MX

2

Plus Dehumidification system

4 Main components description

NOTE! Some components are optional, and individual systems are built

to

specification.

NOTE! All component pictures are examples, and may not correspond

to

individual

units.

4.1

Dehumidifier

4.1.1

Principle

of

operation

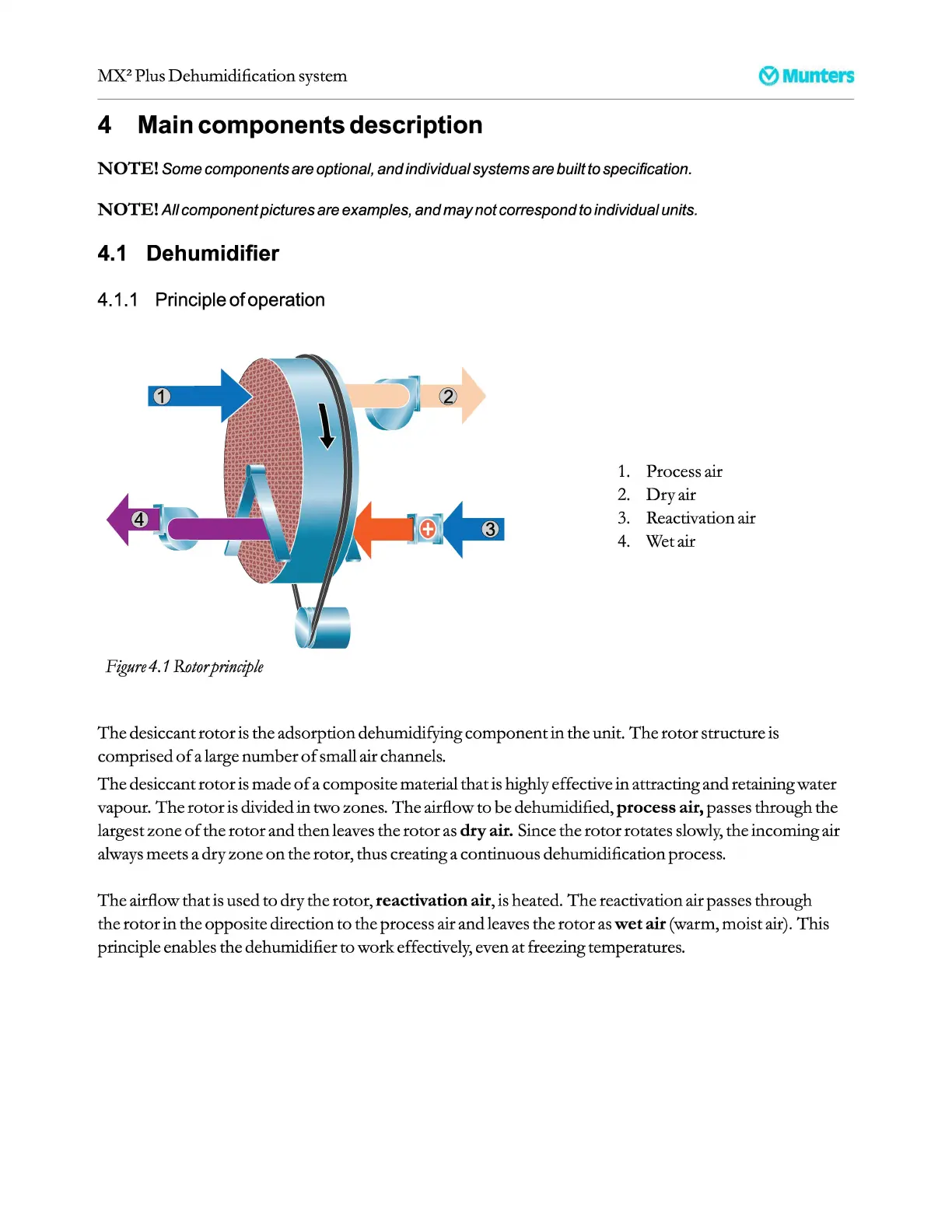

1.

Process air

~

2.

Dry

air

I~

3.

Reactivation air

4.

Wet air

Figure4.1

R!Jtorprinciple

®Munters

The

desiccant

rotor

is the adsorption dehumidifying

component

in the unit.

The

rotor

structure is

comprised

of

a large

number

of

small air channels.

The

desiccant

rotor

is

made

of

a composite material

that

is highly effective in attracting

and

retaining water

vapour.

The

rotor

is divided in two zones.

The

airflow

to

be

dehumidified,

process

air, passes

through

the

largest

zone

of

the

rotor

and

then

leaves the

rotor

as

dry

air.

Since

the

rotor

rotates slowly,

the

incoming air

always meets a dry

zone

on

the

rotor, thus creating a continuous dehumidification process.

The

airflow that is used

to

dry the rotor, reactivation air, is heated.

The

reactivation air passes

through

the

rotor

in

the

opposite direction

to

the

process air

and

leaves

the

rotor

as

wet

air (warm,

moist

air). This

principle enables the dehumidifier

to

work effectively, even

at

freezing temperatures.

Loading...

Loading...