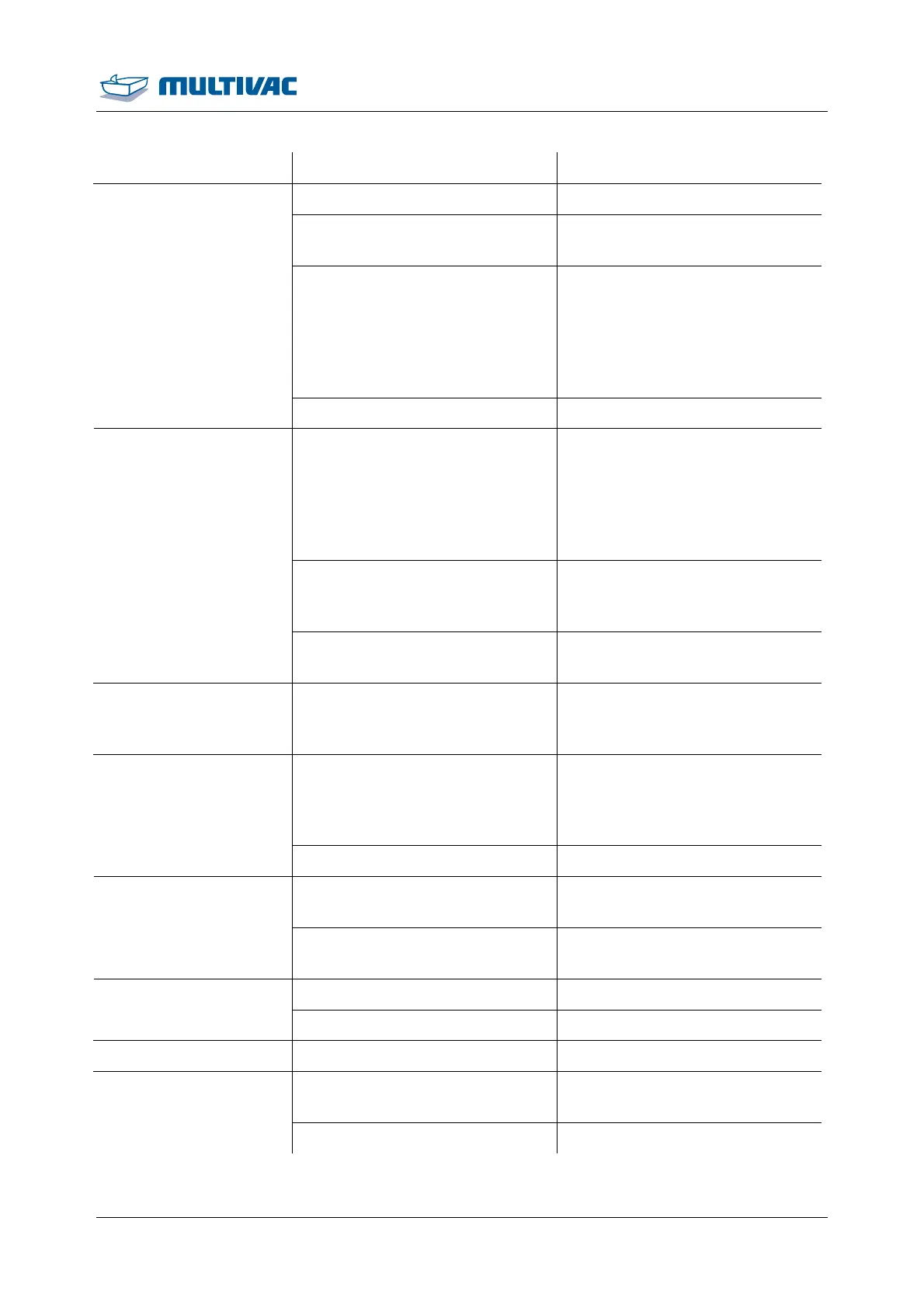

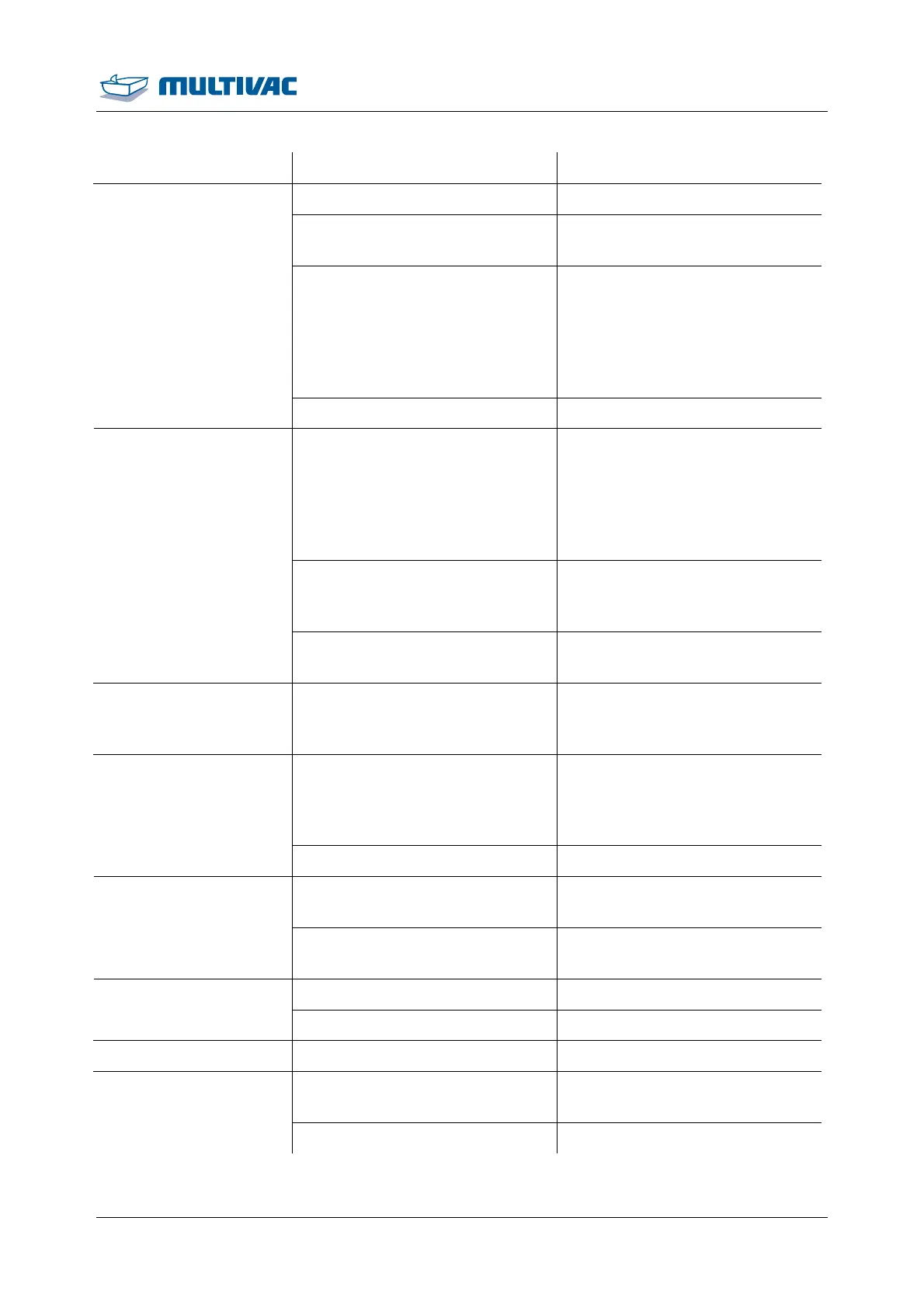

Troubleshooting

Faults without diagnostic message

11.06.2014 79

Symptom Cause Solution

• Film pouch damaged. • Use a new film pouch.

• Film pouch not suitable. • Use a film pouch suitable for

sealing.

• The pressure difference be-

tween the chamber and the

outside environment is not

large enough before the seal-

ing process.

• Set the evacuation time and

gas flushing time such that the

pressure display shows a

pressure difference of at least

0.35 bar before the sealing

process.

• Sealing bar damaged. • Replace sealing bar.

• The pressure difference be-

tween the chamber and the

outside environment is not

large enough before the seal-

ing process.

• Set the evacuation time and

gas flushing time such that the

pressure display shows a

pressure difference of at least

0.35 bar before the sealing

process.

• Teflon tapes on the sealing

bar and counter-pressure bar

are worn.

• Change the Teflon tapes.

Seal seam is uneven

and wavy.

• Profile thread in the counter-

pressure bar is worn.

• Repair the counter-pressure

bar.

Seal seam is milky. • Sealing time is set incorrectly. • Reduce the sealing time. The

seal seam should be clear and

transparent.

• Sealing time is set incorrectly. • Increase the sealing time in

small increments. The excess

pouch neck should be easy to

sever.

The excess pouch neck

can only be severed with

difficulty at the sever

seal or it can not be

severed at all.

• Sealing bar damaged. • Replace sealing bar.

• Air de-oiling element is defec-

tive.

• Change air de-oiling element. Odour or smoke.

• Oil return valve of vacuum

pump is clogged.

• Notify the service.

• Air de-oiling element clogged. • Change air de-oiling element. Machine is very loud.

• Vacuum pump defective. • Notify the service.

High oil consumption. • Air de-oiling element clogged. • Change air de-oiling element.

• Screw plugs or oil sight glass

not tight.

• Tighten screw plugs and oil

sight glass.

Oil leaks out of machine.

• Vacuum pump defective. • Notify the service.

Loading...

Loading...