5 Metering principle

The dosing auger of the MC18-Micro combined with a very precise

adjustable stepping motor ensures that the additive output is

accurate and regular. For every particular application Movacolor

provides different neckpieces but the most common mounting of

the neckpiece is between the production machine and the hopper.

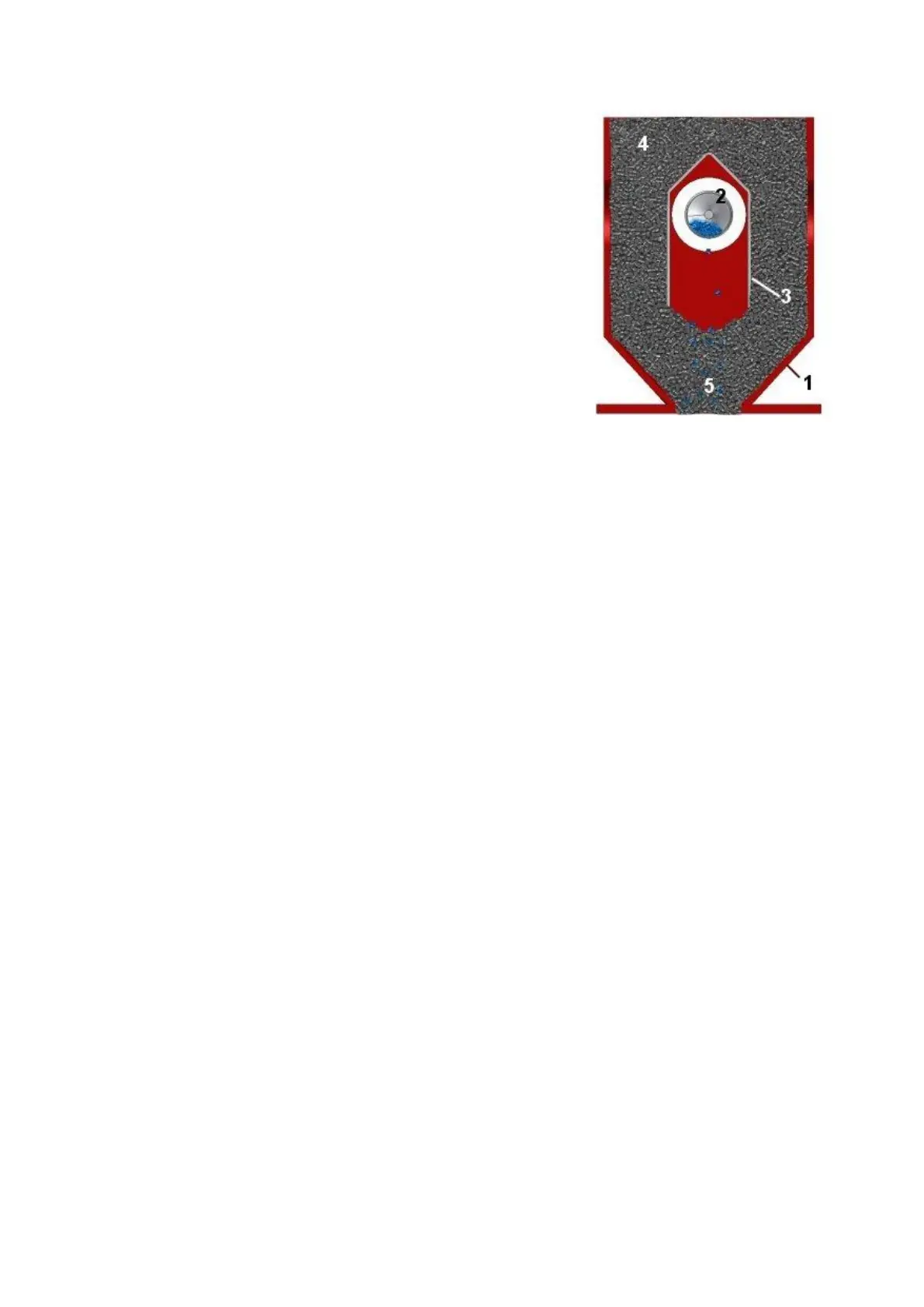

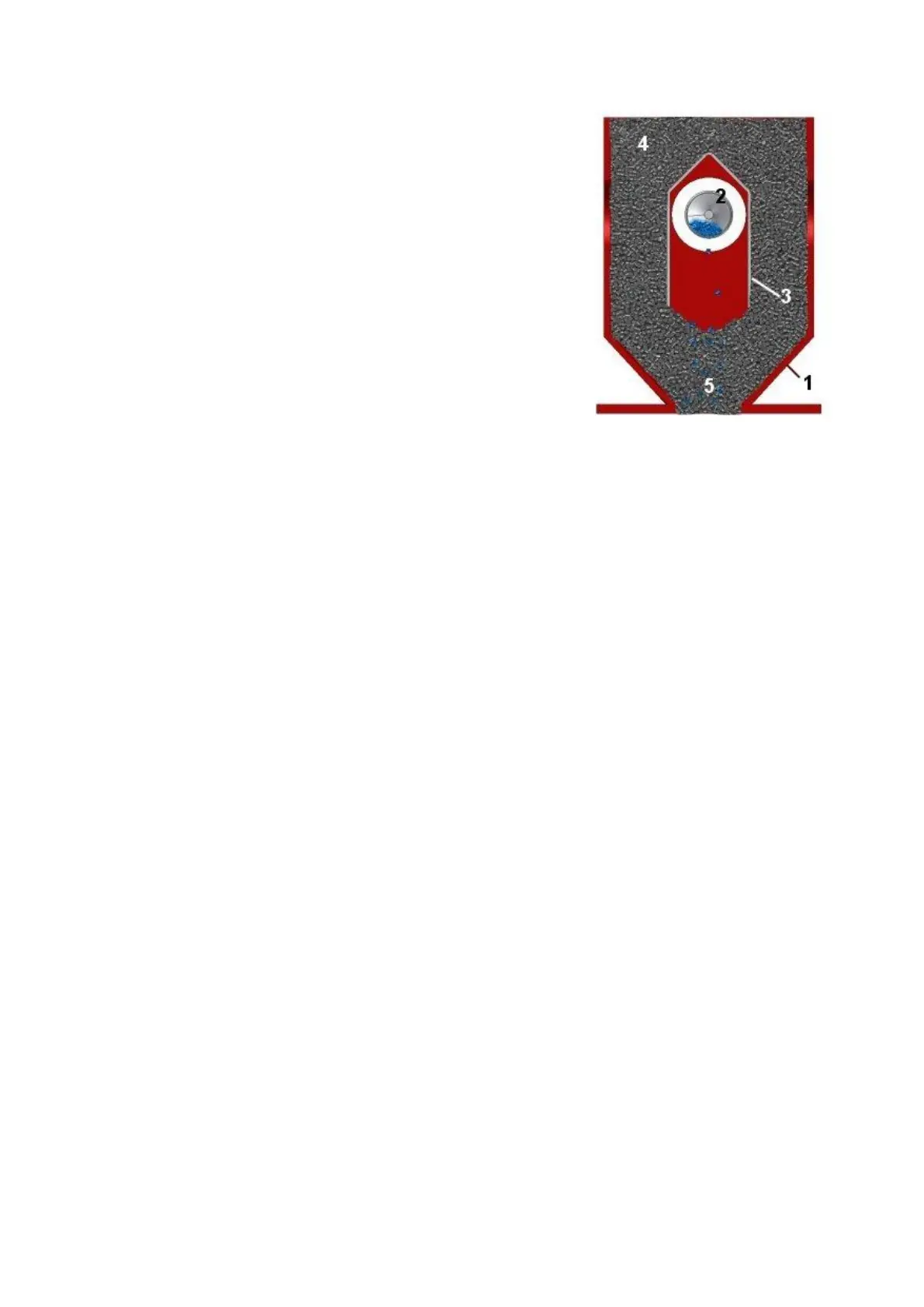

In the figure below a cut through of the NST40 neckpiece can be

seen.

During operation, the virgin material runs from the

machine hopper through the neckpiece (1) into the

machine. Inside the neckpiece the virgin material flow (4)

is divided into two streams by the cover plate(3). In the

space below the cover plate, the rotating cylinder (2) is

dosing additive.

Additive is added directly into the center of the virgin

material flow, just before it enters the production

machine (5). This is a great advantage over metering devices

that use batch pre-mixing because pre-mixing can

actually cause material separation. Separation of

materials results in an irregular additive flow into the

production machine.

Loading...

Loading...