MG50&MG90

2Dehumidierdesign

2.1Productdescription

Thedesiccantdehumidiersaredesignedtoeffectivelydehumidifytheair.Theircompactformis

comprisedofsectionsthatareheldtogetherwithjustfourbolts.Thefan,desiccantrotorandreactivation

heaterareheldintheirrespectivesectionswithoutanyfurthermeansofattachment.Oneofthesections

containsadistributionchamberwithinsulatedsectionsthatprovideexactlytherightbalancebetweenthe

dehumidifyingandreactivationairows.Thesturdyoutercasingismadeofcorrosionresistant,die-cast

aluminium.

TheelectricalequipmentcomplieswiththeEN60204-1standard.Thedehumidierismanufactured

accordingtouniformEuropeanstandardsandtheestablishedrequirementsforCE-marking.

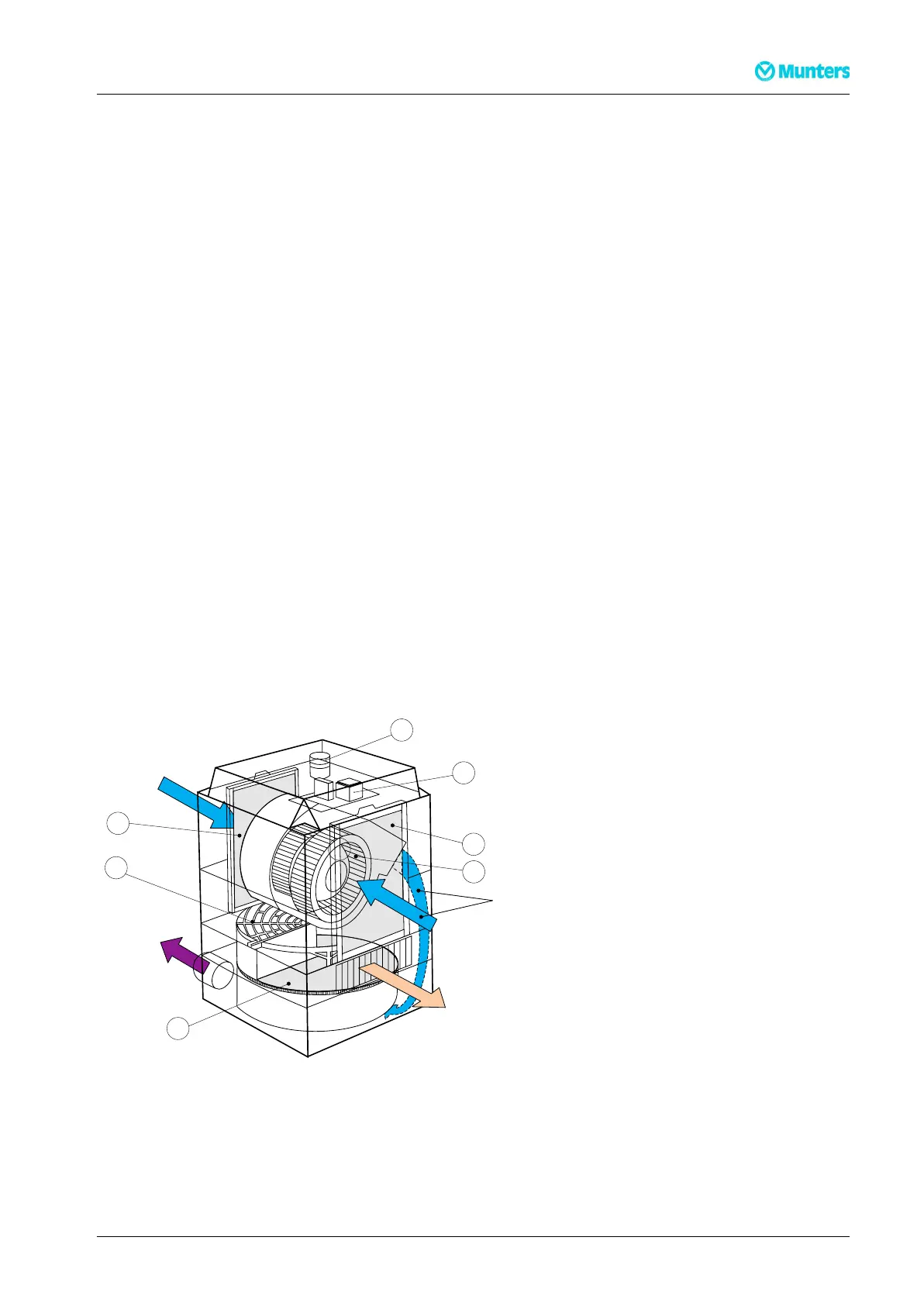

2.2Principleofoperation

Thedesiccantrotoristheadsorptiondehumidifyingcomponentintheunit.Therotorstructureis

comprisedofalargenumberofsmallairchannels.

Thedesiccantrotorismadeofacompositematerialthatishighlyeffectiveinattractingandretainingwater

vapour.Therotorisdividedintwozones.Theairowtobedehumidied,processair,passesthroughthe

largestzoneoftherotorandthenleavestherotorasdryair.Sincetherotorrotatesslowly,theincomingair

alwaysmeetsadryzoneontherotor,thuscreatingacontinuousdehumidicationprocess.

Theairowthatisusedtodrytherotor,reactivationair,isheated.Thereactivationairpassesthrough

therotorintheoppositedirectiontotheprocessairandleavestherotoraswetair(warm,moistair).This

principleenablesthedehumidiertoworkeffectively,evenatfreezingtemperatures.

1.Filter

2.Heater

3.Rotor

4.Drivemotor

5.Circuitboard

6.Filter

7.Impeller

A.Reactivationair

B.Wetair

C.Processair

Figure2.1Principleofoperation

D.Dryair

190TGB-1004–N1402Dehumidierdesign4

Loading...

Loading...