PAGE 38 — LD6 RIDE-ON POWER TROWEL • OPERATION MANUAL — REV. #0 (02/10/20)

4. Repeat steps 1–3 for the remaining grease fittings on

both spider assemblies.

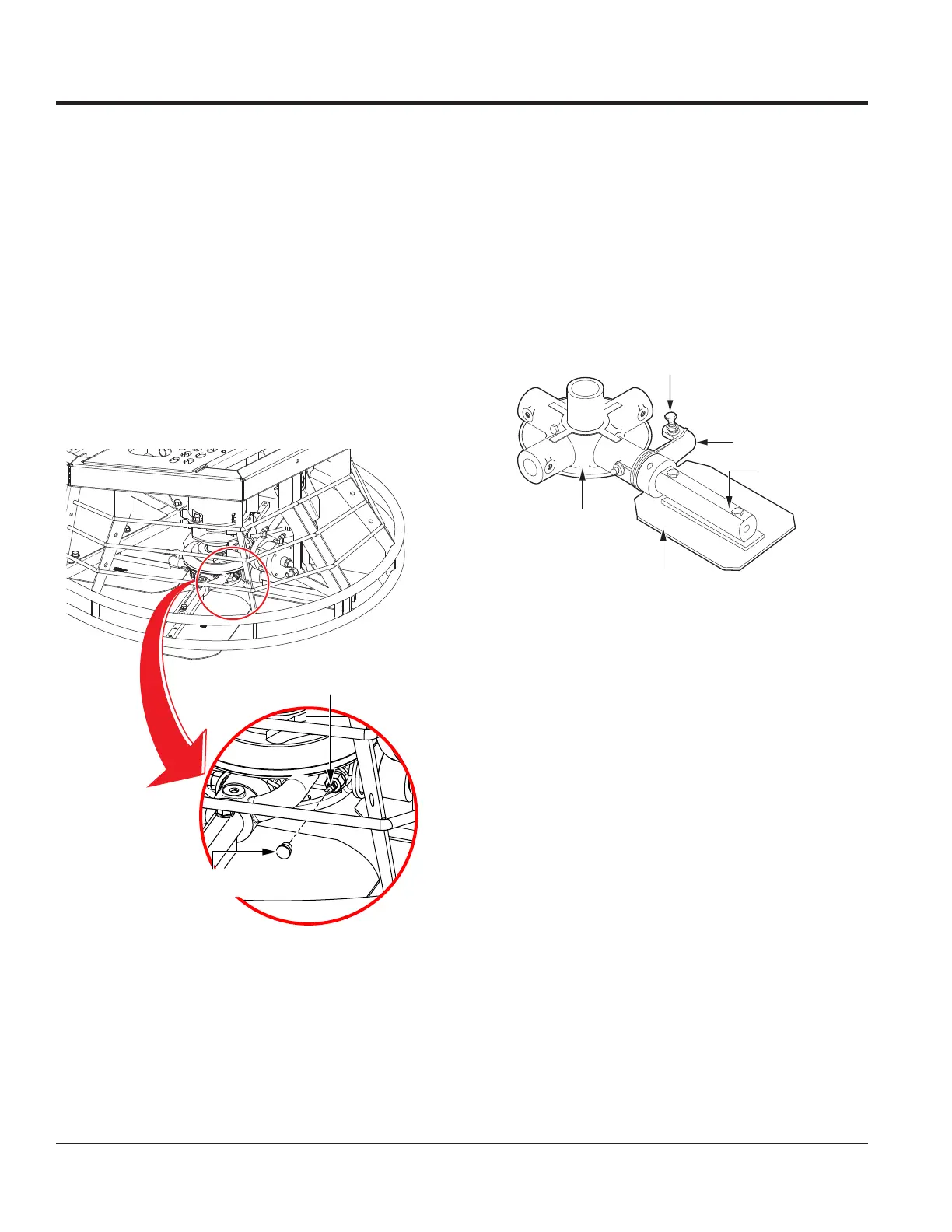

BLADE PITCH ADJUSTMENT

Perform maintenance adjustment of blade pitch using a

bolt on the trowel arm lever (Figure 41). This bolt is the

contact point of the trowel arm with the lower wear plate

on the thrust collar. The goal of adjustment is consistent

blade pitch and finishing quality.

Figure 41. Blade Pitch Adjustment Bolt

Look for the following indications when determining if blade

pitch adjustment is necessary:

Are the blades wearing out unevenly (e.g. one blade is

completely worn out while the others look new)?

Does the machine have a perceptible rolling or bouncing

motion while in use?

Does the guard ring rock up and down while the machine

is in use?

Once it has been determined that blade pitch adjustment

is necessary, do the following:

1. Place the trowel on a flat, level surface, with blocks

under the main guard ring for support. Any uneven

spots in the floor or debris under the trowel blades will

cause an incorrect perception of adjustment. Ideally,

a 5 ft. × 5 ft. (1.5 m × 1.5 m), 3/4 inch-thick, flat steel

plate should be used.

SPIDER

PLATE

BLADE PITCH

ADJUSTMENT

BOLT

TROWEL

ARM

TROWEL ARM

LEVER

TROWEL

BLADE

MAINTENANCE

CLEANUP

NEVER allow concrete to harden on the trowel. Wash any

concrete off the trowel with water immediately after use.

Be careful to not spray a hot engine or muffler. An old paint

brush or broom may help loosen any concrete that has

started to harden.

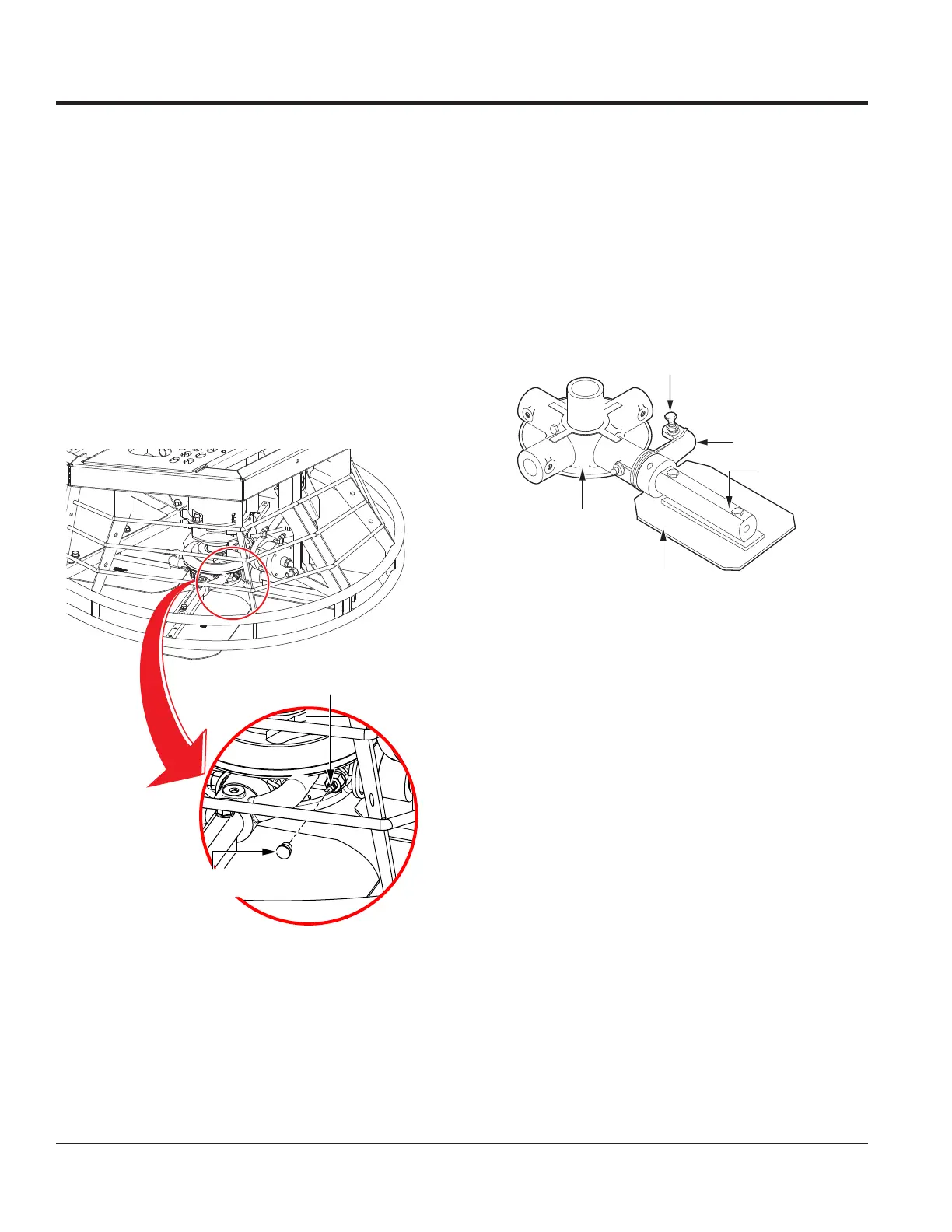

TROWEL LUBRICATION

Regular lubrication is required to maintain your trowel in

optimal working condition. Perform the following lubrication

procedure after every 8 hours of operation.

1. Locate one of the Zerk grease fittings on either spider

assembly (Figure 40). Remove the Zerk fitting cap and

set it aside.

Figure 40. Spider Lubrication

2. Wipe the Zerk grease fitting clean to prevent abrasive

material from entering the fitting during lubrication.

3. Lubricate the Zerk grease fitting with 1–1½ shots of

multipurpose grade grease. Replace the Zerk grease

fitting cap when finished.

ZERK GREASE

FITTING

ZERK

FITTING CAP

Loading...

Loading...