2201Q4JE-MY-C9-N_2018.01.

Chapter 7 Related Documents

Compound 2-stage Screw Compressor 4032**C About the O-rings Used

7-15

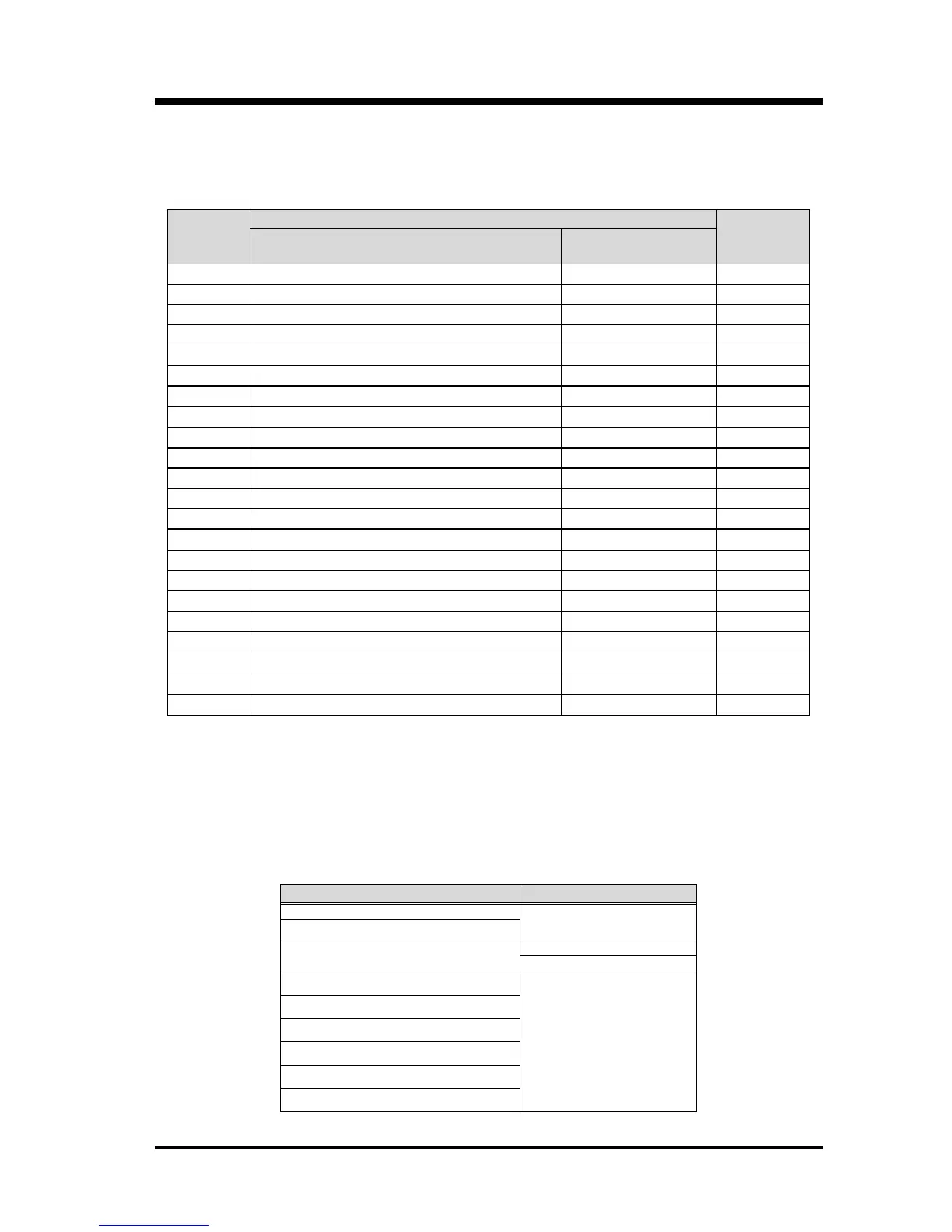

7.4 About the O-rings Used

7.4.1 List of O-rings Used

Table 7-4 List of O-rings Used

description in

functional aspect

Seal Cover for BOD type Mechanical Seal

Note 1: Attached place means parts which they have grooves or with taper cutting for attaching O-ring.

Note 2: AS568A 261(Old JIS W1516 G39)

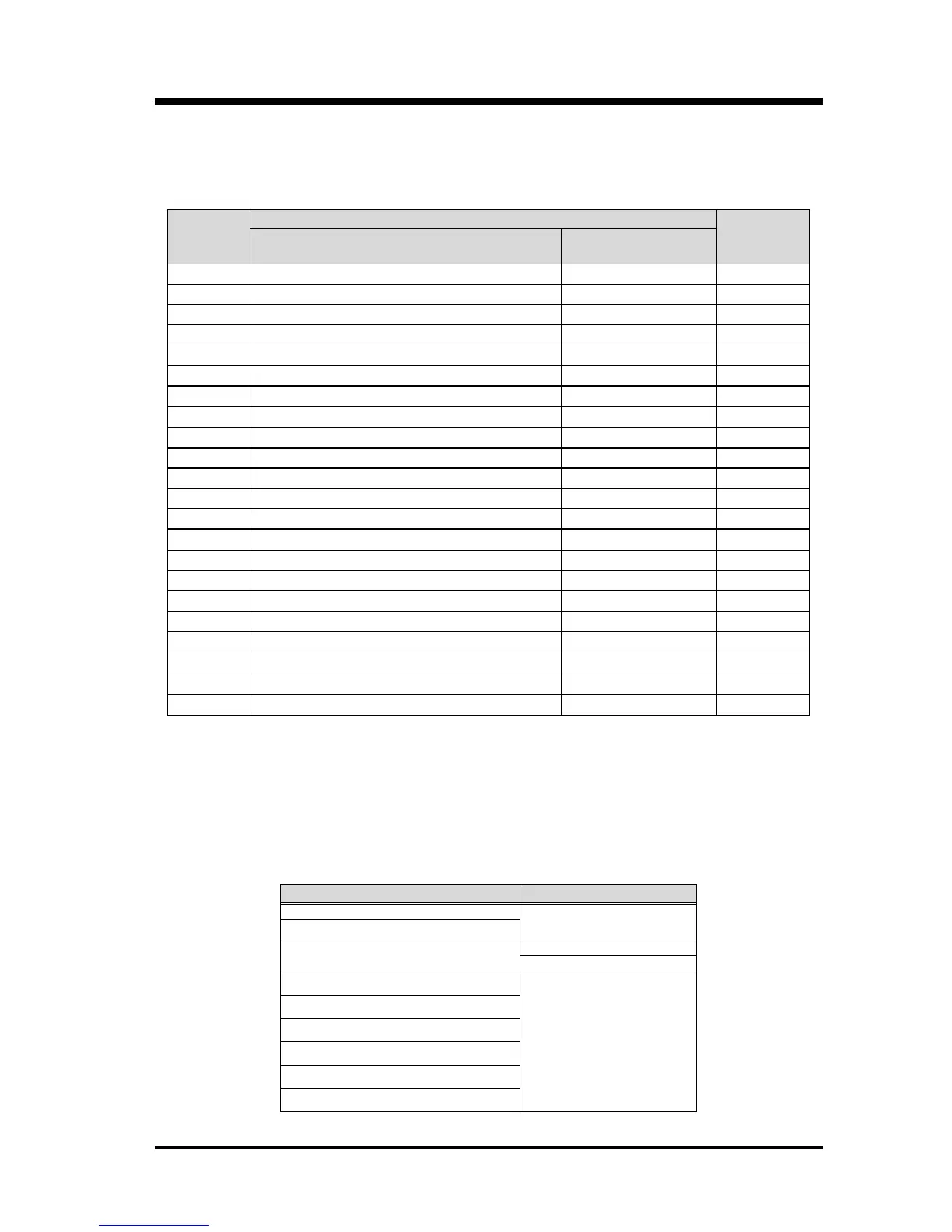

7.4.2 O-ring Materials Used for Screw Compressor

Table 7-4 List of O-ring Materials Used for Screw Compressor

(excluding mechanical seal)

Loading...

Loading...