7-32

Chapter 7 ASSEMBLY OF BASIC ENGINE

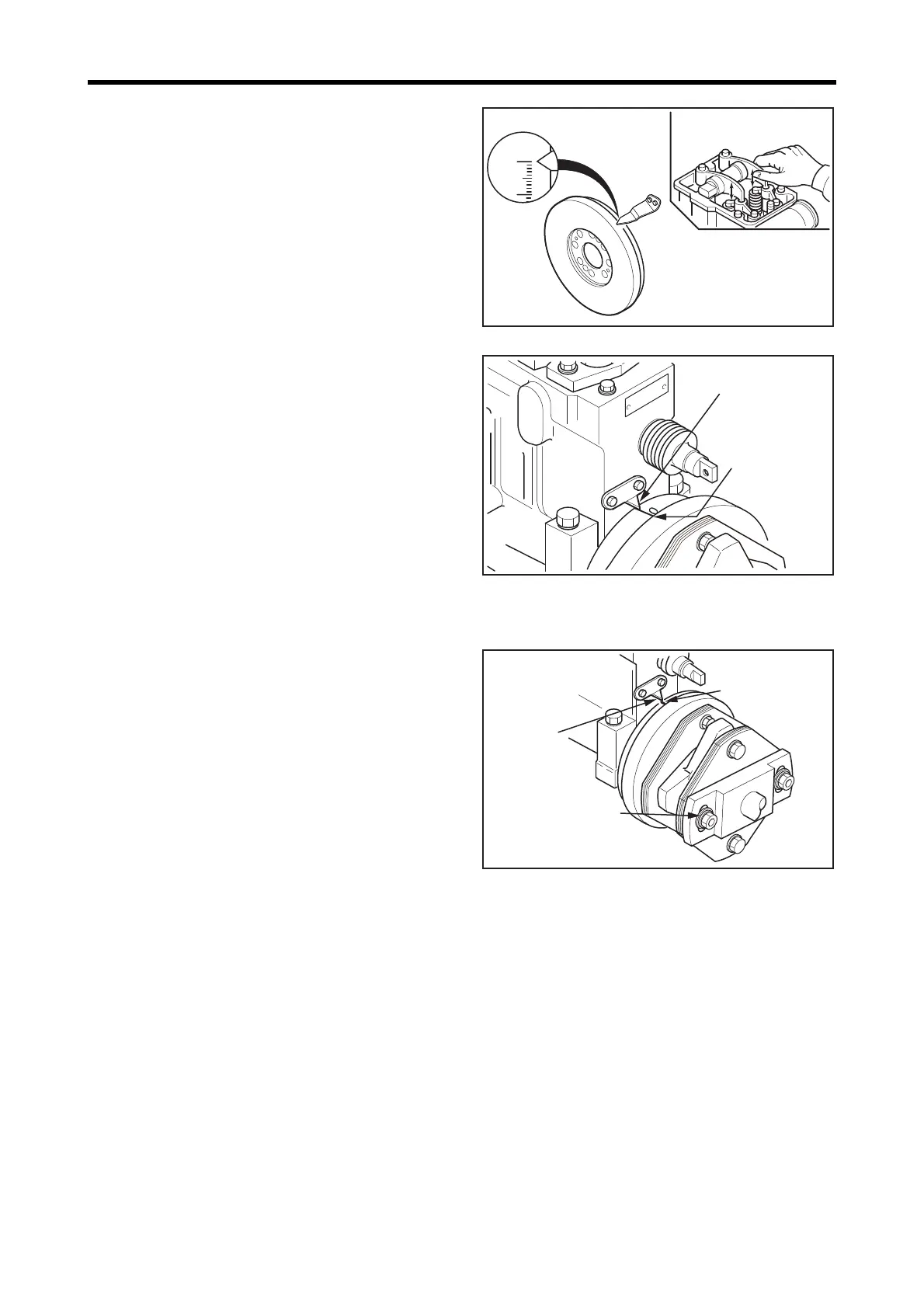

5.14.2 Fuel Injection Timing - Check

(1) Turn the crankshaft in normal direction, and stop the

turning when the No. 1 cylinder is positioned at approx

10° before the specified fuel injection timing.

Check that the "0" stamped line of fuel injection pump

flywheel indicates before the pointer.

Note: In this condition, the clearances of inlet and exhaust

valves are as specified, and valves are not pushed

down.

In case of the exhaust stroke top dead center, valves are

pushed down.

(2) Turn the crankshaft to the normal direction progres-

sively, align the fuel injection timing mark on damper

with engine pointer.

If the "0" line mark of fuel injection pump flywheel

aligns with pointer, the fuel injection timing is adjusted

to the specified timing.

If the "0" line mark does not align with pointer, adjust

the fuel injection timing.

TDC for Cylinder No.1 - Positioning

Fuel Injection Timing - Check

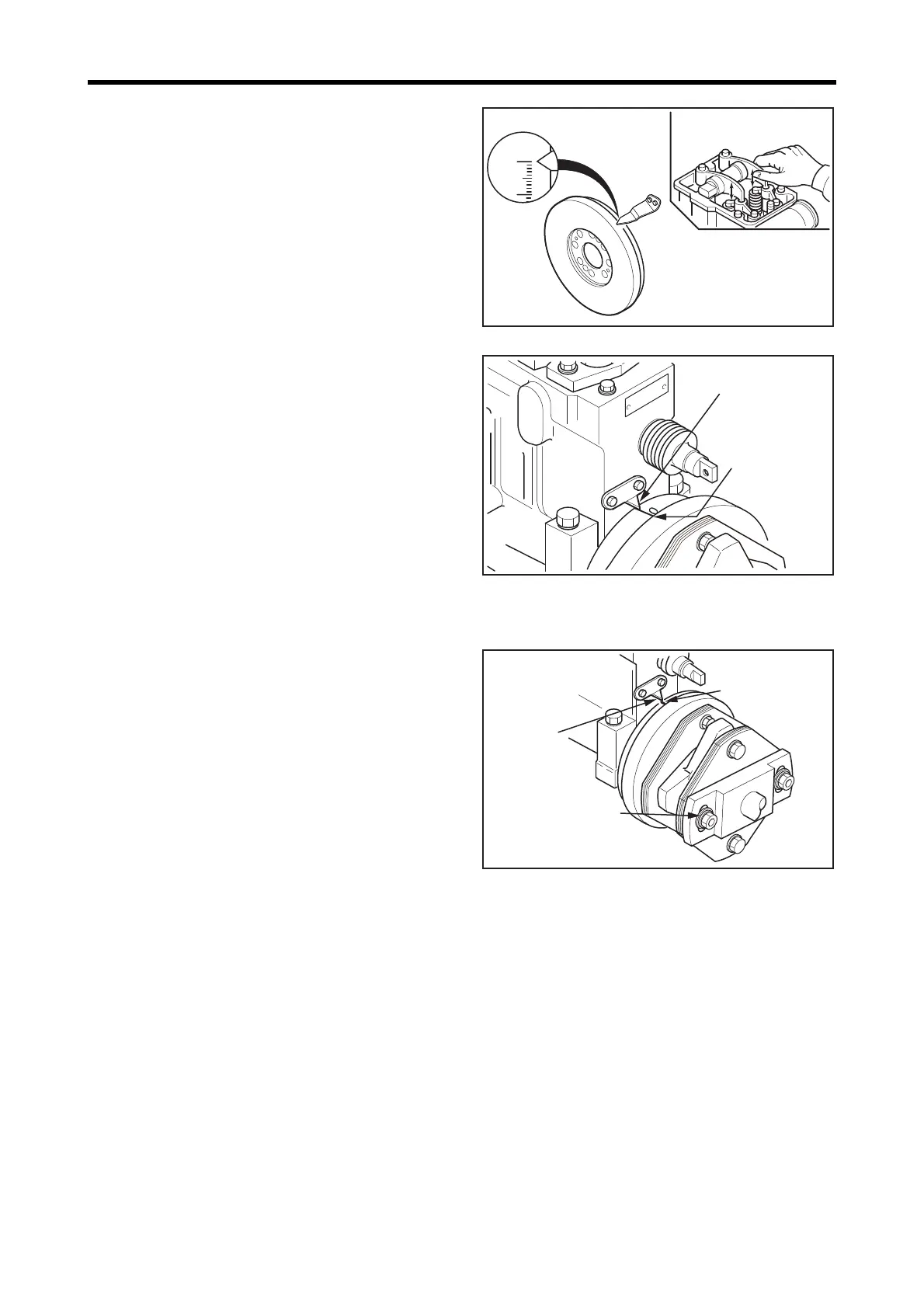

5.14.3 Fuel Injection Timing - Adjust

(1) Turn the crankshaft to the normal direction progres-

sively, align the fuel injection timing mark on damper

with engine pointer.

(2) Loosen the bolts (long) of driving coupling, and rotate

the fuel injection pump only. Adjust the "0" line mark

to pointer, then tighten the bolts (long.)

(3) From the specified fuel injection timing, turn the crank-

shaft in the reverse direction by approx 10°.

(4) Turning the crankshaft to the normal direction progres-

sively again, align the line mark of fuel injection timing

with the pointer.

In this condition, check the "0" line mark of fuel injec-

tion pump flywheel aligns with the pointer.

Repeat the step (2) until the proper alignment is made.

Fuel Injection Timing - Adjust

Check forcompression

top dead center

Pointer

Line mark on

the flywheel

Pointer

Line mark on

flywheel

Bolt (long)

M14:118 ± 5 N·m

{12 ± 0.5 kgf·m}

[87 ± 3.7 lbf·ft]

2-time tightening method

M12:108 ± 5 N·m

{11 ± 0.5 kgf·m}

[80 ± 3.7 lbf·ft]

2-time tightening method

Loading...

Loading...