67

Cylinders

G1 SCBA 2018 Edition

US

When replacing a cylinder valve assembly or after retesting the cylinders, make sure the correct

cylinder valve, burst disc, and O-ring are installed before charging the cylinder.

Determine the maximum service pressure of the cylinder. Fill all cylinders only to the designated

service pressure found on the DOT approval or stamping. For cylinders manufactured under a US

DOT exemption (i.e., DOT-E- #####), consult the exemption, which is available from the Research

and Special Programs Administration (RSPA), US Department of Transportation, 400 7th Street, SW,

Washington, DC 20590-0001.

12.2 Preparing Cylinders for Use

For remote connections, make sure the dovetail bracket is attached to the cylinder before use. If the

dovetail is not available, do the following:

(1) Remove the old cylinder boot and insert (if equipped)

from the cylinder.

(2) If MSA cylinders are already available, use the

following table to determine which cylinder retainer kit

is necessary.

P/N Cylinder

NIOSH Service

Life Rating

Pressure

Retainer

Type

Retainer Kit

P/N

807586 L-30 Carbon 30 minutes 2216 psig Type 4 10158401

807587 H-30 Carbon 30 minutes 4500 psig Type 2 10158389

807570 H-45 Carbon 45 minutes 4500 psig Type 4 10158401

10035644 H-45 LP Carbon 45 minutes 4500 psig Type 3 10158390

807588 H-60 Carbon 60 minutes 4500 psig Type 5 10158402

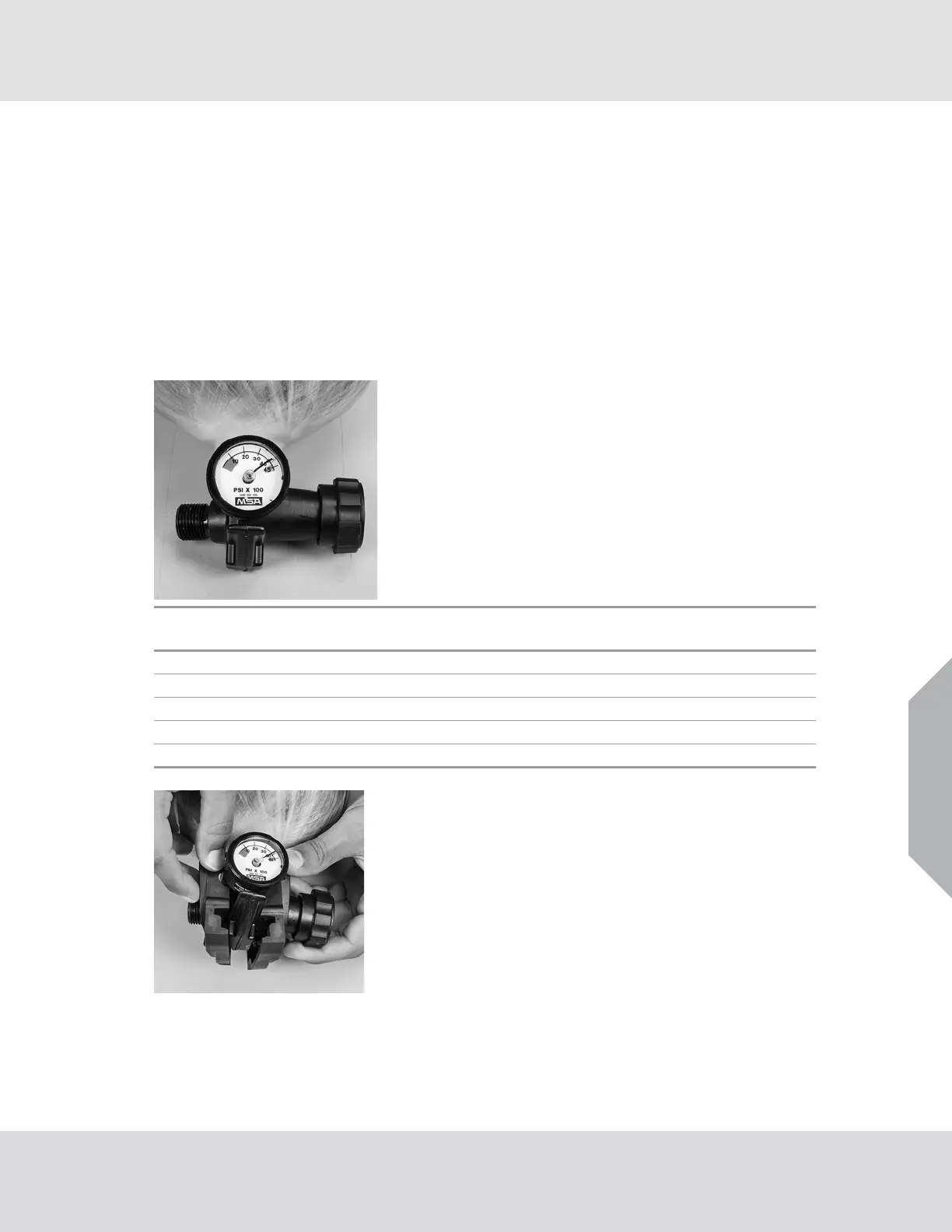

(3) Attach the retainer halves to the cylinder valve assembly.

Loading...

Loading...