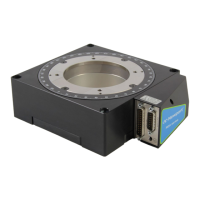

RGA Series Low profile fast rotation stage

3 A1355A0 – EDH0427En1010 – 04/21

magnet pitch enables higher MIM capability for those precise positioning

application needs.

Fast rotation and high acceleration enables faster completion of the process,

whether this is patterning, testing, inspection or repair of the wafer. The

response and settling times are also optimized with the structural design of

the RGA. All these enable faster throughputs.

The RGA uses non-contact motor and encoders, which not only provides the

speed, MIM and repeatability, but also improves reliability, since there is no

wear in these components. This minimizes the long term operating costs.

ESP technology, plug and play for quick and safety setups contributes to the

lower Cost of Ownership. Since stage parameters are already configured in

the XPS controller, there is very little amount or need to adjust the operating

parameters to begin using the stage quickly and more importantly, safely.

Like all MKS motorized products, each RGA is shipped with a free test

report that documents the positioning performance of each individual unit

meeting the published specifications. For higher accuracy, a mapped version

RGA150MAP is available.

Value:

In summary, the design, features and resulting performance of the RGA

ensures fast and reproducible processes. Reliability also increases due to the

non-contact components. All these reduces risk in a production setting and

also overall operating cost.

2.1 Design Details

Large diameter steel ball bearings

High torque & speed brushless DC motor with rare earth magnet

None: continuous movement

Optical index pulse, fixed at position 0°

Loading...

Loading...