Maintenance

7.3.1 Returning the pump to the m anufacturer

✔ Pump is unpressurized

✔ Pump is completely empty

✔ Electrical connecti ons are isolated and the mo tor is

secured against switch-on

✔ Pump has cooled down

✔ Coupling shield is dismounted

✔ For couplings with a spacer piece: spacer piece is removed

✔ Auxiliary operating systems are shut down, unpressurized

and emptied

✔ Manometer connections, manometer and fixtures are dis-

mounted

1. Always enclose a truthfully completed safety certificate

when returning pumps or com ponents to the manufact urer.

Order a safety certificate from the manufacturer if required.

2. Take necessary measures, depending on the required

repair work, as listed in the table below for returning the

pump to the manufa cturer.

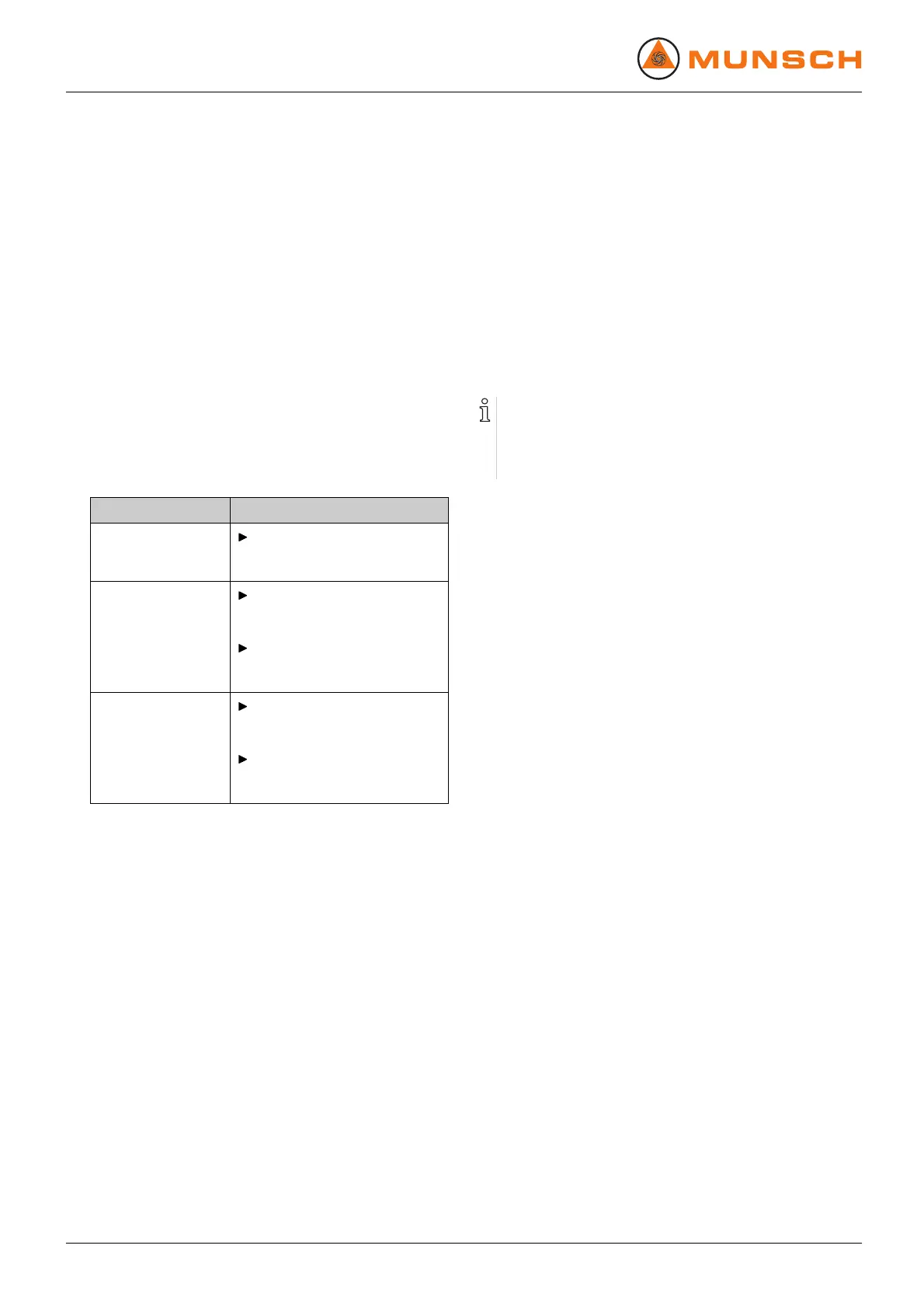

Repair carried out

Action for return

at customer's

premises

Return the defective

component to the

manufacturer.

at manufacturer's

premises

Flush the pump and

decontaminate if hazardous

media were pumped.

Return the complete pump

(not disassembled) to the

manufacturer.

at manufacturer's

premises for

warranty repairs

For hazardous pumped

media only: flush and

decontaminate the pump.

Return the complete pump

(not disassembled) to the

manufacturer.

Tab. 11 Actions for return

7.3.2 Preparations for disassembling

✔ Pump is unpressurized

✔ Pump is completely empty, flushed and decontaminated

✔ Electrical connecti ons are isolated and the mo tor is

secured against switch-on

✔ Pump has cooled down

✔ Coupling shield is dismounted

✔ For couplings with a spacer piece: spacer piece is removed

✔ Auxiliary operating systems are shut down, unpressurized

and emptied

✔ Manometer connections, manometer and fixtures are dis-

mounted

The pumps are constructed in process archite cture as stan-

dard. The slide-in unit can be dismounted without removing

the volute casing and piping.

If a coupling with a spacer piece is used, the motor can

remain mounted on the base pl ate.

1. For disassembling take note of the following:

– Precisely mark the assembly orientation and position

of all components before disassembly.

– Dismount components concentrically without canting.

– Disassemble the pump (→ S ectional drawing).

2. Loosen the fixation bolts of support foot 183 and casing

feet 187.

3. Lift the pump out of the installation (→ 4.1.2 Lifting,

Page 13).

26 NPC series BA-2005.07 EN – 02

Loading...

Loading...