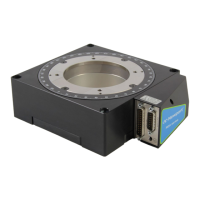

RGA Series Low profile fast rotation stage

A1355A0 – EDH0427En1010 – 04/21 2

2.0 Description

The RGA is the latest world class rotation stage from MKS that adds to the

breadth of readily-available, standard, precision stages. The RGA was

designed to move fast, with a low-profile and a large aperture. It addresses

the need for quick angle adjustments of wafers and vacuum chucks.

Although specifically tailored to semiconductor applications, the RGA can

also be utilized in other industrial applications, such as through hole

imaging/inspection or laser processing, automation or any general

positioning application that requires fast positioning response.

With a sub-mdeg MIM, the RGA is at the same level of positioning

precision as the industry-proven RGV stages. Compared to the RGV, the

lower profile RGA is able to handle faster speeds, similar MIM and loads up

to the typical weight of the chuck and wafer in semiconductor wafer

applications.

The excellent repeatability and mapped sub-mdeg accuracy of the RGA are

a result of MKS’ experience in design and precision manufacturing.

Tolerances down to micron level, enable almost perfect fits on the various

machined or ground components of the bearings and mounting surfaces of

the motor and encoder.

Design:

With a high peak torque output direct drive motor, the RGA can achieve

high accelerations needed to minimize move times. The single row bearing

design is manufactured to exacting tolerances, ensuring low wobble and

eccentricity, resulting lower, geometry-induced errors. This single row

bearing design is an improved version of those found in other MKS rotation

stages. The high resolution, non-contact encoder, enables the precise MIM

and repeatability needed for semiconductor wafer applications, coupled with

the high reliability required in industrial settings.

Mounting pads are included in the RGA in case the mounting surfaces are

not as flat as required. These pads distribute the weight and overcome the

flatness found in most commercially available isolation tables, leading to a

performance close to what is achieved under ideal conditions.

Unique features:

A number of features sets the RGA apart from other direct drive rotation

stages, including other MKS products. (low profile, fast rotation, large

aperture for chuck utilities, less Abbe error, wider bearing, less geometric

errors, so better wobble and eccentricity).

The RGA’s large aperture allows more utilities through the stage and

connected to the wafer chuck. More vacuum zones can be designed,

ensuring a flatter wafer. With more room the strain or drag from hoses

and/or cables are minimized, which increases reliability and reduces the

torque/power required to accelerate. For through hole applications, this

simply means larger samples can be inspected or processed.

The RGA’s low profile enables the lowest possible position of the wafer

relative to the XY which reduces the effect of geometrical errors from the

XY and also from the RGA. This eventually improves accuracy and

repeatability at the wafer level, providing better confidence in the

measurements or the process. With more accurate placement of the wafer,

this reduces the need to correct for these geometric errors, implying a

reduction is process times.

The high torque, direct drive motor enables high accelerations for fast

positioning or alignment of the wafer. High torque can overcome the

friction introduced by the hoses and cable. A non-contact motor means no

wear of the motor components, ensuring reliable operations for years. Fine

Loading...

Loading...