Operation

Packing products

46 11.06.2014

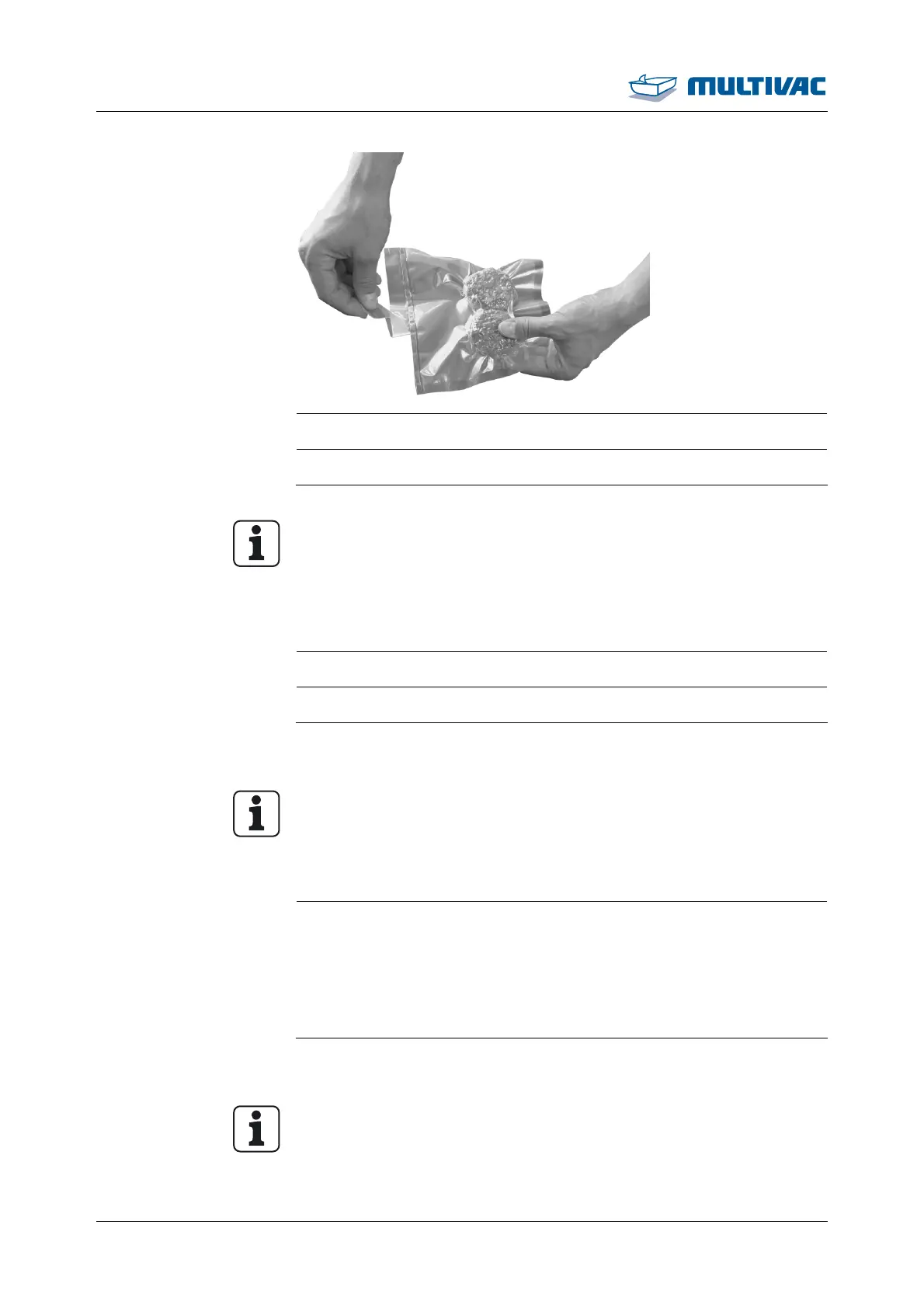

¾ Detach the pouch neck.

¾ Check the pack.

Info

Visually inspect the packs on a regular basis while the machine is

running. Depending on product and pack it may be necessary to

carry out additional and considerably more complex test proce-

dures. This is the responsibility of the operating company, see Sec-

tion 1.7.11 "C

HECKING THE PACKS".

¾ If necessary, adapt the times to the product.

¾ Save recipe, see Section 4.8.2 "SAVE RECIPE".

4.6 Aborting evacuation

Info

Vacuum lowers the boiling point of liquids. This means that liquid

products can boil during the evacuation process. The boiling prod-

uct contaminates the film pouch in the area of the seal seam and

the film pouch can therefore no longer be sealed.

¾ If the product begins to boil during the evacuation process, abort

the evacuation process with the <Stop> key.

– With machines without inert gas: the film pouch is sealed. The

chamber lid then opens automatically.

– With machines with inert gas: the film pouch is gas flushed and

sealed. The chamber lid then opens automatically.

4.7 Aborting packaging procedure

Info

The packaging procedure can be aborted at any time (e.g. the film

pouch has slipped out of position or the packaging procedure was

started with the incorrect recipe).

Loading...

Loading...