counted. However, the

counter shows only the lower five digits of the actual value since

the servo amplifier display is five digits.

When the simple cam function is disabled, 0 is always displayed.

Refer to section 6.1.8 for detecting point.

Main axis one cycle

current value

MCyC

10

STM

μm

10

(STM-4)

inch

10

-3

degree

pulse

(Note 3)

The input travel distance of the input axis in a range between 0

and (cam axis one cycle length setting - 1) is displayed. Unit is

an increment of cam axis one cycle.

When the simple cam function is disabled, 0 is always displayed.

Refer to section 6.1.8 for detecting point.

Note 1. CP: Positioning mode (point table method)

CL: Positioning mode (program method)

2. The unit can be selected from μm/inch/degree/pulse with [Pr. PT01].

3. Depending on the setting of [Cam control data No. 30 Main shaft input axis selection], the parameters used to

set the unit and feed length multiplication will change as follows. For details of each parameter, refer to section

6.1.7 (3) and 7.2.7.

Setting of [Cam control data No. 30] Parameter for the unit setting

Parameter for the feed length

multiplication setting

"0" or "1" [Pr. PT01] [Pr. PT03]

"2" [Cam control data No. 14] [Cam control data No. 14]

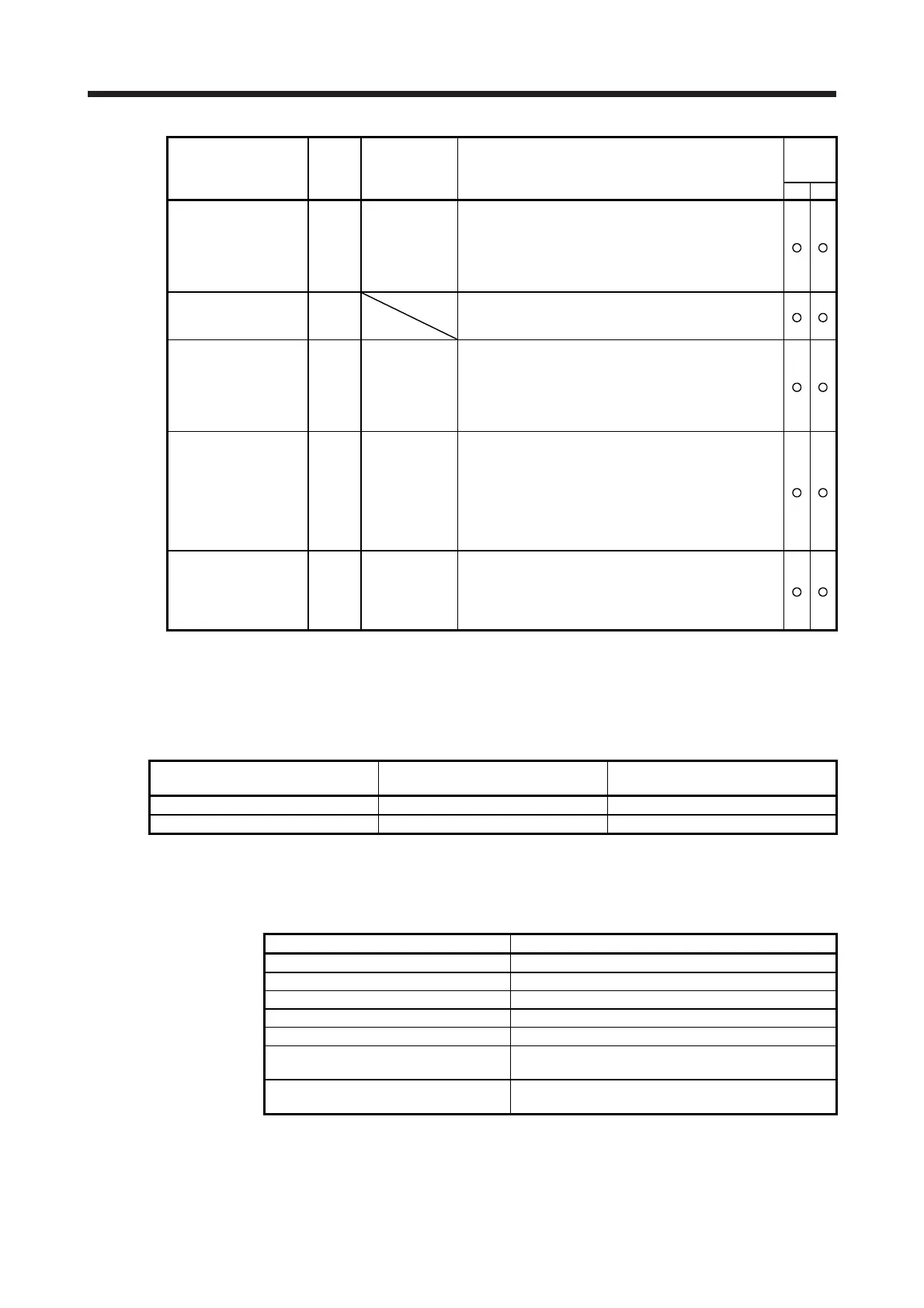

(3) Changing the status display screen

The status display on the servo amplifier at power-on can be changed with [Pr. PC36]. The status

displayed by default varies depending on the control mode as follows:

Control mode Status display

Position Cumulative feedback pulses

Position/speed Cumulative feedback pulses/servo motor speed

Speed Servo motor speed

Speed/torque Servo motor speed/analog torque command voltage

Torque Analog torque command voltage

Torque/position

Analog torque command voltage/cumulative feedback

pulses

Positioning (point table method/program

method)

Current position

Loading...

Loading...