9

8-504.11

INSTALLATION

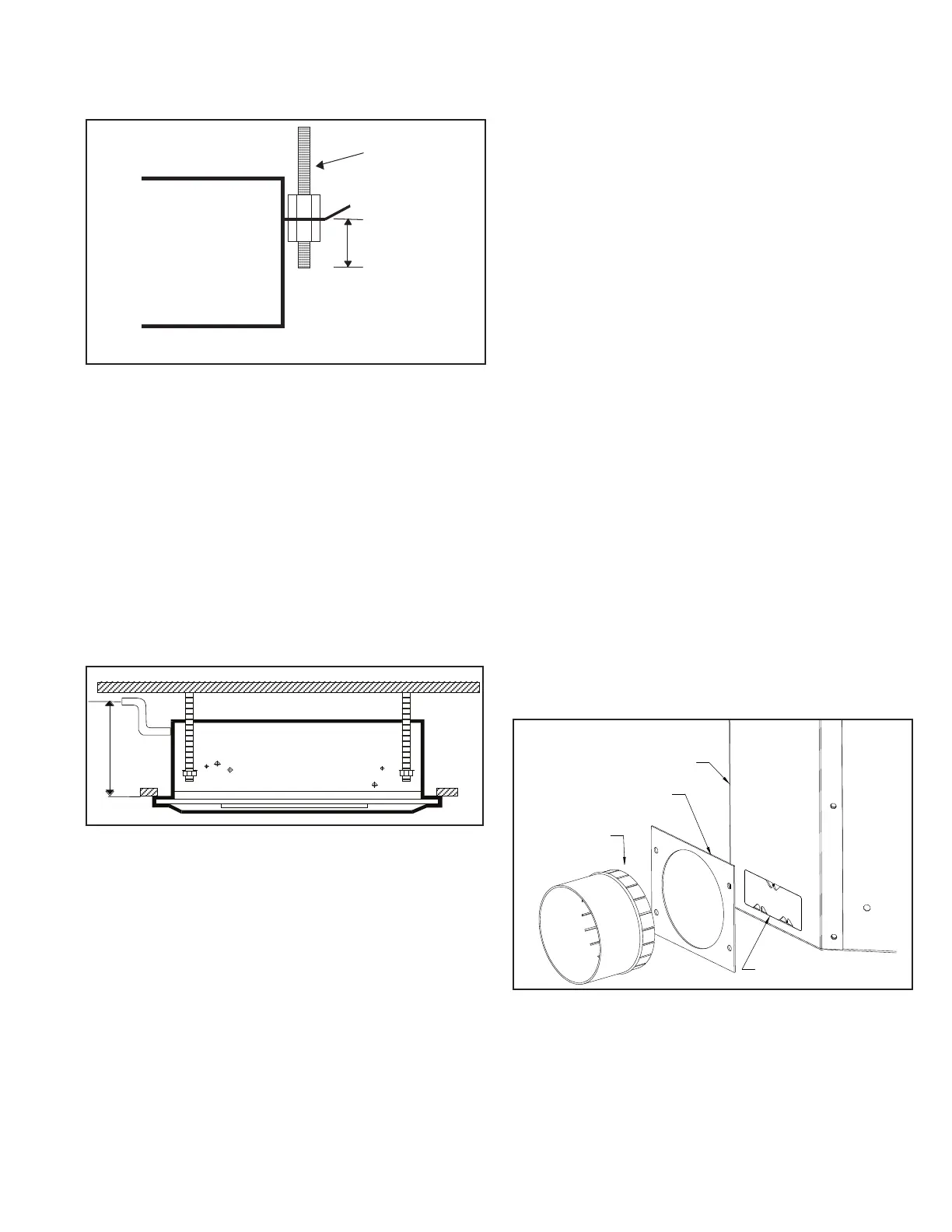

Figure 9.1 - Threaded Rod Dimension

Threaded Rod

< 2 in (5 cm)

3/8 in

Condensate Piping

The unit is supplied with a 3/8" ID exible hose for connection to

copper or plastic drain piping.

When installing the unit consider the following:

1. Maximum pump lift is 30 in (76.2 cm).

2. The highest point in the condensate piping should be as

close to the unit as possible.

3. Condensate piping should slope downwards in the direction

of water ow with a minimum gradient of 1 in per 100 in

(2.54 cm per 254 cm). There must not be any upward

gradients other than in the rst 30 in (76.2 cm) of piping

from the unit. Once the piping begins the downward

gradient, the piping must continue to be in a downward

gradient. See Figure 9.2.

Figure 9.2 - Condensate Piping

30 in

(76.2 cm)

Max

4. When multiple units are connected to a common

condensate drain, ensure the drain is large enough to

contain the volume of condensate from all units. It is

recommended to have an air vent in the condensate piping

to prevent any air locks.

5. Condensate piping must not be installed where it may be

exposed to freezing temperatures.

Duct Collars

Supply air branch duct and outside air duct collars can be

attached to the unit chassis by following the below steps:

Supply Air Duct Collars:

1. Up to two supply air ducts can be attached per unit.

2. Place the polystyrene blanking strip in the fascia supply air

opening on the same side where the supply duct collar is to

be installed.

Outside Air Duct Collars:

1. Two outside air openings are available on small casing

sizes (size 08 & 12). Three outside air openings are

available on medium and large casing sizes (size 18 and

higher).

2. Replace the washable lter with the pleated lter provided

with the fresh air duct collar kit.

3. To maximize the amount of outside air through the

knockouts, use all available fresh air openings, the pleated

lter, and high fan speed.

Installing Outside and/or Supply Air Duct Collars:

1. Refer to the dimensional drawing on page 20 page 24

to for knock-out hole locations.

2. The insulation is pre-cut to aid location and removal of the

relevant section. Rub hand across surface of insulation to

reveal exact location of knock-out.

3. Remove the metal knockout from the chassis.

4. Place the duct collar’s tabs inside the duct collar ange’s

opening. Bend the tabs around the duct collar ange’s

opening.

5. Using eld provided self-tapping screws, attach the duct

ange and collar to the chassis with the bent tabs being

sealed in between the unit chassis and duct collar ange.

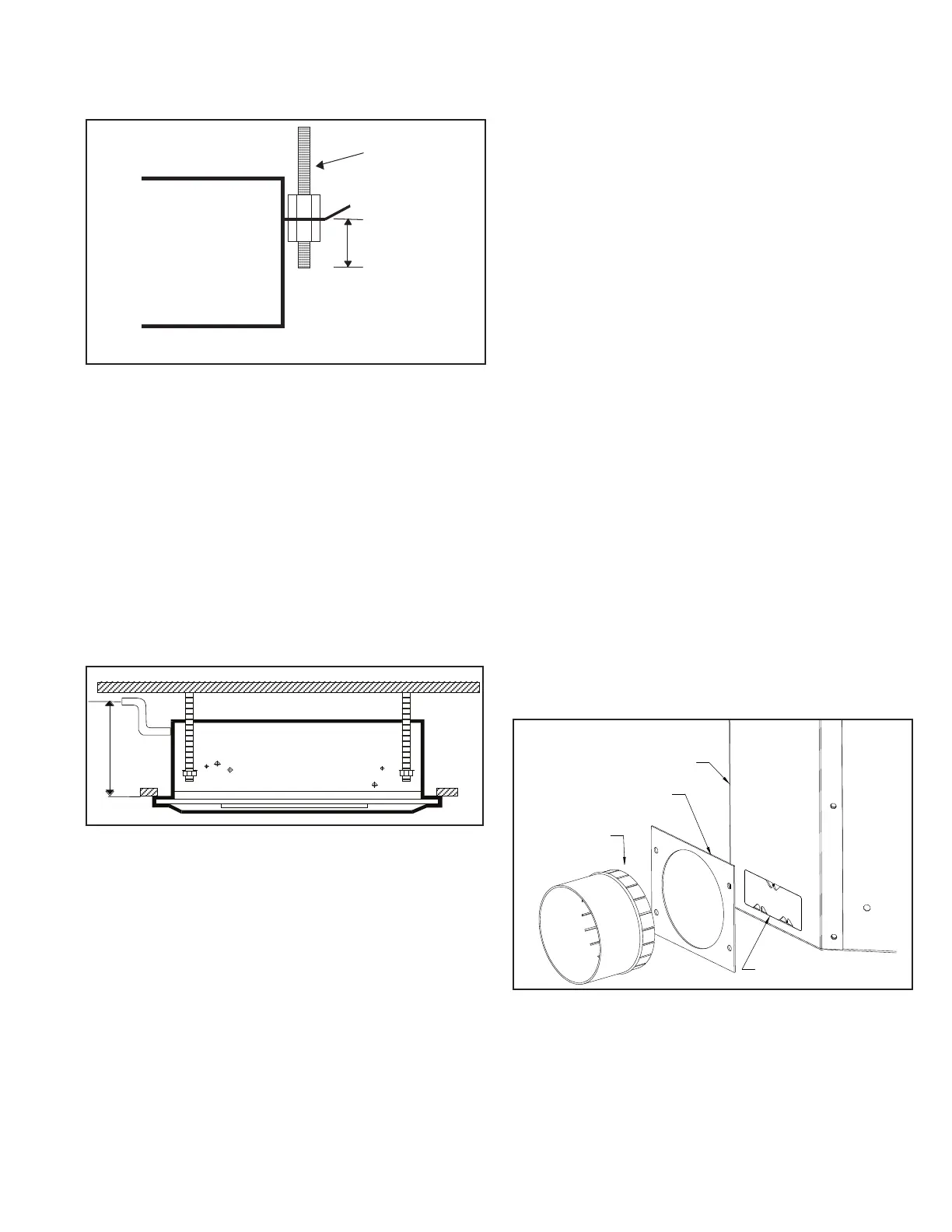

See Figure 9.3 for duct collar assembly.

Figure 9.3 - Duct Collar Assembly

DUCT COLLAR

DUCT COLLAR FLANGE

UNIT CHASSIS

OUTSIDE AIR KNOCKOUT

Note: See Figure 20.1, Figure 21.1, Figure 22.1, Figure 23.1

and Figure 24.1 for Branch Duct and Fresh Air Duct

locations and dimensions.

Loading...

Loading...