Setup and connection

5.2 Setup with foundation

CAUTION

Material damage due to base plate distortion!

Set and fasten the base plate on the foundati on as

described in the following.

5.2.1 Setting the pump aggregate on the foundation

✔ Implements, tools and materials:

– foundation bolts (→ Setup drawing)

– steel washers

– mortar grout, non-shrinking

– spirit level

1. Lift the pump aggregate (→ 4.1 Transport, Page 13).

2. Working from below, hang the foundation bolts in the fixa-

tion holes of the base plate.

Observe the manufacturer's instruction when using chem-

ical anchors.

3. Set down the pump aggregate on the foundation. When

doing this, sink the foundation bolts into the prepared

anchoring holes.

32 1 2

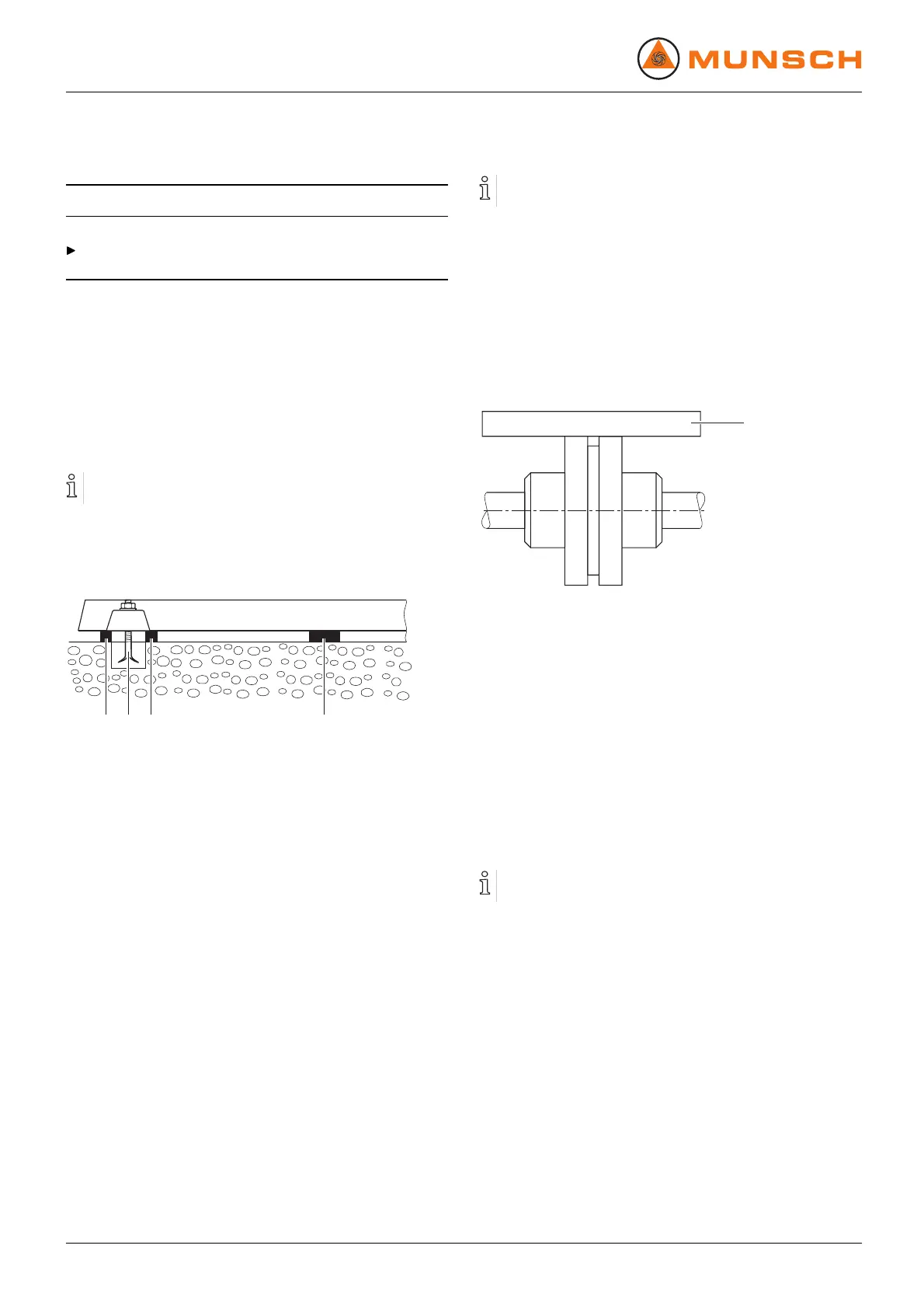

Fig. 9 Setup with foundation

4. Use steel washers to align the pump aggregate to height

and system measures as described in the following:

– Position 1 steel washer (2) each lef t and right of each

foundation bolt (1).

– If the distance between anchoring holes is > 750 m m,

position additional steel washer (3) centrally at each

side of the base plate.

5. Make certain that the base plate and the steel washers are

in full surface contact.

6. Use machine spirit level to check that the allowable height

deviation (1 mm/m) lengthwise and crosswise is not

exceeded.

7. Repeat procedure until the base plate is correctly aligned.

5.2.2 Fastening the pump aggregate

Filling out the base plate with mortar grout will improve the

damping behavior.

1. Fill the anchoring holes with mortar grout.

2. Once the mortar grout has set, screw on the base

plate at three points with the specified tightening torque

(→ 9.2.4 Tightening torques, Page 41).

3. Before tightening the remaining bolts, compensate any

unevenness of the fixation surface, using metal shims n ext

to each bolt.

4. To inspect the pump aggregate for distortions, using a hair

ruler:

1

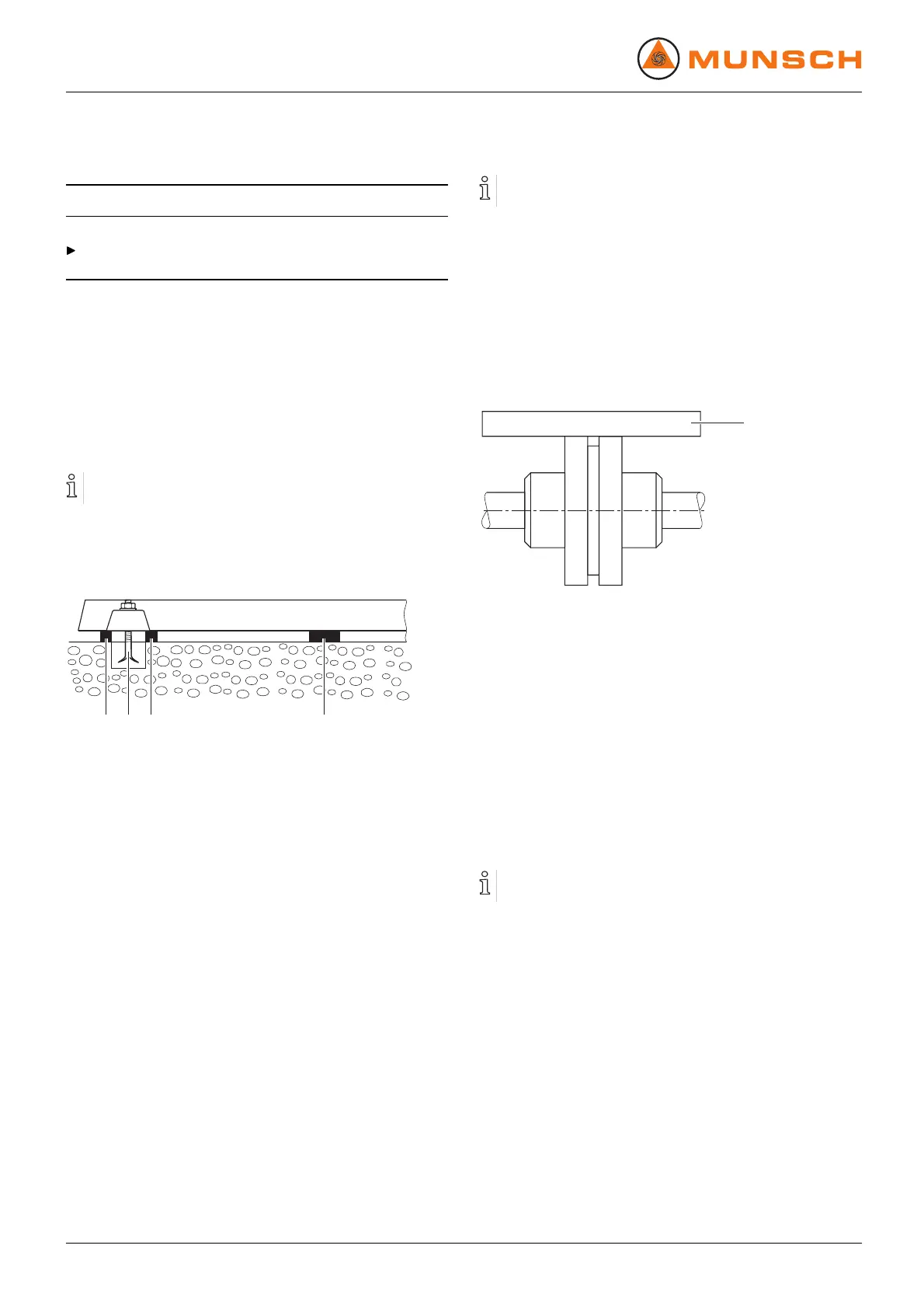

Fig. 10 Checking for distortions

– Measure in two planes at an angle of 90° to each other

on the circumference of the coupling.

– Measure the light gap at the outer diameter with hair

ruler (1):

Position the hair ruler across both halves of the cou-

pling.

If there are major deviations, loosen the fixation at the

base plate and correct the distortion by inserting more

shims.

– Fill the base plate with molding material if applicable.

Knock on the base plate to ensure that no cavities are

created in the process.

Couplings with a spacer piece (Dismountable coupling ) can

also be inspected with a dial gauge.

16 NPC series BA-2005.07 EN – 02

Loading...

Loading...