Setup and connection

5.5.3 Specifying nominal widths

Keep flow resistance in pipes as low as possible.

1. Specify suction pipe nominal width ≥ suction flange nominal

width.

2. Specify pressure pipe nominal width ≥ pressure flange

nominal width.

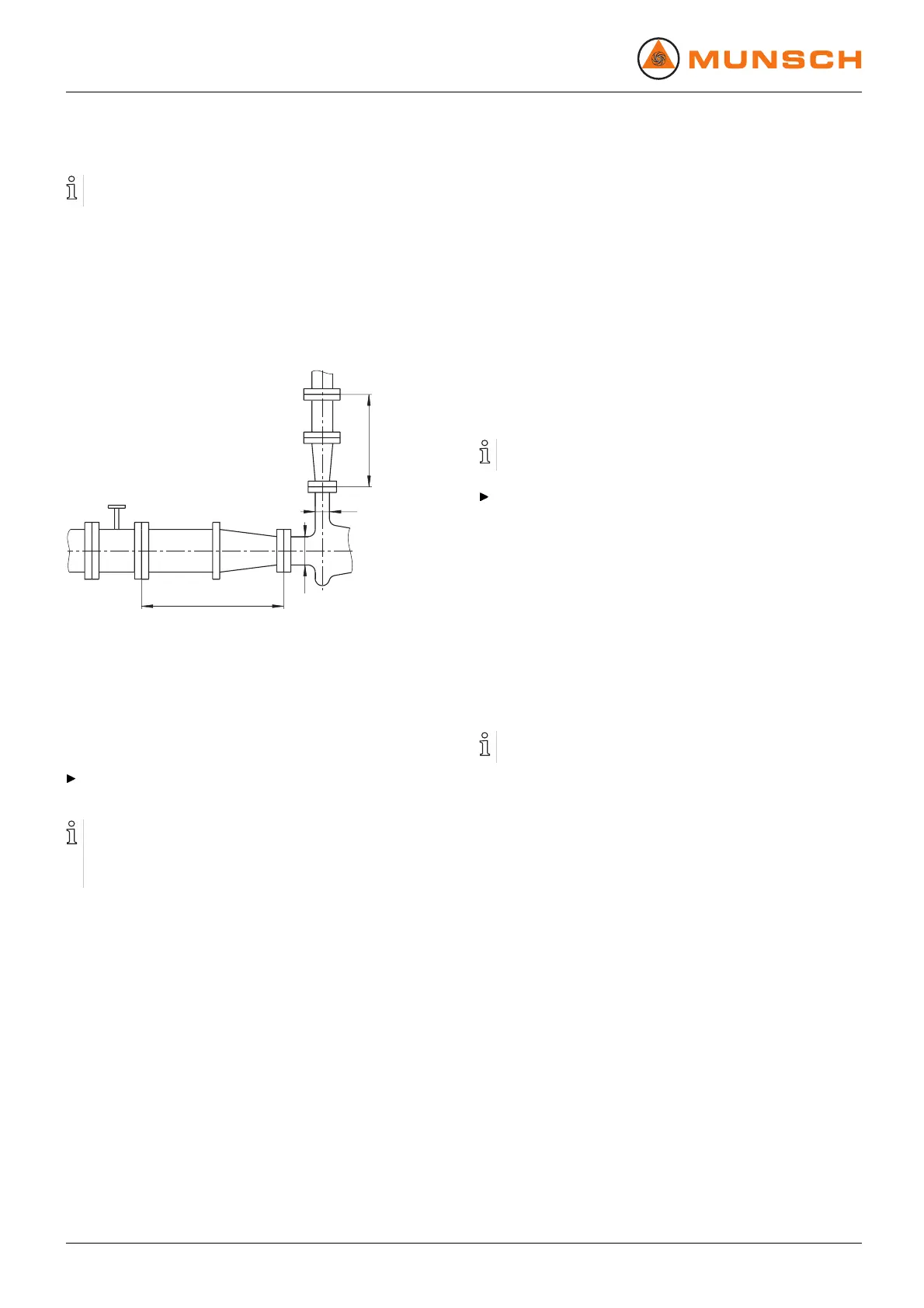

5.5.4 Specifying pipe lengths

C

D

B

A

Fig. 12 Straight pipe lengths upstream and downstream

of the pump (recommended)

A>5xDNs

B DNs

C DNd

D>5xDNd

Observe recommended m inimum parameters when install-

ing the pump.

Suction side: Shorter pipes are allowable but can restrict

hydraulic performance data.

Pressure side: Shorter pipes are allowable but can lead to

increased operating noise.

5.5.5 Optimizing cross-section and direction changes

1. Avoid radii of curvature smaller than 1.5 times the nominal

pipe width.

2. Avoid abrupt changes of cross-section along the piping

system.

5.5.6 Arranging for safety and control devices

(recommended)

Avoiding contamination

1. Integrate filter into the suction pipe.

2. To monitor contamination, m ount a differential pressure

gage with a contact manometer.

Avoiding rev erse running

1. Install a check valve between the pressure socket and the

gate valve to ensure that the medium will not flow back

whenthepumpisswitchedoff.

2. To allow bleeding, provide a bleeding connection between

the pressure socket and the check valve.

Providing for isolating and shut-off devices for the pipes

For maintenance and r epair work.

Provide for shut-off devices in the suction and pressure

pipes.

Allowing the measurement of the operating conditions

1. Provide for manometers for p ressure measurements in

suction and pressure pipes.

2. Provide for motor-side torque measurement.

3. Provide for pump-side temperature measurement.

5.6 Connecting the pipes

5.6.1 Installing auxiliary pipes

Follow manufacturers' specifications of any existing auxil-

iary operating system.

1. Install auxiliary piping to auxiliary unions, ensuring stress-

free and sealed connections (→ Setup drawing).

2. To avoid air enclosures: run pipes with a continuous slope

up to the pump.

5.6.2 Installing the suction pipe

1. Remove transport and sealing covers at the pump.

2. To avoid air enclosures: run pipes with a continuous slope

up to the pump.

3. Ensure that no gaskets are protruding inwards.

4. For suction ope ration: Install a foot valve in t he suction line

to prevent the pump an d suction pipe from running em pty

during downtime.

5.6.3 Installing the pressure pipe

1. Remove transport and sealing covers at the pump.

2. Mount the pressure pipe.

3. Ensure that no gaskets are protruding inwards.

18 NPC series BA-2005.07 EN – 02

Loading...

Loading...