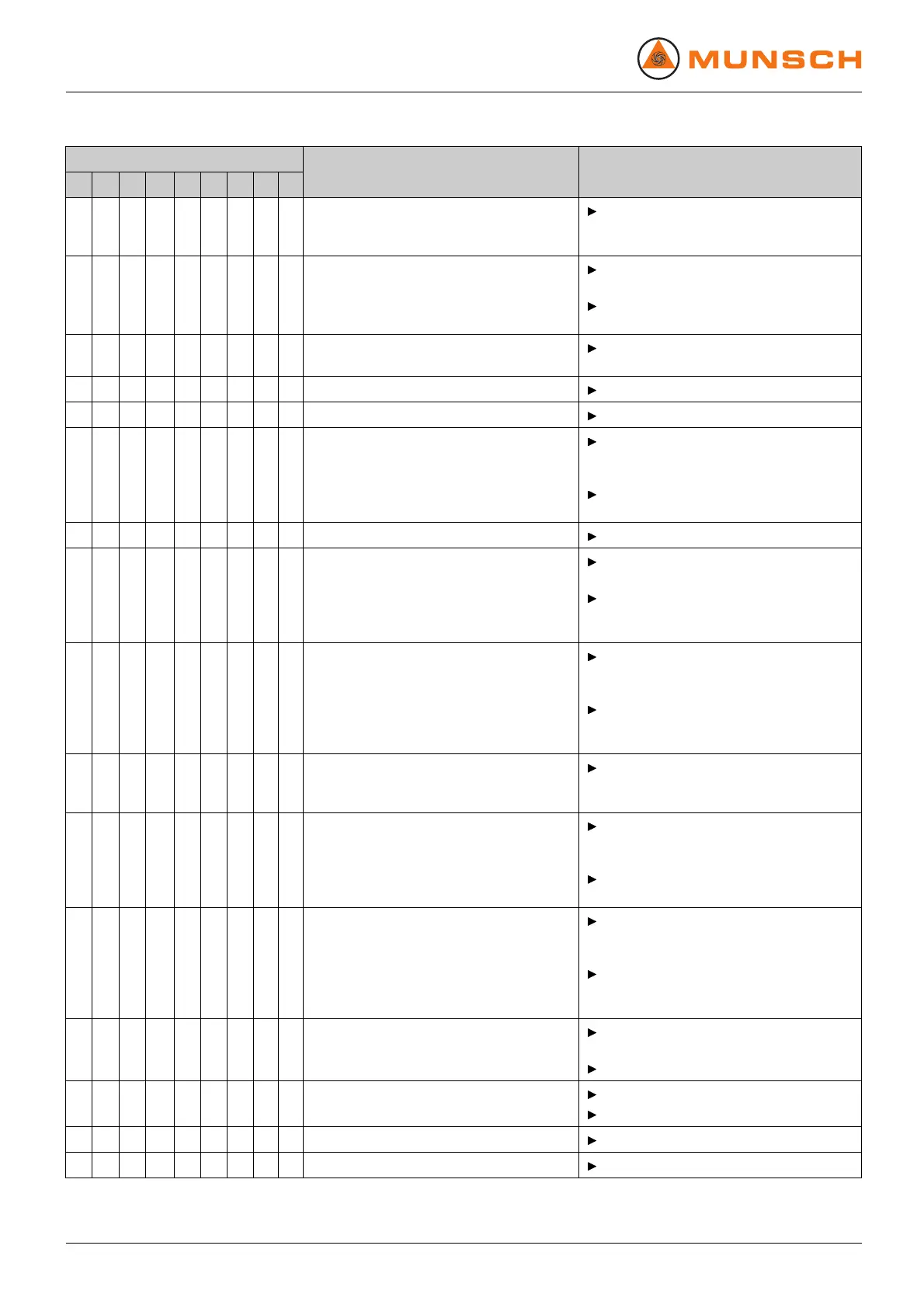

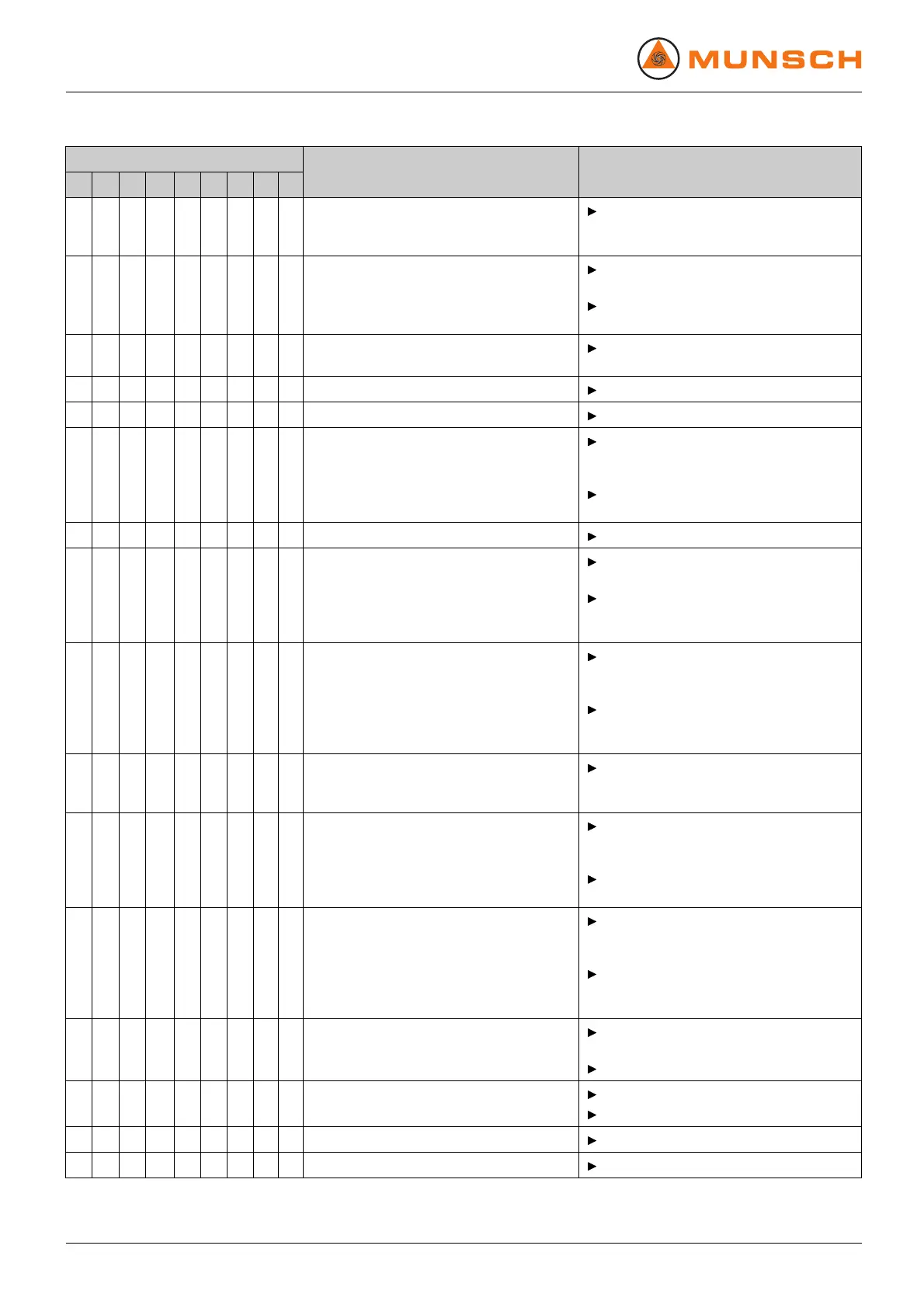

Disturbance recovery

Fault number

12 34

5

6

7

89

Cause

Remedy

–

X

–

X

––––

X

Viscosity or density of the pumped

medium outside the specification range

for the pump

Consult with manufacturer.

–

X

–

X

–––––

Geodetic differential head and/or pipe flow

resistance too high

Remove sediments in pump and/or

pressure pipe.

Install larger impeller and consult with

manufacturer.

–

X

––

XX

–––

Pressure-side armature not opened

sufficiently

Open the pressure-side armature.

XX

––

XX

–––

Pressure pipe blocked

Clean the pressure pipe.

XX

–

X

–

X

–––

Pump running the w rong direction

Swap any two phases at the motor.

XX

–

X

–––––

Motor speed insufficient

Compare required motor speed w ith

specification on pump type plate.

Replace motor if necessary.

Increase motor speed with speed

control if available.

–

X

–

X

–

XX

––

Pump components worn

Replace worn pump components.

––

XX

–

X

––

X Pressure-side armature opened too wide

Throttle down at pressure-side

armature.

Mill down the impeller. Consult with

manufacturer and adjust impeller

diameter.

––

X

––

X

––

X

Geodetic differential head, pipe flow

resistance and/or other resistance lower

than specified

Throttle down flow rate at pressure-si de

armature. Observe the minimum flow

rate limit.

Mill down the impeller. Consult with

manufacturer and adjust impeller

diameter.

––

X

–

X

––––

Viscosity lower than expected

Mill down the impeller. Consult with

manufacturer and adjust impeller

diameter.

––

X

–

XXX

–

X Motor speed excessively high

Compare required motor speed w ith

specification on pump type plate.

Replace motor if necessary.

Reduce mo tor speed with speed control

if available.

––

X

–

XX

––

X Impeller diameter too large

Throttle down flow rate at pressure-si de

armature. Observe the minimum flow

rate limit.

Mill down the impeller. Consult with

manufacturer and adjust impeller

diameter.

XX

–

X

–

X

–––

Impeller out of balance or clocked

Disassemble pump and inspect for

dry-running damage.

Clean the impeller.

–

X

–

X

–

X

–––

Hydraulic components of the pump dirty,

clotted or encrusted

Disassemble pump.

Clean the components.

–– –– –

XX

–

X

Roller bearing in bearing bracket defective

Replace roller bearing.

–– –– ––

X

–

X

Roller bearing in motor defective

Replace roller bearing.

32 NPC series BA-2005.07 EN – 02

Loading...

Loading...