Description

Process sequence

26 11.06.2014

Evacuation Evacuation if chamber and film pouches.

Gas flushing (option) Infeed of inert gas.

Sealing Sealing of film pouches.

2.6 Times which have to be set

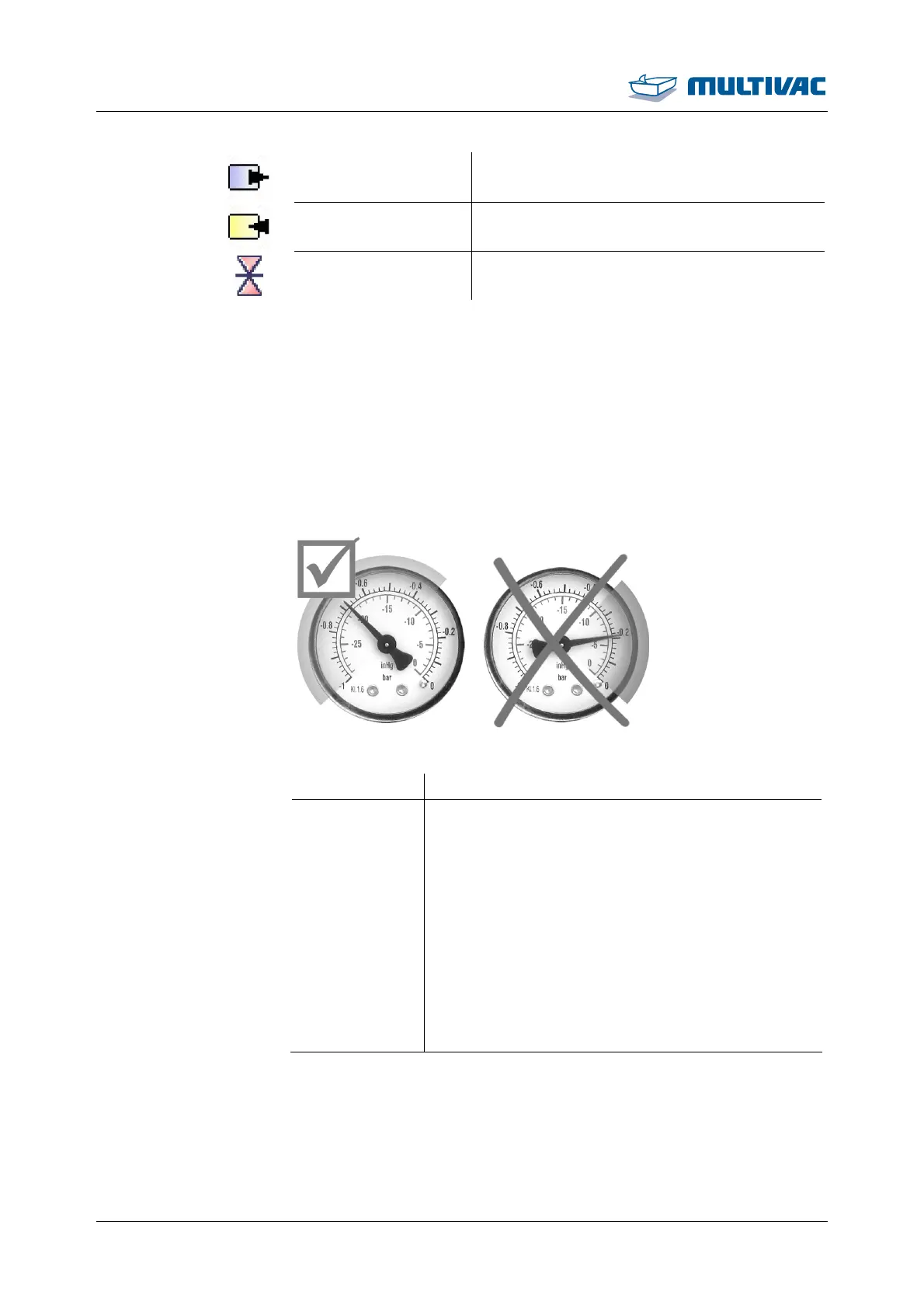

Times must be set for evacuation, gas flushing and sealing. The

times depend on the product and the film pouch used. A pressure

difference of at least -0.35 bar is required during the evacuation and

gas flushing processes, so that the chamber lid remains closed. A

pressure difference of at least -0.35 bar is also required before the

sealing process, so that the film pouches can be sealed. The pres-

sure difference can be read at the pressure display on the machine

control.

Fig. 11: Areas on the pressure display

Time Explanation

Evacuation time Air is suctioned out of the chamber and the film

pouches during this time. The longer the evacua-

tion time, the better the vacuum and the quality of

the seal seam. Too long an evacuation time can

damage sensitive products (e.g. raw or pre-cooked

pasta, cooked vegetables). In the case of liquid

products, the evacuation process should be

stopped with the <Stop> key shortly before the

product begins to boil.

Recommended value: at least 3 s

In the case of a packaging procedure with gas

flushing, the evacuation time must be extended.

Loading...

Loading...